-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

AI algorithm fully automatic image measuring instrument

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Novator series of instruments in ChinaAI algorithm fully automatic image measuring instrumentIt can achieve precise measurement of surface dimensions, contours, angles and positions, form and position tolerances, 3D spatial morphology and dimensional structures of various complex parts. Its AI automatic edge finding technology can quickly and accurately identify target features, making the measurement process intelligent and unmanned.

1、 Product Features

1. Full scene measurement: covering various requirements such as surface size, contour, angle, and positional tolerance, adapting to various parts such as connectors, molds, medical devices, etc., one device can handle multiple scenes.

2. Flexible adaptation: replaceable RGB light source+six ring eight zone lighting, capable of dealing with complex workpiece surfaces of different colors and materials. The independent lifting and lowering of the surface light design makes observation clearer.

3. Convenient operation: 24 inch high-definition display+integrated interface, beginners can get started in 1 hour, equipped with lens anti-collision and large format navigation camera, safe and worry free operation.

4. Diversified output: Supports importing and exporting Excel, Word, and AutoCAD files, can generate SPC analysis reports and Q-DAS transmission, making data traceability and quality control easier.

5. High precision+high stability, reliable and undisputed data

The algorithm has been certified by the PTB German Federal Institute of Physical Technology, reducing the proportion of dimensions with repeatability greater than 0.02mm by 81%. The consistency of measurement data from different operators far exceeds manual measurement, eliminating human errors and providing accurate data support for product quality control, helping enterprises improve product qualification rates.

6. Convenient operation+efficient programming, reducing the threshold for use

Support 3D offline programming, import 3D data to edit measurement programs in advance without occupying device standby time. The interface is intuitive and easy to operate, paired with practical tools such as scanning to extract edges, rapid measurement of R-angle, and batch tolerance setting. Even beginners can quickly get started, reducing reliance on professional operators.

2、 Core Highlights

1. The measurement time for a single workpiece has been reduced from the traditional 131 seconds to 28 seconds, directly increasing efficiency by 4.5 times, making batch measurement more efficient.

2. Supports aerial photography mode and 3D offline programming, increasing measurement efficiency by 5-10 times without occupying device standby time, and increasing device utilization by 60%.

3. The algorithm has been certified by the PTB German Federal Institute of Physical Technology, with an X/Y axis detection accuracy of (1.6+L/250) μ m and a Z-axis repeatability accuracy of ± 1 μ m.

The proportion of dimensions with repeatability greater than 0.02mm decreased by 81%, and the consistency of measurement data from different operators far exceeded manual measurement, with human error approaching zero.

The measurement accuracy of 5.3D scanning imaging reaches ± 0.1% F.S., accurately capturing the spatial morphology and dimensional structure of complex parts.

3、 AI automatic edge finding technology

1. The AI model training interface is simple, the algorithm is powerful, the training ability is strong, and the training data is intuitive.

2. AI measurement software can store images while measuring, continuously optimize and iterate AI models, and achieve high efficiency.

3. It can solve traditional measurement pain points such as blurred boundaries, multiple boundaries, excessive burrs, and excessive edge interference.

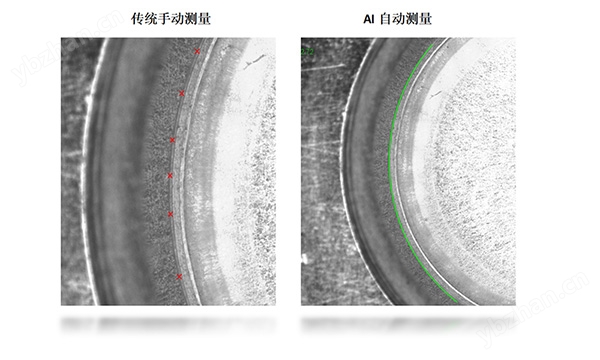

Compared to traditional manual measurement, Zhongtu Intelligent Unmanned AI Image Measuring Instrument has high efficiency and good repeatability.

