-

E-mail

shenyanbo@kanomax.com.cn

-

Phone

18840065038

-

Address

No. 56-39 Huanghe North Street, Huanggu District, Shenyang City

Shenyang Jiaye Scientific Instrument Co., Ltd

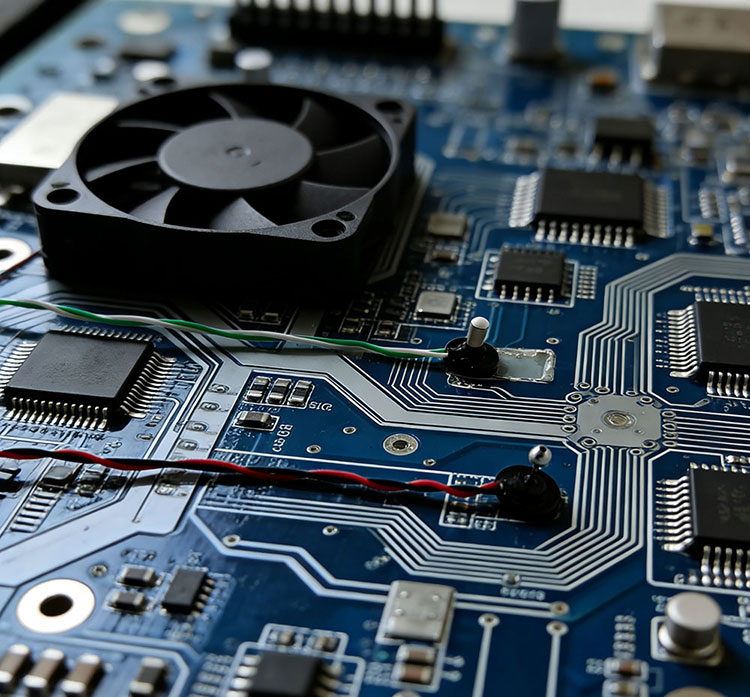

With the rapid improvement of electronic device performance and integration, the power density of circuit boards continues to increase, and thermal interactions have become more complex. The hidden risk of "overheating" may lead to the failure of precision circuit design and cause irreversible losses. Therefore, heat dissipation efficiency is the core factor in ensuring stable operation of equipment and extending its service life.

1、 Global synchronous monitoring

The limitation of traditional testing is that it often can only capture the temperature of individual "hotspots", but cannot answer systematic questions such as where the heat comes from, where the wind goes, whether the airflow is short circuited, and whether there are vortex blind spots. The multi-point environment testing system 1590 breaks this limitation and achieves real-time synchronous data acquisition in the core area of chips and power devices, airflow channels, critical paths, PCB board level, spatial microenvironment, etc. Engineers can visually observe the full dynamic process of heat generation, accumulation, migration and diffusion with airflow on the circuit board, and accurately locate each heat dissipation bottleneck.

2、 Precision sensing and flexible deployment

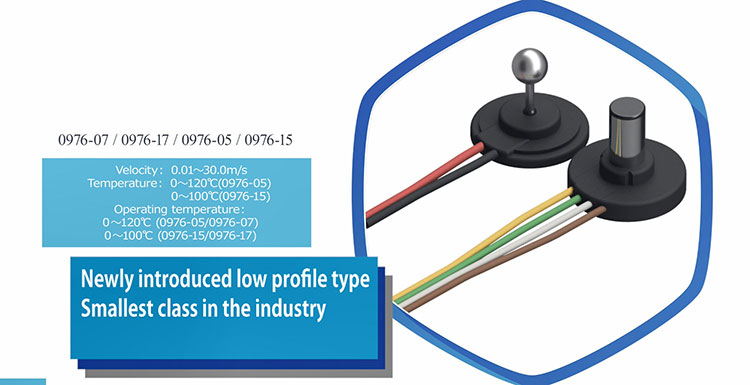

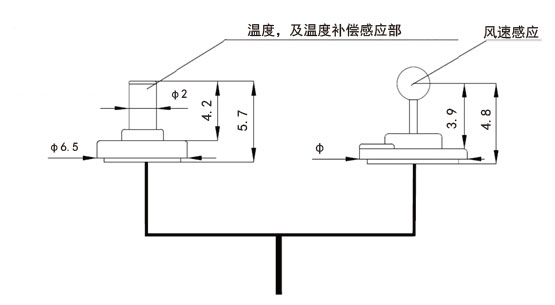

Multi point environmental testing system 1590 and candle holder wind speed and temperature probe 0976-07 haveexcellentPerformance and resilience architecture.

