-

E-mail

huahui@shchylyqyxgs.wecom.work

-

Phone

15026706579

-

Address

No. 115, Lane 1276, Nanle Road, Songjiang District, Shanghai

Shanghai Chaohui Pressure Instrument Co., Ltd

In flammable and explosive industrial scenarios such as petrochemicals, coal mines, and power boilers, the safety and accuracy of pressure measurement are directly related to production safety and efficiency. The PT124B-281 series explosion-proof pressure transmitter is an ideal choice for such harsh environments due to its inherently safe explosion-proof design, corrosion resistance, and stable measurement performance. This article will comprehensively interpret this industrial pressure measurement "safety guard" from the aspects of product core highlights, applicable scenarios, technical parameters, installation and use precautions, etc.

1、 Core highlight: Hard power adapted to harsh environments

-Intrinsically safe explosion-proof, safeno blind spotThe product has an ExiaII CT4 intrinsic safety explosion-proof rating and can be directly applied to hazardous environments containing various flammable and explosive gases such as methane, ethane, hydrogen, etc. (Class II, Class C hazardous areas), eliminating potential safety hazards during the measurement process from the source and ensuring the safety of the production environment.

-Corrosion resistant and fully metal sealed, suitable for complex media: adopting a fully stainless steel shell design, paired with corrosion-resistant sensing membranes, it can not only resist the erosion of corrosive media such as hydraulic oil, natural gas, and chemical raw materials, but also achieve a gapless fully sealed structure with a protection level of IP65, effectively dustproof and waterproof, suitable for humid and dusty industrial sites.

-High precision+wide temperature compensation, more reliable measurement: equipped with high-quality piezoresistive sensor core, the comprehensive accuracy can reach 0.25% FS~0.5% FS, the linear error is as low as 0.02% FS, and the measurement data is accurate and stable. At the same time, it has a wide range of temperature compensation function, which can work stably in the medium temperature range of -10 ℃~70 ℃, and the environmental temperature adaptation range covers -40 ℃~125 ℃, effectively avoiding the influence of temperature fluctuations on measurement accuracy.

-Multiple protection design for longer service life: Built in reverse polarity protection, instantaneous overcurrent, overvoltage protection, and anti-interference protection circuits can effectively resist electrical interference and unexpected circuit failures in industrial sites, reducing the risk of equipment damage. The product also has an overload tolerance of 150% FS, which can ensure that the core components are not damaged and extend their service life even in the face of instantaneous pressure peaks.

-Visual operation, more convenient to use: optional LCD display screen, real-time and intuitive display of pressure data, no need to connect additional display devices to complete on-site readings. Simultaneously supporting 4-20mA standard output signals, it can easily interface with industrial control systems such as PLC and DCS to achieve remote monitoring and control of pressure data.

2、 Applicable scenarios: pressure measurement needs covering multiple industries

The PT124B-281 series is widely used in fluid pressure measurement and control in multiple industrial fields due to its excellent environmental adaptability and medium compatibility. Typical scenarios include:

Core application areas

-Petrochemical industry: pressure monitoring of crude oil pipelines, chemical reactors, and natural gas storage tanks

-Coal mines: pressure measurement of underground hydraulic systems and gas extraction pipelines

-Electric energy: boiler steam pressure, hydraulic system pressure control of generator set

-Hydraulic Machinery: Hydraulic System Pressure Feedback for Construction Machinery such as Excavators and Shield Tunnels

Expand application scenarios

-Shipbuilding industry: pressure monitoring of ship power systems and fuel pipelines

-Building automation:中央Pressure control of air conditioning water circulation system

-Rubber and Plastic Processing: High Temperature Melt Pressure Measurement of Extrusion Equipment (Suitable for High Temperature Models)

