-

E-mail

wangyan@vega.com

- Phone

-

Address

Room 218, Building 9, Jiaxing Advanced Manufacturing Industrial Base International Innovation Park (Phase II), No. 1188 Fenghua Road, Economic and Technological Development Zone, Jiaxing City, Zhejiang Province

Weige (China) Instrument Co., Ltd

What is aerated concrete?

In the production process of aerated concrete,Level measurement of raw material warehouseIt is a key link to ensure the continuous and stable operation of production. Traditional heavy hammer level gauges are unable to meet the needs of modern production due to issues such as low measurement accuracy, susceptibility to material characteristics, and high maintenance costs. In recent years, radar level gauges have been widely used in the level measurement of aerated concrete raw material warehouses due to their advantages of non-contact measurement, high precision, and high reliability.

Heavy hammer level gaugeMeasuring material height through the lifting and lowering of a mechanical heavy hammer has a simple working principle, but it has the following limitations:

Easily affected by material characteristics

For viscous, clumping, and corrosive materials, heavy hammers are prone to jamming or damage, affecting measurement stability.

high maintenance cost

Heavy hammers and steel wire ropes require regular maintenance and replacement, which increases maintenance costs and workload.

Radar level gaugeUsing microwave technology for non-contact measurement has the following technical advantages:

high precision

By using high-frequency microwave signals, the measurement accuracy can reach millimeter level, meeting the requirements of high-precision measurement.

high reliability

No mechanical moving parts, strong anti-interference ability, stable and reliable operation, low maintenance cost.

VEGA radar level gauge

installation site

A domestic aerated concrete production enterprise's raw material warehouse originally used a heavy hammer level gauge, which had problems such as large measurement errors and frequent maintenance. To address these issues, the company has decided to upgrade and transform the radar level gauge.

Based on the actual situation of the raw material warehouse, VEGA measurement engineers have selected for the userHigh frequency radar level gaugeInstalled on the top of the raw material warehouse. The radar level gauge emits high-frequency microwave signals, which are reflected back upon encountering the surface of the material. By calculating the time difference between the transmitted and received signals, the level height can be obtained.

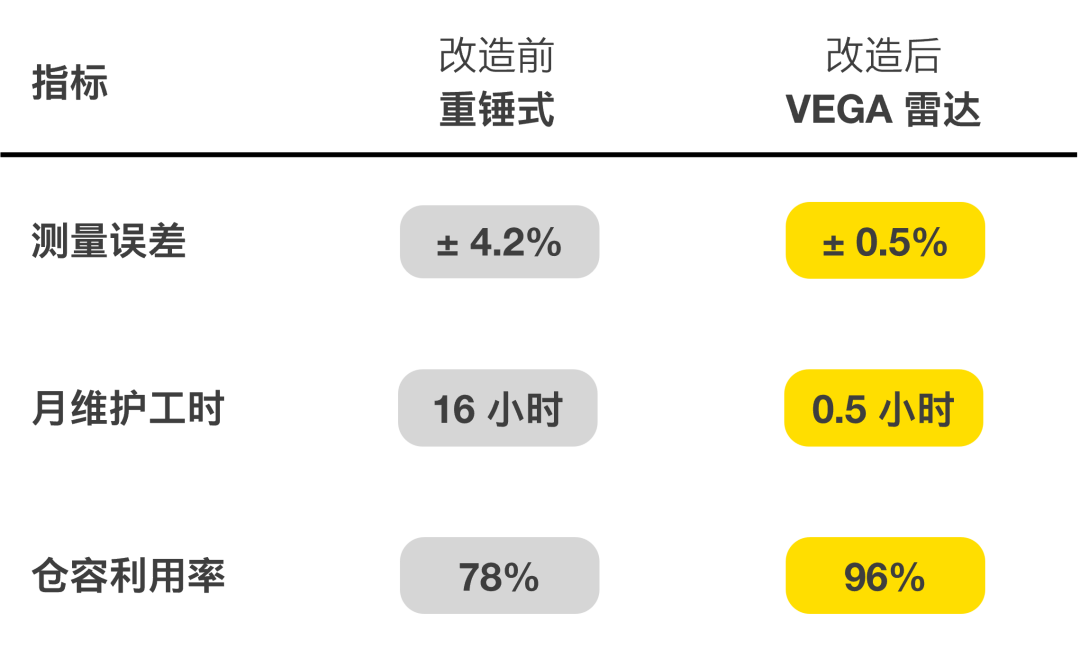

After the renovation, the level measurement effect of the enterprise's raw material warehouse has been significantly improved:

The application of VEGA radar level gauge in the raw material warehouse of aerated concrete effectively solves the problems of traditional heavy hammer level gauges, achieves technological upgrades in level measurement, improves production efficiency and product quality, and brings significant economic benefits to users.

About VEGA

VEGA is a global manufacturer of level, limit, pressure, and density measuring instruments, and provides equipment and software for integrating instruments into process control systems. VEGA has over 2600 employees worldwide and has provided solutions to measurement challenges in various applications for over 60 years, including chemical and pharmaceutical equipment, food processing, drinking water supply, sewage treatment, landfill, mining, power generation, drilling platforms, ships, aviation, and more.

Last Article: 10 things you may not know about VEGA

Next Article: VEGA Sanitary Measurement Solution