-

E-mail

DS13564775333@163.com

-

Phone

13564775333

-

Address

1908 Liuxiang Road, Malu Town, Jiading District, Shanghai

Shanghai Huquan Valve Group Co., Ltd

Fault diagnosis and predictive maintenance of intrinsically safe electric ball valves for mining

Date: 2025-11-05Read: 4

As a key execution unit of the underground fluid control system in coal mines, the reliability of intrinsically safe electric ball valves for mining is directly related to the normal operation of safety systems such as ventilation, gas extraction, and drainage. Due to harsh environments such as high humidity, high dust, and flammability and explosiveness underground, electric ball valves are prone to mechanical jamming, seal failure, motor overload, and intrinsic safety circuit abnormalities. The traditional "post maintenance" or "regular inspection" mode is difficult to meet the requirements of modern intelligent mines for high availability and intrinsic safety.

The strict limitations on power consumption, voltage, and current in intrinsic safety design (usually ≤ 24 V, ≤ 100 mA) limit the driving capability of electric ball valves, and long-term operation is prone to problems such as wear, corrosion, and lubrication failure. Once a malfunction occurs, it not only affects the process flow, but may also cause secondary accidents such as gas accumulation and floods.

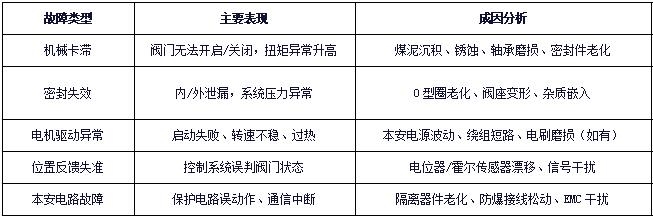

1、 Typical Failure Modes and Cause Analysis

2、 Fault diagnosis technology path

1. State monitoring based on multi-source sensing

Under intrinsic safety power consumption limitations, low-power sensors are preferred:

-Current/voltage waveform monitoring: Identify stuck or overloaded signals through transient characteristics of driving current;

-Micro vibration signal acquisition: using MEMS accelerometers to capture abnormal valve stem motion;

-Temperature monitoring: Infrared or thermistor detection for local overheating of the motor or valve body;

-Position feedback verification: Compare the command position with the actual feedback to determine the transmission chain fault.

Note: All sensors and signal conditioning circuits must pass intrinsic safety certification (such as Ex ia I Ma).

2. Signal processing and feature extraction

-Using wavelet transform or empirical mode decomposition (EMD) to remove strong underground noise interference;

-Extract time-domain (root mean square, kurtosis), frequency-domain (main frequency energy), and time-frequency domain features;

-Build a multi state feature library of "health sub-health fault".

3. Data driven diagnostic model

-Traditional methods: Support Vector Machines (SVM) and Hidden Markov Models (HMM) are suitable for small sample scenarios;

-Deep learning: Lightweight CNN or LSTM networks deployed on edge controllers to achieve real-time diagnosis on the end side;

-Transfer learning: utilizing ground simulation platform data for pre training to reduce dependence on underground annotation data.

3、 Predictive maintenance system architecture

Propose a three-level collaborative architecture of "end edge cloud":

1. End side (intrinsic safety valve body):

-Integrate low-power MCU and sensors to perform local feature extraction and primary diagnosis;

-Upload critical status data via intrinsic safety RS485/CAN bus.

2. Edge side (underground intrinsic safety gateway):

-Aggregate data from multiple ball valves and run a lightweight prediction model;

-Generate Remaining Useful Life (RUL) estimates and maintenance work order recommendations.

3. Cloud (Ground Monitoring Center):

-Build a digital twin model to visualize the health status of all valves in the mine;

-Optimize maintenance strategies based on equipment ledger, maintenance records, and environmental parameters.

-This architecture achieves a closed-loop of "perception diagnosis prediction decision" while ensuring intrinsic safety.

The fault diagnosis and predictive maintenance of intrinsically safe electric ball valves for mining are important supports for improving the intrinsic safety level of coal mines. By integrating low-power sensing, edge intelligence, and cloud platform collaboration, the transition from "passive maintenance" to "active prevention" can be achieved under strict intrinsic safety constraints.