4、 Application Cases of AI Measurement

1. When measuring the edge features of battery back covers in the new energy industry, due to the small difference in edge steps, there are multiple layers of boundary interference and low contrast in the imaging. Automatic batch measurement cannot automatically capture the target edge, so manual measurement is necessary. Zhongtu AI measurement can eliminate multi-layer boundary interference, automatically recognize target edges even with low contrast, improve measurement efficiency by 4.5 times, and eliminate human errors, resulting in more stable measurement data.

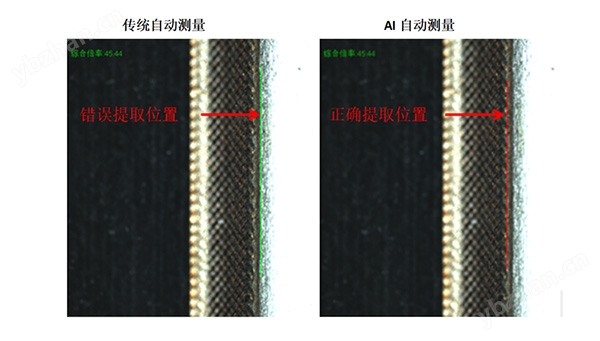

2. When measuring the edge line of the frame in the 3C industry mobile phone, due to the irregularity and interference of the boundary, traditional automatic measurement is prone to deviation and can only be manually measured. Even if there are irregular and interfering boundaries, the automatic measurement of Zhongtu AI can eliminate interference and automatically extract the correct position, further improving measurement efficiency.

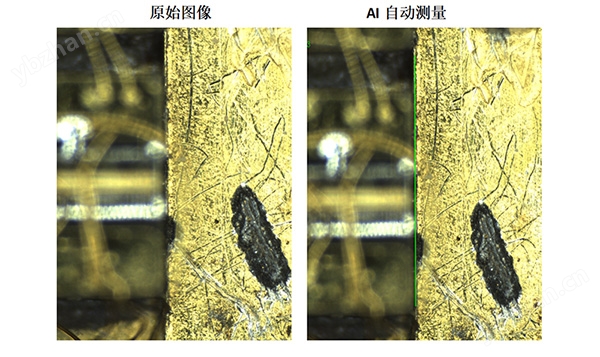

3. The metal edge boundary is blurry, with too many burrs and uneven curvature. AI measurement can automatically filter out burr interference and accurately extract the boundary.

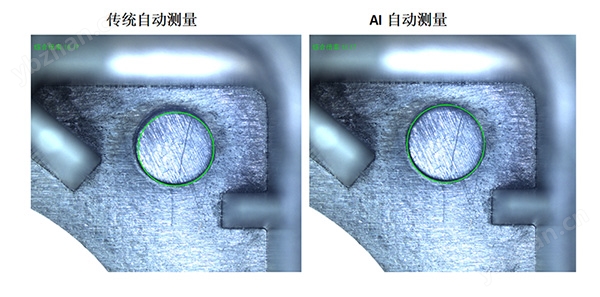

4. The cylindrical features on black plastic parts have different shapes and unclear edge contours, and traditional automatic measurement is prone to deviation, while AI extraction is precise and stable.

5. Plastic sheet boundaries have many interferences and cannot be automatically extracted. Manual measurement is laborious and labor-intensive, while AI measurement can accurately eliminate interference on the boundaries and extract the correct position.

The product parameters will be continuously optimized based on technological iterations, so the relevant content in this product information may be updated or modified at any time according to the actual situation without further notice. We apologize for any inconvenience caused.

Novator seriesAI algorithm fully automatic image measuring instrumentNot only measurement tools, but also strategic partners for enterprise automation upgrading and enhancing core competitiveness. Book a demo now and get free scene adaptation solutions and measurement efficiency evaluation reports, allowing data to witness your production upgrade!