-

E-mail

51037070@qq.com

-

Phone

18028963555

-

Address

Room 113, Building 1, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Guangdong Derui Testing Equipment Co., Ltd

Anti damage test of packaging for bump vibration testing machine on Class III and IV highways

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

As a manufacturer, we provide professional express packaging testing solutions for the logistics and e-commerce industries.

1、 Why does express packaging require specialized anti damage testing?

The express transportation environment is harsh, and packages need to go through multiple loading and unloading, stacking, and long-distance bumps. Its damage mode has its own characteristics:

Multiple transfersThe package needs to go through multiple sorting, loading and unloading, and short distance transportation, and the cumulative vibration effect is significant.

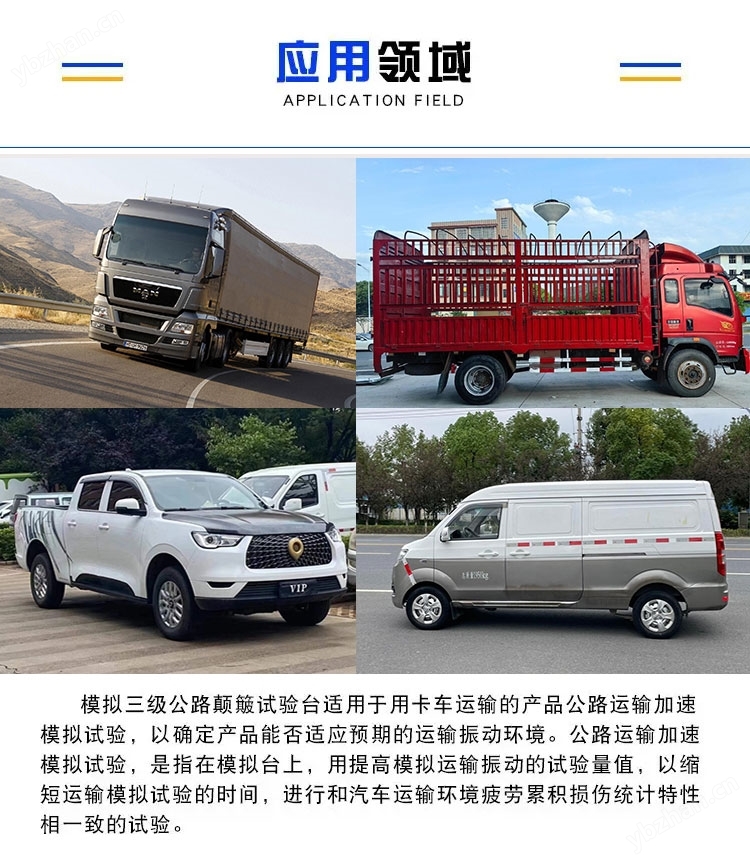

Complex road conditions: From urban roads to township level III and IV roads, the vibration spectrum is complex and there are many impacts.

Cost sensitiveThe packaging cost is extremely low and must beOn the premise of ensuring safetyAccurately control every penny and avoid excessive packaging.

Diverse interior contentsFrom documents and textiles to small electronic products, different packaging strategies are required due to varying sensitivity to vibration.

2、 Characteristics of customized testing machine solutions for the express delivery industry

The equipment we recommend focuses onEfficient, practical, and cost-effectiveTo meet the testing needs of massive express packages.

Suitable load and tabletop:

