-

E-mail

2495634026@qq.com

-

Phone

15389011663

-

Address

5th Floor, F-2B, No. 2 Guangde Road, Xigao New Area, Xi'an City, Shaanxi Province

Xi'an Dinghua Electronics Co., Ltd

user

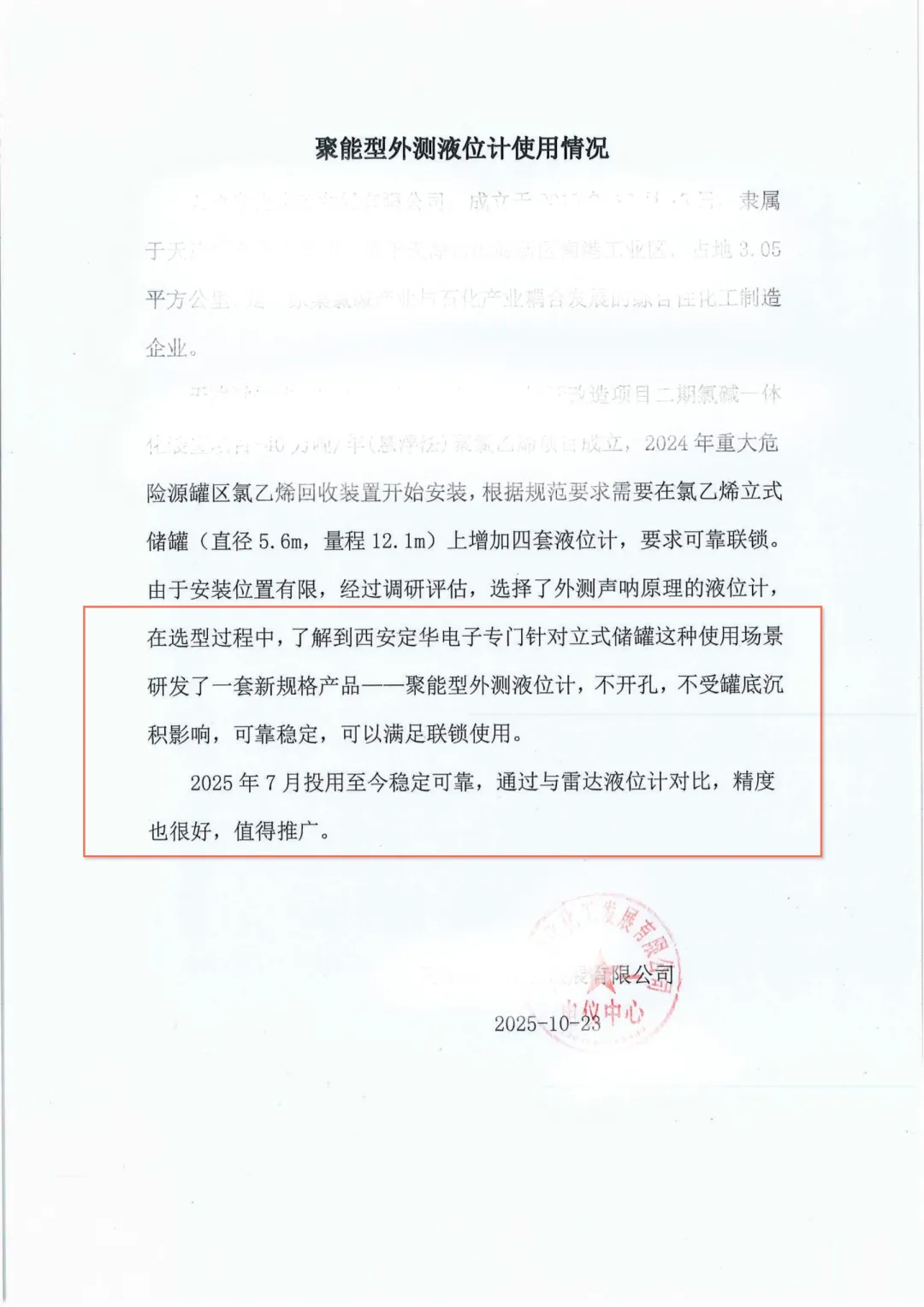

Tianjin Chemical Co., Ltd., covering an area of 3.05 square kilometers, is a comprehensive chemical manufacturing enterprise that integrates the development of chlor alkali industry and petrochemical industry.

application

Recycling VCM monomer tank (diameter 5.6m, range 12.1m).

challenge

1. Medium characteristics: high-risk, variable, impure

Intrinsic safety risk: Vinyl chloride monomer is flammable, explosive, and toxic, and any leakage may cause catastrophic consequences.

