-

E-mail

cubic-ry56@gasanalyzer.com.cn

-

Phone

18627990650

-

Address

No. 6 Fenghuangyuan Middle Road, Fenghuangyuan Industrial Park, Donghu New Technology Development Zone, Wuhan City, Hubei Province

Sifang Optoelectronics (Wuhan) Instrument Co., Ltd

1. Blast furnace gas: from a byproduct of ironmaking to a valuable energy source

Blast furnace ironmaking, as the main process of modern ironmaking, accounts for over 95% of the world's total pig iron production. This process uses iron ore, limestone, and coke as raw materials, which are layered and loaded into the blast furnace in a certain proportion; At the same time, oxygen enriched air heated by the hot blast furnace is blown into the furnace through the air inlet. In the furnace, the raw materials undergo a series of complex chemical reactions: coke burns with hot air in the tuyere area to produce CO2, which reacts with the hot coke to produce CO during the rising process. CO further reduces iron ore step by step to metallic iron, ultimately forming molten iron. At the same time, a large amount of blast furnace gas is generated by the reaction and discharged from the top of the furnace.

2. Real time monitoring: the "eyes" of optimizing processes and safety

Real time monitoring of the composition of blast furnace gas aims to optimize smelting processes and energy efficiency, prevent flammable and explosive risks, and ensure that pollution emissions meet standards.

3. Gas chromatography technology is inadequate

At present, online gas chromatography analysis technology is commonly used for blast furnace top gas analysis. Its working principle is to use a chromatographic column for gas separation, and then use a TCD thermal conductivity detector for component analysis.

However, online gas chromatography analyzers still have several limitations in practical applications, such as long analysis cycles, complex operations, and high maintenance costs.

(1) Analyze the existence of 'time delay'

Although a single analysis is fast, there is a certain lag time (usually a few minutes) in the entire process from sampling, sample transfer, preprocessing to completing the analysis, which cannot achieve real-time monitoring at the second level and has a slow response speed to sudden component fluctuations.

(2) Complex operation and high technical threshold

The online analysis system requires professional operators to maintain, including chromatographic column aging, carrier gas management, regular calibration, etc. The technical threshold is high and requires certain professional knowledge and experience.

(3) Large maintenance workload and high cost

Chromatography requires long-distance sample transportation, complex pretreatment systems, and large on-site maintenance of various consumables (carrier gases, chromatography columns, etc.). The lifespan of chromatographic columns (core consumables) is usually 6-12 months (affected by sample contamination), and the replacement cost is about 10000-30000 yuan per column; The detector needs to be cleaned regularly, and the carrier gas cylinder needs to be replaced frequently, resulting in high long-term maintenance costs.

4. Breakthrough in Laser Raman Spectroscopy Technology

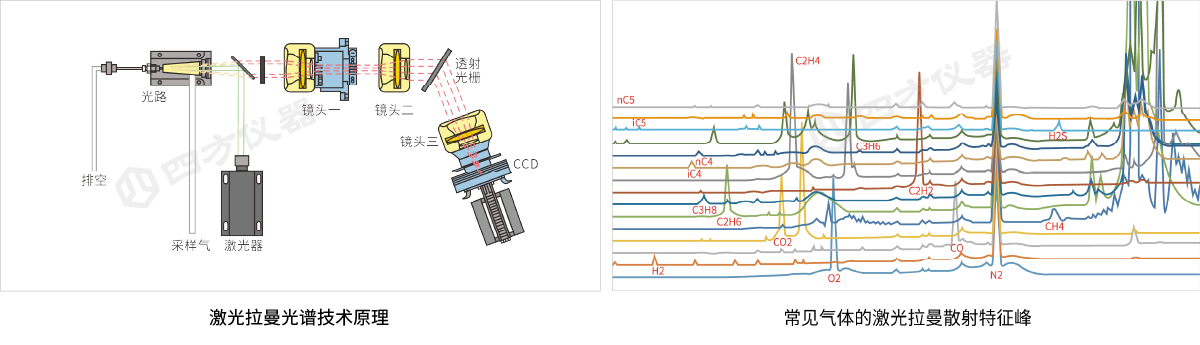

Laser Raman spectroscopy (LRD) is a spectroscopic gas analysis technique based on gas Raman scattering. Using a laser with high beam quality to emit laser light of a specific wavelength, it is focused in a gas chamber through an achromatic lens, and at the focal position, the laser collides with gas molecules to produce Raman scattering. The Raman scattering wavelengths corresponding to different gases are different (referred to as the Raman characteristic peaks of gases). The intensity of Raman peaks is directly proportional to the gas concentration value. By analyzing the position and intensity of gas Raman characteristic peaks through spectroscopy, simultaneous measurement of multiple components can be achieved. In addition, due to the very short excitation and collection time of Raman scattering spectroscopy, it has a faster response time compared to chromatography.

Comparing the three major advantages of gas chromatography based on LRD principle:

(1) Fast response speed:Almost real-time measurement, with a response time of about 10 seconds.

(2) Simple configuration and easy operation:Composed of pre-processing, probe, and analyzer mainframe, with intelligent operation.

(3) Low maintenance workload:No consumables such as chromatography columns and carrier gases are required, and the on-site maintenance volume is close to zero.

5. Four party instrument LRGA series: domestic independent innovation

To solve the monitoring problem of easy blockage and difficult long-term stable operation of the blast furnace top gas analysis system under harsh conditions such as high temperature, high pressure, high dust, and humidity, Sifang Instrument has developed an online analysis system based on laser Raman spectroscopy technology. Combined with efficient preprocessing, it achieves continuous real-time monitoring of the gas at the outlet of the dust collector, helping technicians accurately grasp the furnace conditions, optimize reaction processes, and obtain better technical and economic indicators, providing reliable guidance for blast furnace production.

Since 2012, Sifang Instrument has relied on its parent company (Sifang Optoelectronics Co., Ltd.)'s core gas sensing technology platform to lead the national major scientific instrument and equipment development project "Research and Application of Laser Raman Spectroscopy Gas Analysis Instruments". In response to industry technical challenges such as weak characteristic signals in laser Raman spectroscopy, Sifang Instrument has been deeply cultivating for more than ten years, continuously researching laser Raman spectroscopy gas analysis technology, and finally successfully developing a commercial product with independent intellectual property rights - the LRGA series laser Raman spectroscopy gas analyzer, which fills the technical gap in related fields in China. At the same time, with its profound technical foundation and product performance, Sifang Instrument has emerged in the industry, actively participating in the formulation of industry standards and promoting industrial upgrading.