-Coal water slurry boiler: pressure monitoring of boiler feed pipeline

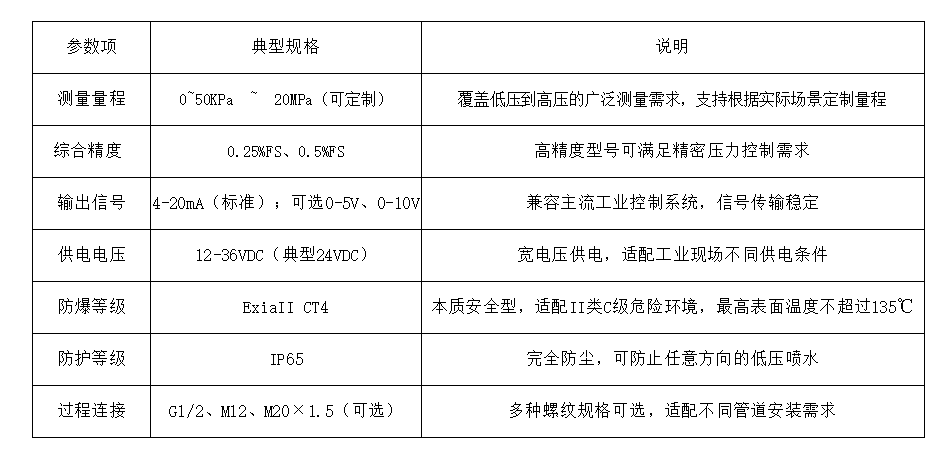

3、 Key technical parameters: Accurately match your usage needs

4、 Installation and usage precautions: Proper operation prolongs lifespan

1. Preparation before installation

-Check whether the appearance of the product is intact, verify that the product model, range, accuracy level and other parameters are consistent with the order requirements, and properly keep the product manual and certificate of conformity.

-Confirm that the hazardous area level of the installation environment matches the explosion-proof level of the product, and avoid using beyond the designated range.

-Check if the installation hole size meets the requirements, ensure that there are no metal foreign objects, plastic residues, or other impurities, and avoid damaging the sensing diaphragm during installation.

2. Installation points

-Be sure to protect the sensing membrane during installation to avoid collision and abrasion; The wrench can only be fitted onto the hexagonal wrench interface. It is forbidden to apply force on the outer tube or tail joint of the product to prevent damage to the internal structure.

-If measuring high-temperature media (such as high-temperature melts), it is necessary to ensure that the sensor probe extends into the high-temperature area, and the housing part is far away from the high-temperature area (the housing temperature resistance is ≤ 80 ℃), which can be fixed by a bracket to avoid overheating of the housing and affecting performance.

-When connecting cables, they need to be routed separately through wiring ducts to avoid parallel connection with strong electrical cables and reduce electromagnetic interference; Strictly follow the wiring diagram to ensure correct connection of positive and negative poles, and avoid damage to equipment caused by reverse polarity or overvoltage.

3. Use and maintenance

-To avoid long-term overload use, it is recommended to control the working pressure at 0.5-0.8 times the rated range. Even if the product has a 150% FS overload capacity, long-term overload will still affect measurement accuracy and lifespan.

-Regularly check whether the cable connection is secure, whether there is any damage or aging phenomenon; If the measuring medium is prone to crystallization and blockage, it is necessary to regularly clean the pressure hole. Organic solvents can be used to dissolve and clean, and it is forbidden to use containers to wipe inside the hole.

-When there is an abnormality in the equipment, immediately stop the machine for inspection. Do not disassemble or repair it yourself (there are no customer self repaired parts), and contact the after-sales service personnel in a timely manner.

4. Attention to special scenarios

When used on high-temperature equipment such as extruders, sufficient heating time should be reserved after installation to ensure the material is properly heatedcompletelyStart measuring after melting; Disassembly should also be carried out at the normal working temperature of the screw to avoid material solidification and damage to sensors and equipment.

5、 Selection suggestions and after-sales support

Selection suggestions

-Based on the corrosiveness and temperature of the measuring medium, select the corresponding material for the sensing diaphragm and installation method (such as selecting a high-temperature probe for high-temperature media).

-When specifying the measurement range, a certain margin should be reserved to avoid pressure fluctuations beyond the rated range.

-Select the output signal type according to the control system requirements (4-20mA is a universal choice), and confirm the thread specifications for the process connection.

After-sales service guarantee

Under normal use, the product is entitled to a 13 month warranty period (calculated from the date of shipment), during which non-human damage and malfunctions can be repaired free of charge; Repairs that exceed the warranty period will only incur labor costs, and lifelong maintenance services will be provided.

summary

The PT124B-281 series explosion-proof pressure transmitter has the core advantages of intrinsic safety, explosion-proof, corrosion resistance, high precision, and high stability,perfectAdapt to the pressure measurement needs of harsh industrial scenarios such as petrochemicals, coal mines, and electricity. The correct selection, installation, and maintenance can fully leverage its performance advantages, providing reliable guarantees for production safety and efficiency.

If you have specific application scenarios that require precise selection, or would like to learn more about product details, please feel free to leave a message in the comment section or contact our technical advisor!