-

E-mail

wangyan@vega.com

- Phone

-

Address

Room 218, Building 9, Jiaxing Advanced Manufacturing Industrial Base International Innovation Park (Phase II), No. 1188 Fenghua Road, Economic and Technological Development Zone, Jiaxing City, Zhejiang Province

Weige (China) Instrument Co., Ltd

Wood powder is the main raw material for producing particleboard. Coarse shavings are used to make the core layer of the board, while fine wood powder is used to make the surface layer. In the production process of particle board manufacturer D&R Henderson, very dry lightweight wood powder is stored in a21 meter high siloIn the middle. However, this poses a challenge for measurement.

1

Why is it difficult to measure wood powder?

Wood powderLightweight, soft texture, low moisture contentTraditional level measurement methods are ineffective. Sheeshendra Deo, the electrical manager of D&R Henderson, stated that finding a suitable level gauge is a continuous process of trial and error.

The company first attemptedUltrasonic level gaugeIt detects the level of material in the silo by emitting sound waves. butFluffy wood powder absorbs sound wavesThis leads to very unreliable measurement readings. In addition, dust in the air can also affect the ultrasonic level gauge, further weakening the signal strength of the instrument.

We tried many types of level gauges, but none of them worked, "he said." Our product has a very low moisture content. These level gauges usually require a certain level of humidity to measure the accurate level

Wood powder (schematic diagram)

Jim Curnow is the Business Development Manager of VEGA's Australian subsidiary, and he explained that, “The dielectric constant of wood powder is too low, making it almost invisible for a typical level gauge.”

2

Encountering VEGA measurement solutions

The company has tried many types of instruments, but none of the products can accurately detect this material. Another potential solution is a weighing sensor, but its price is daunting and its accuracy is also affected by wind and other factors.

Accurate measurement of this silo is crucial for D&R Henderson Company. If you don't know how much wood powder is still in the silo during production, it may lead to a loss of productivity. At the same time, wood powder also needs to serve as a supplementary fuel for natural gas in the burner of the particle dryer, so inaccurate measurement results can lead to a sharp increase in natural gas costs.

VEGAPULS radar level gauge on site

In the end, the manufacturer decided to try out the new VEGA modelVEGAPULS radar level gaugeWood powder is one of the media that VEGA promotes for accurate measurement.

3

The measurement secret of VEGA level gauge

Curnow introduced that,VEGA's 80 GHz radar level gauge is different from other instruments tried by the customerHaving far greater capabilitiesdynamic rangeThat is to say, it is much more sensitive than other instruments and can accept and process weak signals reflected by such media.

The dynamic range of VEGAPULS radar level gauge reached 120 decibels, while other products tried by the customer were around 85 decibels. Decibel is a logarithmic scale unit, so increasing from 85 to 120 is not just a 25% increase, but also meansSensitivity increased by 1000 timesTherefore, when facing low dielectric constant media, the quality of the echo obtained by the instrument is significantly improved, and it can basically achieveNot affected by dust and adhesion.

——Curnow

Another design feature that helps the instrument prevent dust and adhesive interference is that this level gauge does not use a horn antenna. Traditional radar instruments generally use horn shaped antennas to focus radar waves in the correct direction. However, this VEGAPULS radar level gauge chooses to use a lens antenna instead of a horn mouth,Eliminating the hardware structure that is prone to scale buildup in the medium.

4

What are the advantages of VEGA instruments?

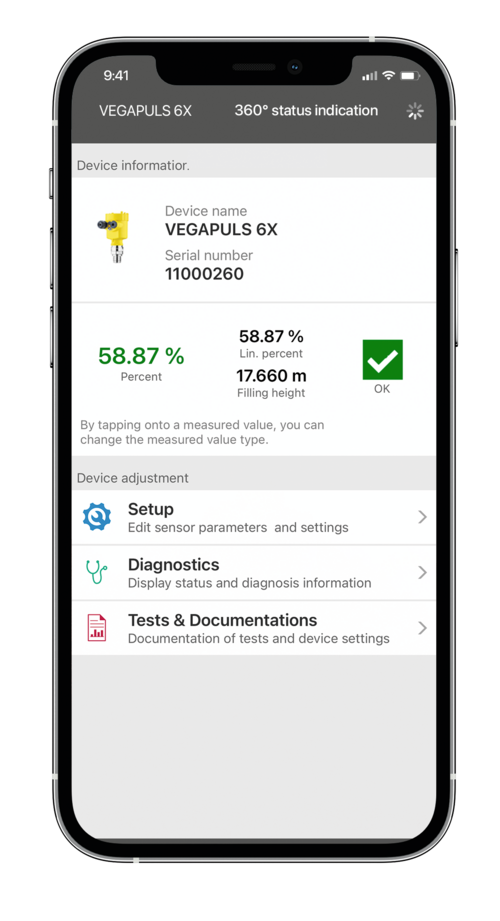

VEGA instruments do not require maintenance and can be put into operation after installation. VEGAPULS level gauge withBluetooth functionTherefore, employees can set and debug it on the ground with their mobile phones, and if parameters need to be changed, they no longer need to climb the 21 meter high ladder with their computers.

Deo said that VEGA specifically took samples of wood powder from the site to test whether the instrument could measure normally. They took many samples, and after seeing the test results, we were very confident in the performance of the instruments, "he said." After that, we started replacing other instruments on site with VEGA's. Now, we have installed nearly 10 level gauges. ”

Wood powder is dry and fluffy, which is difficult to measure with ordinary level gauges

Curnow said that the continuity of VEGA products is the key to the company's success.New VEGAPULS radar level gaugeBy integrating the advantages of all past radar level products, it is possible toDealing with almost all applications, measuring any medium.

About VEGA

VEGA is a manufacturer of level, limit, pressure, and density measuring instruments, and provides equipment and software for integrating instruments into process control systems. VEGA has over 2600 employees and has provided solutions to measurement challenges in various applications for over 60 years, including chemical and pharmaceutical equipment, food processing, drinking water supply, sewage treatment, landfill, mining, power generation, drilling platforms, ships, aviation, and more.