-

E-mail

1225767627@qq.com

-

Phone

13581986832

-

Address

Shahewangzhuang Industrial Park, Changping District, Beijing

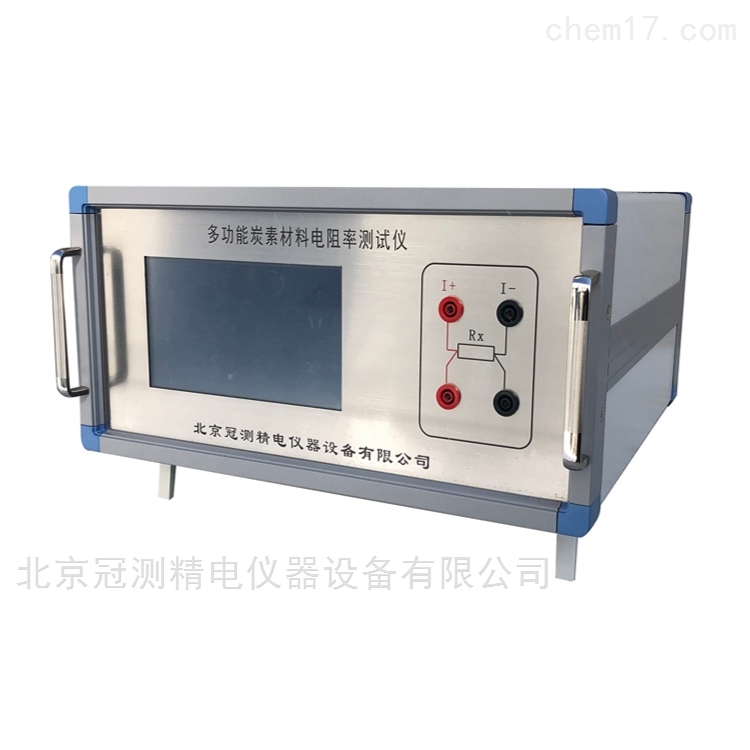

Beijing Guance Jingdian Instrument Equipment Co., Ltd

Key technologies and methods for accurately measuring the resistivity of carbon materials

The measurement of electrical resistivity of carbon materials is an important part of materials science research, and its accuracy directly affects the evaluation of material properties and application development. However, due to the diverse forms and complex conductive properties of carbon materials, traditional measurement methods often fail to meet the requirements. This article will explore the key technologies for measuring the resistivity of carbon materials, analyze the applicable scenarios of different methods, and look forward to future development directions.

1、 The main challenges in measuring the resistivity of carbon materials

There are various types of carbon materials, ranging from graphene and carbon nanotubes to porous carbon and carbon fibers, with significant differences in their morphology and conductivity. The main challenges faced during measurement are as follows:

Morphological diversity: Measurement methods that need to be adapted to different forms such as films, powders, and blocks.

Contact issue: The contact resistance between the probe and the material surface may introduce errors.

Anisotropy: Some materials exhibit significant differences in conductivity in different directions.

Environmental dependence: Environmental factors such as temperature and humidity may affect measurement results.

2、 Mainstream measurement methods and their applicability

At present, the resistivity measurement of carbon materials mainly adopts the following methods, each with its own advantages and limitations.

1. Four probe method

The four probe method effectively reduces the influence of contact resistance by separating current injection and voltage detection, and is suitable for bulk and thin film materials. Its advantage lies in high measurement stability, especially suitable for carbon materials with good conductivity. However, for ultra-thin or flexible samples, attention should be paid to the potential damage of probe pressure to the sample.

2. Vanderbilt Law

The van der Waals method is applicable to thin film or sheet materials and can measure in-plane anisotropy. This method has low requirements for sample shape, but requires precise electrode arrangement and data processing. In recent years, by optimizing electrode design and algorithms, its measurement efficiency and accuracy have been improved.

3. Non contact measurement

The non-contact method does not require physical contact with the sample and is suitable for ultra-thin or fragile materials. Its advantage lies in avoiding probe interference, but the equipment cost is high and there are certain requirements for the surface flatness of the sample.

4. Measurement of variable temperature environment

The resistivity of many carbon materials varies significantly with temperature, so temperature dependent measurements are crucial for studying their conductivity mechanisms. By integrating a temperature control system, continuous measurements can be taken at different temperatures to reveal the thermal stability and conductivity behavior of materials.

3、 Optimization direction of measurement scheme

The measurement method needs to be flexibly adjusted according to the characteristics of different carbon materials:

Thin film materials: Prioritize non-contact or microprobe technology to reduce mechanical damage.

Porous/Powder Materials: Improve contact issues through compression molding or special electrode design.

Fiber/array materials: Combined with a rotating sample stage, study the anisotropic conductive properties.

In addition, the introduction of intelligent technology can further improve measurement efficiency and reliability.

4、 Future Development Trends

The future development of resistivity measurement technology for carbon materials will be in the following directions:

Higher accuracy: By optimizing probe design and signal processing algorithms, system errors are reduced.

Multi field coupling measurement: Combining environmental conditions such as mechanics and thermodynamics to simulate practical application scenarios.

Standardization and automation: Establish unified testing standards, develop high-throughput measurement systems, and meet industrial needs.