-

E-mail

xaslck@163.com

-

Phone

18802933690,18829593940

-

Address

Xi'an High tech Zone New Industrial Park

Xi'an Sanlian Measurement and Control Technology Co., Ltd

Airflow measurement device

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

For thermal power generation enterprises, due to the measurement environment of desulfurization flue gas containing dust, slurry, corrosiveness, large cross-sectional area of flue gas, short length of straight pipe section, there are problems that cannot meet the measurement point specification requirements. Traditional measuring devices are prone to clogging, corrosion, and turbulence, making it difficult to ensure measurement accuracy and stability. They are also prone to operational failures, and data transmission rates and efficiency cannot meet national regulatory requirements. Therefore, independent research and innovation of flue gas velocity (flow) measurement technology is of great significance for national energy conservation and emission reduction, continuous improvement of atmospheric environmental quality, and the lawful collection of pollutant discharge taxes.

Xi'an Sanlian Measurement and Control specializes in manufacturing air flow measurement flow meters for nearly 20 years, providing a variety of intelligent air flow measurement devices with optimized structures, solving the problem of insufficient straight pipe sections, convenient installation through insertion, ultra-low pressure loss through insertion, large pipe diameter size, low flow rate, high dust content, maintenance free, and multiple measurement points. The company provides multi-point and multi throat flow meters, multi-point matrix flue gas air flow measurement devices, Velbar flow meters, delta bar flow meters, flat bar flow meters, plug-in double Venturi flow meters and other products, including multi throat flow measurement and matrix boostingAirflow measurement deviceThe plug-in multi section and Delta Bar have conducted multiple sets of experimental data with wind tunnel laboratories for many years, and have provided technical support and key project flow guidance to more than 30 power companies, waste incineration, desulfurization and denitrification, photovoltaics, air conditioning and other scientific research projects. The company's air volume measurement devices have been used on site for more than 45000 units.

The Xi'an Sanlian Measurement and Control Technology Team has tackled relevant challenges and conducted in-depth research on key issues such as the inability of conventional technologies to meet the actual measurement environment requirements on site, insufficient accuracy and stability. They have manufactured multi-point acceleration matrix array multi-point measurement technology and products. Fundamentally solving the technical difficulties in the national technical specifications for continuous monitoring of flue gas emissions from fixed pollution sources, and providing tax basis for environmental protection tax laws, effectively improving the technical level of continuous monitoring of flue gas emissions from fixed pollution sources. The successful research and development of this product depends on the unremitting efforts of the project team, as well as the powerful pneumatic laboratory and State Key Laboratory of aerodynamics

The design features and advantages of each product are as follows:

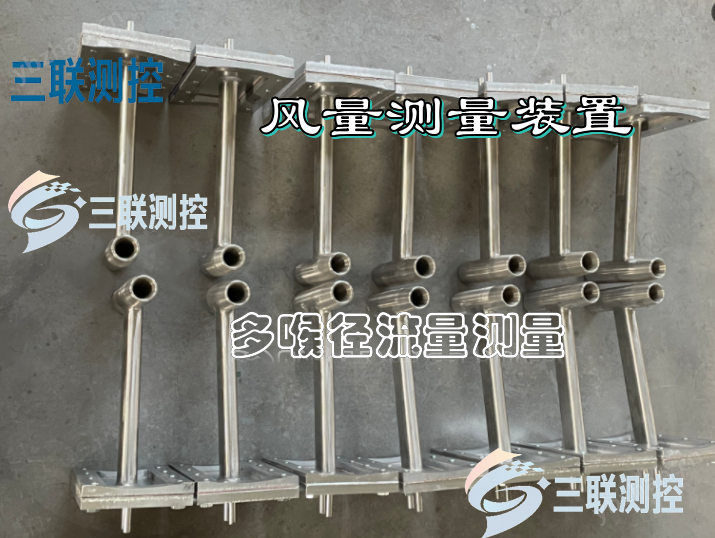

Multi throat flowmeter

1. The pressure loss is small, and the pressure loss of pipes with a diameter greater than 400mm can be ignored, which saves energy.

2. Low requirements for straight pipe sections. In general, the length of the front straight pipe section is 0.7-1.5D.

3. The differential pressure value is large. Under low flow rate conditions, a large differential pressure value is still obtained.