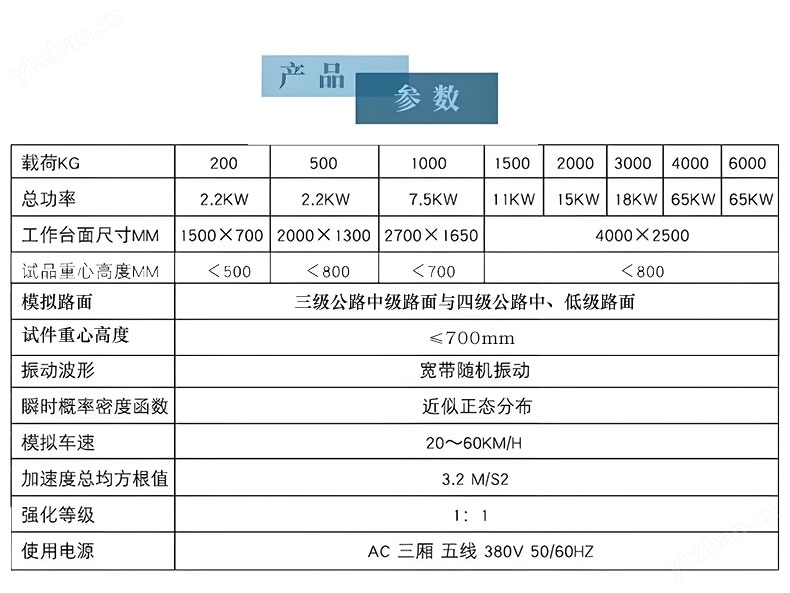

Recommended load:100kg - 200kg。 Capable of covering the weight of the vast majority of express packages.

Recommended countertop1000mm x 1000mm or 1200mm x 1200mm. Multiple small and medium-sized express boxes can be placed simultaneously to improve testing efficiency.

Efficient and authentic testing mode:

Core mode: Random vibrationThis is the most realistic and efficient model for simulating road transportation. It can effectively simulate the cumulative damage effects of long-term transportation in a relatively short period of time, and the results are very reliable.

Mode: sweep frequency and fixed frequencyUsed for quickly identifying resonance points of specific packaging components and conducting targeted reinforcement testing.

Built in standard program: PresetISTA 1A, 2A, 3A(Very suitable for e-commerce packages)ASTM D999TheGB/T 4857.7Waiting for the testing program, one click call, extremely simple operation.

Intelligent management and output:

Automatically generate reportsImmediately generate a professional report with vibration curves after testing, which can be used for internal process optimization and presentation to customers, demonstrating packaging reliability with data.

Barcode Management(Optional): The system can be integrated to associate test reports with waybills, facilitating quality traceability.

Durable and Safe:

The device has a sturdy structure and can adapt to long-term, high-frequency testing rhythms.

Easy to operate, safe and reliable, ordinary employees can operate with simple training.

3、 The core value that testing brings to you

Significantly reduce the damage rateDiscovering packaging defects in the laboratory in advance can avoid huge compensation and customer loss during actual transportation.

Scientifically optimizing packaging costsThrough testing, find packaging solutions that can both protect the product and be economical (such as reducing fillers and using cheaper materials), and bid farewell to packaging based on experience. Each package saves a few cents, but the total amount is very considerable.

Building brand reputationShowcase your scientific packaging testing process to the market, establish a "safe and reliable" brand image, and become a powerful marketing tool.

Quick arbitration disputeWhen damage occurs, it can be scientifically determined through testing whether it is a packaging issue, product issue, or improper transportation, reducing liability disputes.

4Anti damage test of packaging for bump vibration testing machine on Class III and IV highwaysSuggestions for efficient testing process

Select samplesSelect representative products or new packaging solutions that need to be evaluated.

Packaging according to SOPPack according to existing or pending packaging standard operating procedures.

Machine testingSelect the corresponding testing standard (such as ISTA 3A) and start the device.

Evaluation resultsAfter the test is completed, immediately open the box and inspect the product and packaging status.

passIncorporate this plan into the standard library and promote its use.

Not passedAnalyze the reasons, optimize the packaging, and retest until it passes.

Anti damage test of packaging for bump vibration testing machine on Class III and IV highwaysNext cooperation suggestion

To provide you with cost-effective solutionsExpress packaging testing planPlease provide the following information:

Main package typesWhat types of express packages do you usually handle? (such as small electronic items, clothing, food, paper products, etc.)

Package specificationsWhat is the approximate size and weight range of the vast majority of packages?

Test purposeIs it used for internal packaging optimization or provided as a value-added service to customers?

budget rangePlease provide an approximate budget, which will help us accurately match the most suitable model for you.

We are well aware of the pain points and needs of the logistics and express delivery industry. Our goal is to provide you with a practical device that is not just a decoration, but can truly save you money and generate revenue. Welcome to contact us for exclusive solutions and successful cases for the express delivery industry!