-

E-mail

18206139191@163.com

-

Phone

18206139191

-

Address

2505, Building 2, Jitian International Plaza, 999 Bailu South Road, Kunshan Development Zone

Suzhou Yujingheng Automation Equipment Co., Ltd

3-ton small electronic weighing platform with a height of 1.2 times 1.5 meters

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

3-ton small electronic weighing platform with a height of 1.2 times 1.5 meters

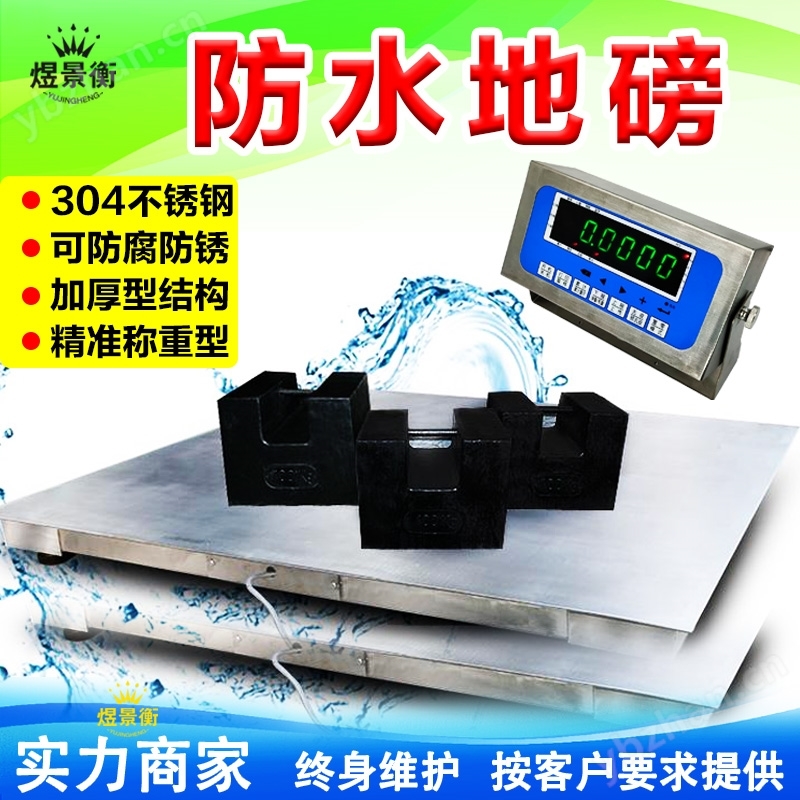

Analysis of Basic Parameters of 2-ton Small Electronic Weighing Scale

A 2-ton small electronic weighing scale (with a table size of 1.2 meters by 1.5 meters) is a common small and medium-sized weighing equipment, mainly used for weighing goods in warehouses, workshops, logistics and other scenarios. The core parameters need to be comprehensively evaluated based on load-bearing capacity, tabletop size, and usage scenarios:

Suzhou Yujingheng brand YJH-T7 YJH-A7 YJH-B7 YJH-T YJH-A YJH-B industrial series recommendation

Rated weight: 2 tons (i.e. maximum weight of 2000kg), usually equipped with overload protection function (usually triggered at 120% of the rated value, i.e. 2400kg).