4. The signal is stable and reliable, with no pulsating differential pressure signal. Due to the use of a 'multi throat diameter' structure, the measured medium undergoes a 'rectification' process at each throttling section, effectively eliminating the influence of eddy currents to the greatest extent possible.

5. The special point structure can obtain measurement data of the entire pipeline cross-section, ensuring the authenticity and accuracy of the measurement.

6. The product has a long lifespan. The product is made of 316 ring 1Cr18Ni9Ti material and has undergone wear-resistant treatment on all fluid measurement surfaces, ensuring long-lasting wear resistance.

7. Adopting a special pressure structure to fundamentally avoid blockage. Online blowing and maintenance can be carried out through anti blocking blowing devices.

8. Small size and easy installation. Simply drill holes in the pipeline for installation, and the installation flange will be randomly assigned

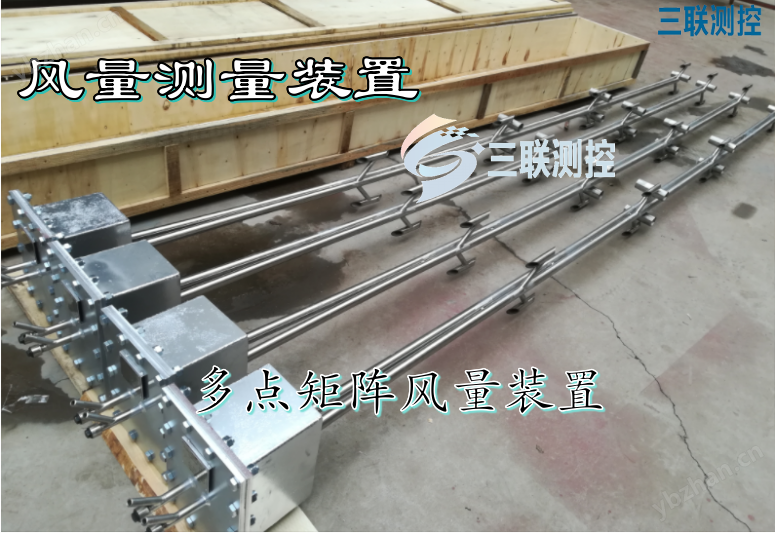

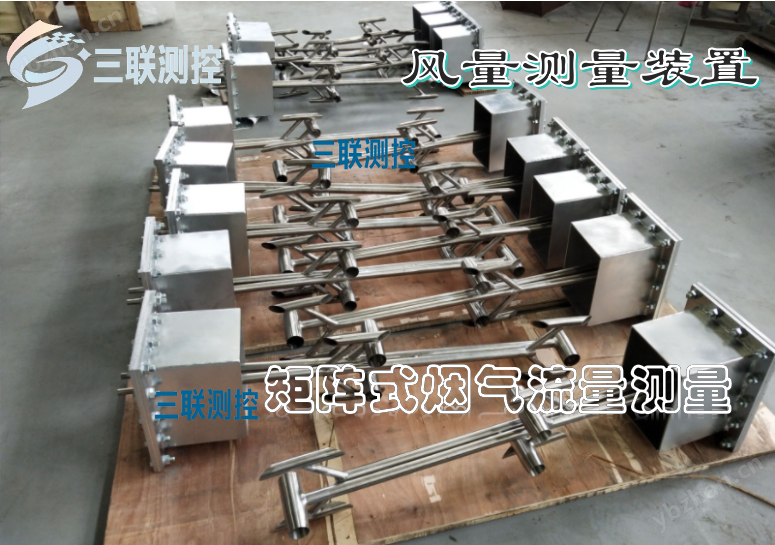

Multi point matrix air volume measurement device

1. Strong anti blocking performance

The improved sensor has made great breakthroughs in the pressure measurement point, fully considering the current widespread use status. Single point measurement has become multi-point measurement, and the design of multiple pressure holes, pressure points, and pressure directions has increased the anti blocking performance of the product, achieving no blowing and maintenance.