Aggregation and scaling: The recovered crude monomers contain residual initiators, dispersants, and tiny PVC particles, which will continue to polymerize in the liquid phase, forming polymers ("fish eyes") that adhere to the inner walls of the container and any invading surfaces.

Impurity complexity: Impurities may be corrosive or crystallize under different temperatures and pressures.

2. Process: dynamic, intermittent, difficult to maintain

Sausage jar "operating mode: As a buffer and mixing jar, its liquid level, pressure, and temperature fluctuate frequently, and the working conditions are unstable.

Intermittent operation: The start stop cycle accelerates the generation and attachment of polymers.

Difficulty in tank cleaning: Regular cleaning requires production stoppage, replacement, manual tank cleaning, short instrument maintenance window, and high cost.

Dinghua Solution

Dinghua Electronics has specially developed a new product - the energy gathering type external liquid level gauge, which is not afraid of complex working conditions, suitable for vertical tanks, with a signal improvement of 20-50 times, "zero blind spots", and more stable and reliable.

Image source: On site instrument diagram Source: Dinghua engineer

Image source: On site instrument diagram Source: Dinghua engineer

This product is mainly designed for harsh working conditions such as vertical storage tanks. Traditional contact measuring instruments often perform poorly for PVC recycling tanks with coarse monomers due to blockage, adhesion, and difficult maintenance. The energy gathering type external liquid level gauge can physically avoid most of the challenges brought by the medium itself. Compared with traditional external liquid level instruments, the measurement signal is significantly improved, which can effectively overcome tank bottom sedimentation, reduce measurement blind spots, and significantly improve stability and accuracy.

Breakthrough 1: Achieve 'intrinsic safety' and zero leakage risk

Problem solving: Eliminate the risk of leakage caused by instruments.

Working Principle:

1) Installation outside the tank: The instrument probe and host are installed on the outer wall of the tank without damaging the integrity of the container.

2) Physical isolation: The measurement system is isolated from the hazardous medium by a thick tank wall. Eliminating leakage paths structurally is a high-level intrinsic safety.

Breakthrough 2: Ignoring "adhesion and pollution", anti blocking and anti sticking

Problem solving: Solve the problems of polymer and impurity adhesion, scaling, and instrument blockage.

Working Principle:

1)Non contact measurement: Based on sonar echo technology, sound waves penetrate the tank wall for measurement. Instrument sensing unit (probe) not availableContact medium.

2) Principle advantage: No matter how viscous, polymerized, or crystallized the medium is, it will not contaminate or damage the probe. It realizes the saying 'you build your own dirt, I measure my position'.

Breakthrough Three: Penetrating through Thick Walls and Interference, Stable and Reliable

Problem solving: Overcome signal interference caused by pressure vessel wall thickness, internal components (baffles, stirrers), and liquid level fluctuations.

Working Principle:

1) The core of "energy gathering" technology: through specially designed probes and algorithms, the sound wave energy is highly focused to form a stronger and more directional "sound wave energy beam".

2) Strong penetration: High energy enables it to effectively penetrate thicker container walls and bring back clear liquid level signals.

3) Anti interference: The focused beam and intelligent signal processing can accurately distinguish between the real liquid level echo and the interference echo generated by internal components, lock the real liquid level in complex sound fields, and ensure long-term stable data without jumping.

Breakthrough 4: Support "online operation and maintenance" to reduce costs and increase efficiency

Problem solving: Achieving non-stop installation and maintenance, avoiding costly shutdown losses and complex tank cleaning safety operations.

Working Principle:

1) Online installation and debugging: All work is carried out outside the tank and can be completed without stopping the entire production line and filling the tank with hazardous media.

2) Convenient maintenance: Calibration, inspection, and replacement are all operated outside the tank, without the need for process treatment, hot work, or confined space, greatly reducing maintenance risks, time, and costs.

summary

Since its launch, the energy gathering type external liquid level gauge has been stable and reliable. Through comparative observation with the original imported radar level gauge of the enterprise, its measurement data is accurate, highly consistent, and meets the strict requirements of the safety interlock system for measurement accuracy. It has significant promotion and application value.