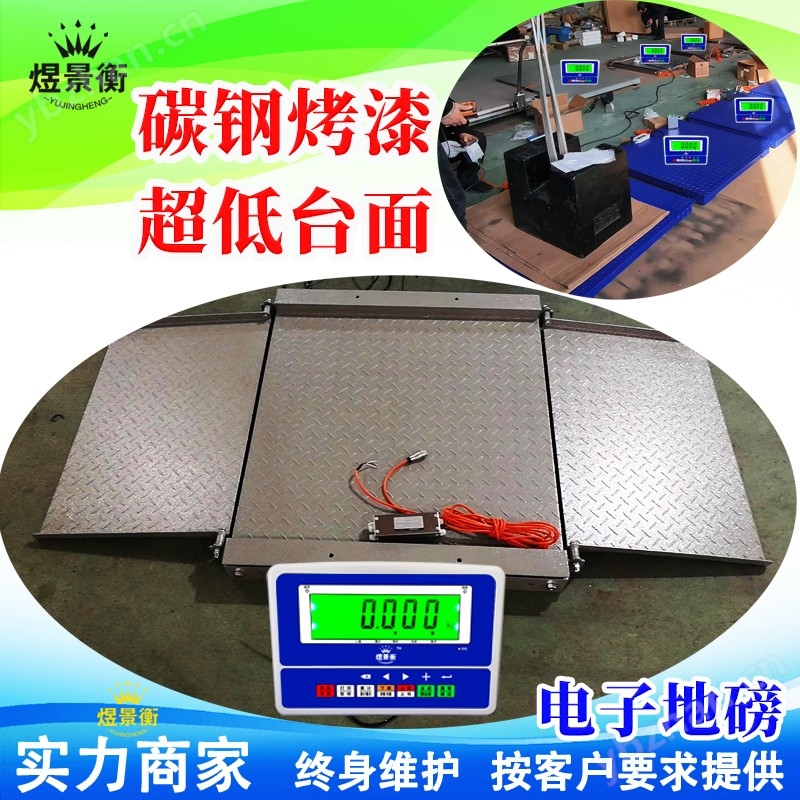

Table size: 1.2m (width) x 1.5m (length), suitable for small and medium-sized goods (such as cardboard boxes, pallets, and small equipment). The table material is mostly Q235 carbon steel (anti slip pattern design), with a thickness of about 3-5mm. The spacing between load-bearing beams is reasonably distributed to ensure structural stability.

Applicable scenarios and limitations

3-ton small electronic weighing platform with a height of 1.2 times 1.5 meters

Applicable scenarios:

Weighing of small and medium-sized goods: such as express packages, raw material packages (20-50kg/bag), small mechanical parts, etc. The table size can accommodate 1-2 standard pallets (such as 1m x 1.2m pallets).

Space limited environment: The 1.2 × 1.5m countertop covers an area of only 1.8 square meters and is suitable for installation in small areas such as workshops and warehouse corners. It supports direct placement on the ground or installation in shallow foundation pits (reducing the height of the countertop for easy loading and unloading of carts).

Medium precision requirements scenario: The general division value is 0.1kg or 0.2kg (i.e. the minimum reading is 0.1kg), which meets the needs of ordinary industrial weighing (such as batching, inbound and outbound weighing), but is not suitable for high-precision laboratory scenarios.

局限性:

Large goods cannot be weighed, such as long strip goods (such as pipes and boxes) with a size exceeding 1.5m or single volume goods weighing nearly 2 tons (which may exceed the load-bearing distribution range of the table and cause measurement errors).

Weak dynamic weighing capability: Without buffering design, it is prone to impact errors when quickly placing goods, and manual zeroing is required before static weighing.

Precautions for selection and use

Key points for purchasing:

Load bearing matching: Confirm the maximum single weight (≤ 2 tons) and size (length and width ≤ 1.5m × 1.2m) of daily weighing goods to avoid "small horses pulling large carts" or table waste.

Accuracy level: Select the division value according to the requirements. For example, chemical ingredients require a precision of 0.1kg, while ordinary storage can choose 0.2kg.

Function configuration: The basic version supports weighing display, while the advanced version can come with RS485/USB interface (for connecting to a computer to record data), printing function (for weighing orders), or explosion-proof design (for special industries).

Usage and maintenance:

Stable placement: During installation, it is necessary to level the foundation screws to avoid weighing deviation caused by tilting the ground.

Regular calibration: It is recommended to calibrate with standard weights (such as 1-ton weights) every six months to ensure accuracy.

Avoid overloading and impact: Forklifts are prohibited from directly crushing the countertop, and goods should be handled with care to prevent sensor damage.

Example application

A small food processing factory uses this specification of weighing scale to weigh flour raw materials, with each bag of flour weighing 25kg and weighing 40 bags each time (a total of 1000kg). The table can hold two trays of 20 bags at the same time, and the storage data is automatically recorded through the connected ERP system after weighing, improving efficiency.