2. High output differential pressure

In the process of dynamic pressure measurement, when the total pressure remains constant, the acceleration suction effect of the throat tube is utilized to reduce the negative pressure to the minimum limit, greatly improving the differential pressure range. The characteristics are particularly prominent in flow measurement under conditions of large caliber, low static pressure, and low pressure loss.

3. The differential pressure signal is stable and has no pulses

Through the rectification effect of the contraction section and the pressure ring, the pulsation signal is maximally eliminated.

4. Wide measurement range

Can be used for measuring dry, humid gases, liquids, and vapor media without being limited by dielectric constant. For the measurement of high-density dust substances, only regular use of online blowing devices is required, ensuring flexible application in various working conditions.

5. The requirements for straight pipe sections are relatively low

The multi-point and multi-faceted pressure tapping method effectively balances the uniformity of pressure in the pipeline; Cold state simulation experiments have shown that satisfactory measurement results have been obtained with a front straight pipe section of 1D and a rear straight pipe section of 0.5D.

6. Small installation workload

For most plug-in work methods, it is usually only necessary to make holes in the pipeline, and then weld the exploration pipe to the pipeline to basically complete the on-site installation. It has a small volume and is easy to install

Delta flowmeter

1. Widely used for measuring various dry or humid gases, liquids, vapors, and other media;

2. The probe material has special 1.4528 and Hastelloy alloy, specifically designed for various strong corrosive media;

3. The low-pressure aperture is 8mm, with good anti blocking performance;

4. The probe has a symmetrical cross-section and can measure in both directions;

5. Low power loss in pipelines;

6. Small installation workload, free choice of integrated/split installation

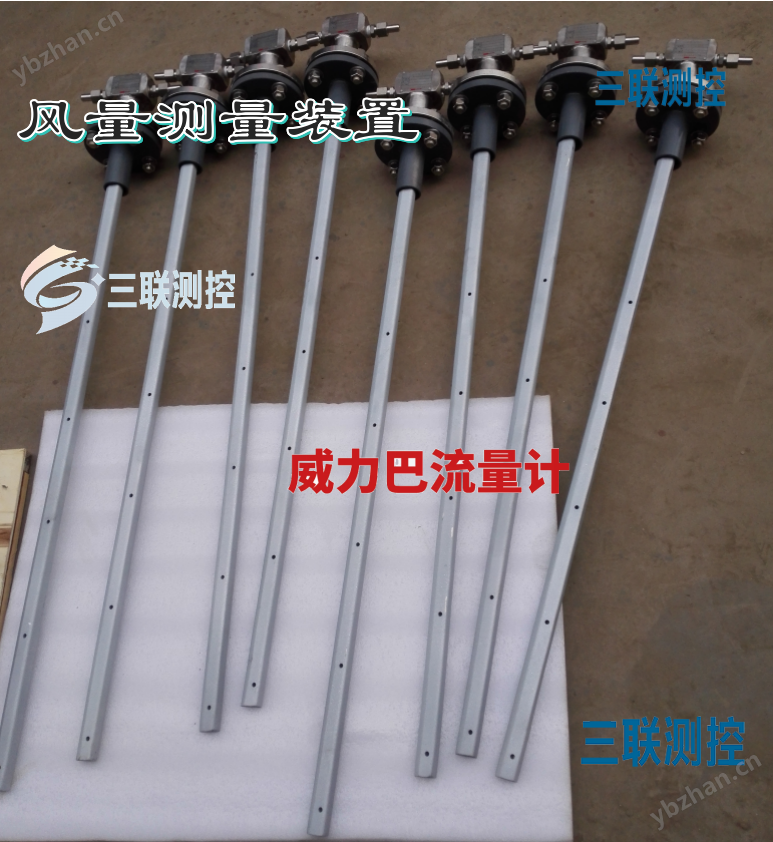

Velbar flowmeter

The manufacturer of the Weiliba flowmeter has summarized its wide range of applications, which are widely used for measuring various gases, liquids, and vapors. The following are typical application media:

1. Gas/liquid/vapor;

2. Natural gas/cooling water/saturated steam;

3. Compressed air/boiler water/superheated steam;

4. Gas/desalinated water;

5. Gas hydrocarbons/liquid hydrocarbons;

6. Hot air/low-temperature liquid;

7. Furnace gas/heat transfer liquid.