Image source: User feedback report source: Dinghua engineer

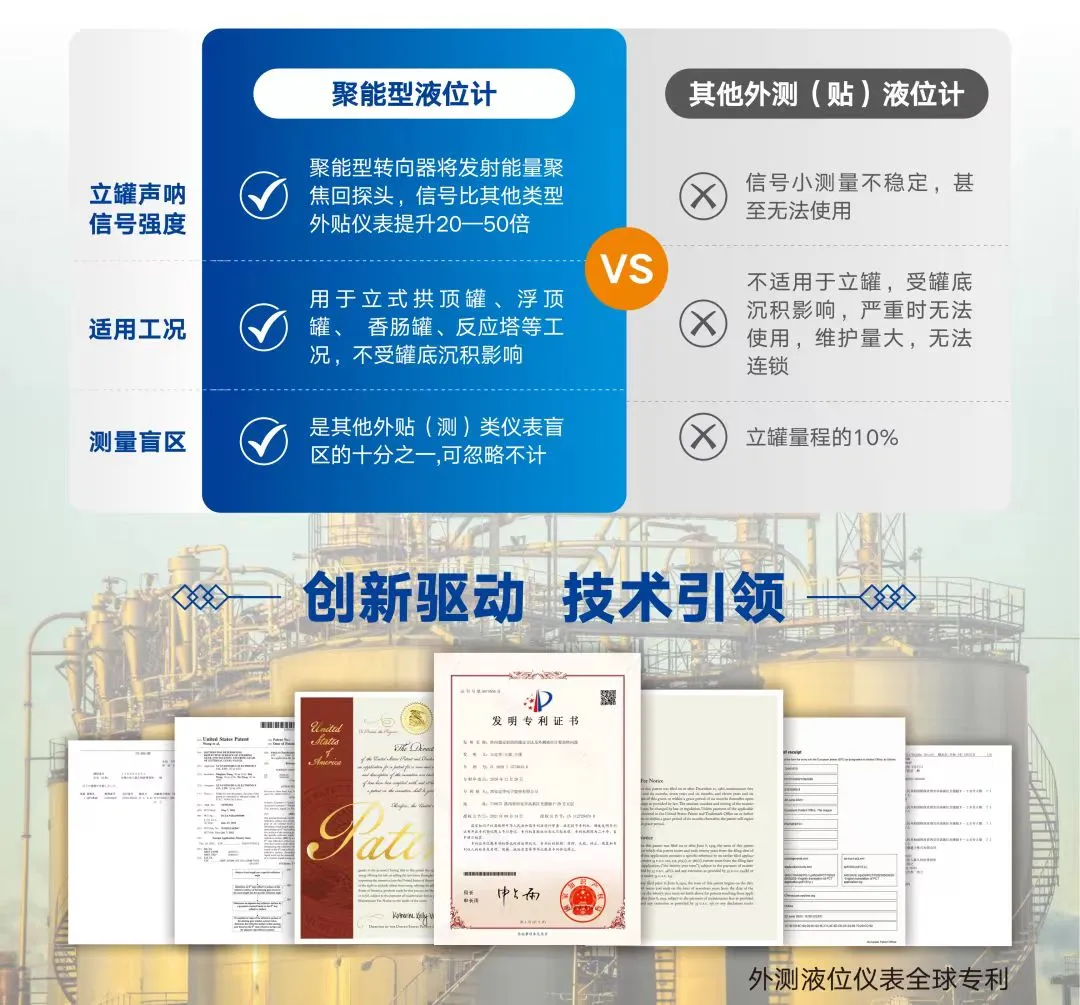

Advantages of Energy Gathering External Liquid Level Gauge

1. Fearless of complex working conditions, suitable for vertical tanks

Used for working conditions such as vertical dome roof tanks, floating roof tanks, sausage tanks, reaction towers, etc., it can effectively overcome interference factors such as self aggregation deposition at the bottom of the tank. Even in harsh media environments such as high temperature, high pressure, strong corrosion, high viscosity, and high toxicity, it can work stably and has a wide range of applications.

2. Signal increase by 20-50 times

The innovative energy gathering sonar signal steering device can focus the vast majority of the emitted energy back onto the probe. Practical application data shows that it can increase energy by at least 20-50 times, ensuring reliable and stable measurement.

3. "Zero blind spots"

Using Xi'an Dinghua Electronics' "small blind spot technology" and energy gathering technology for blind spot migration, achieve blind spot free measurement.

4. More stable and reliable

It can measure liquids with higher viscosity and is not affected by severe sedimentation at the bottom of the tank, effectively reducing the impact of bubbles and multiple interfering devices inside the container on the measurement.