The probe adopts a miniaturized design, and its slender sensor head can easily extend into millimeter sized gaps for "undisturbed" measurement without significantly changing the original spatial structure and airflow state. At the same time, it is equipped with highly sensitive sensors that can accurately capture weak airflow at the 0.01m/s level (which is crucial for identifying airflow dead zones under natural convection or low-speed fans) and temperature fluctuations at the 0.1 ℃ level, ensuring the complete reliability of the data.

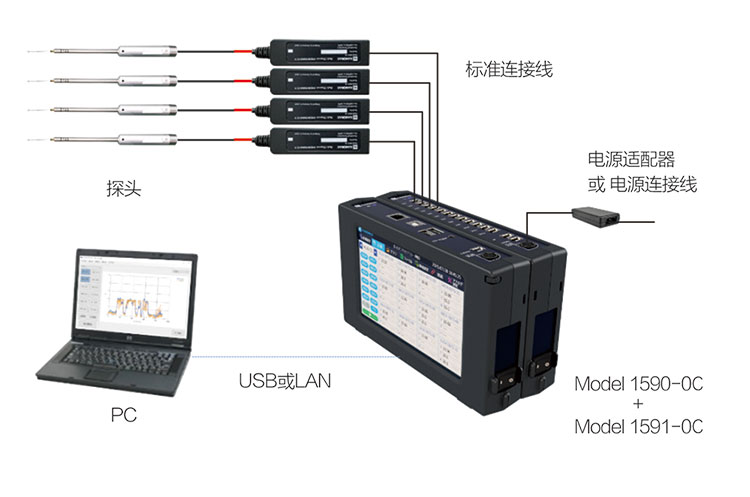

System 1590 itself is an open platform. Its modular design allows users to flexibly configure the required number of data acquisition channels based on the actual size and complexity of the tested circuit board. Whether it is an embedded industrial control board that is only the size of a palm, or a server motherboard that is several feet long and equipped with multiple processors and memory, a testing matrix that meets the requirements can be built by adding modules.

The 7-inch color touch screen host equipped in the system integrates parameter settings, real-time data, and images. Engineers can quickly complete the point selection and sampling frequency setting of all probes on the testing site, greatly improving debugging efficiency.

3、 From testing and validation to optimizing the closed-loop system

The multi-point environment testing system 1590 not only identifies problems, but also quantitatively compares the global temperature and wind data under different heat dissipation schemes (such as changing fan layout, adjusting fin density, and using different thermal conductive materials) during the design verification phase, providing a solid basis for design decisions and shortening the trial and error cycle.

The 1590 system can perform long-term aging and pressure testing, monitor the performance degradation trend of the cooling system and potential thermal runaway risks, and provide key data for predicting equipment life.

In fault diagnosis and analysis, when thermal related abnormalities occur in on-site equipment, test conditions can be reproduced and historical benchmark data can be compared to quickly locate the cause of the abnormality and optimize the overall system.

The combination testing of multi-point environmental testing system 1590 and candle type wind speed and temperature probe 0976-07 transforms the heat dissipation state of the circuit board from a fuzzy qualitative description to an accurate, correlated, and analyzable digital model, providing practical technical support for heat dissipation design and management.

Multi point environmental testing system 1590, a system body MODEL 1590-0C can simultaneously connect 12 testing modules, each of which can connect 12 probes with different functions. It can build a system with up to 144 channels for simultaneous testing of wind speed, temperature, and relative humidity, meeting the requirements of large-scale testing in large spaces.

15 different types of probes are interchangeable and compatible, with temperature compensation function for both directional and non directional probes. They have high testing accuracy and fast response time, and are equipped with the smallest probes in the industry, making it easy to install and test in specific spaces such as small spaces. They also have high-temperature probes that can withstand 120 ℃, enabling precise testing in high-temperature environments. Equipped with an analog output unit, the system can select current or voltage as needed to achieve analog output. The system body adopts a 7-inch color LCD touch screen.

KANOMAX Multi point Environmental Testing System 1590 can be applied to ECU heat management, motherboard heat evaluation, semiconductor device airflow management, data center environment management, cabin and radiator airflow testing, tunnel wind speed distribution testing, train cabin wind speed distribution, and wind speed testing analysis corresponding to smoke hoods.