-

E-mail

guanshikeji@guanshikeji.com

-

Phone

19170336680

-

Address

3-4/F, Building 31, No. 5 Chaoyang 2nd Road, Chaoyang Industrial Park, Xinzhou District, Shangrao City, Jiangxi Province

Product Categories

Jiangxi Guanshi Technology Co., Ltd

Automated online metal ore material analyzer

NegotiableUpdate on 01/21

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

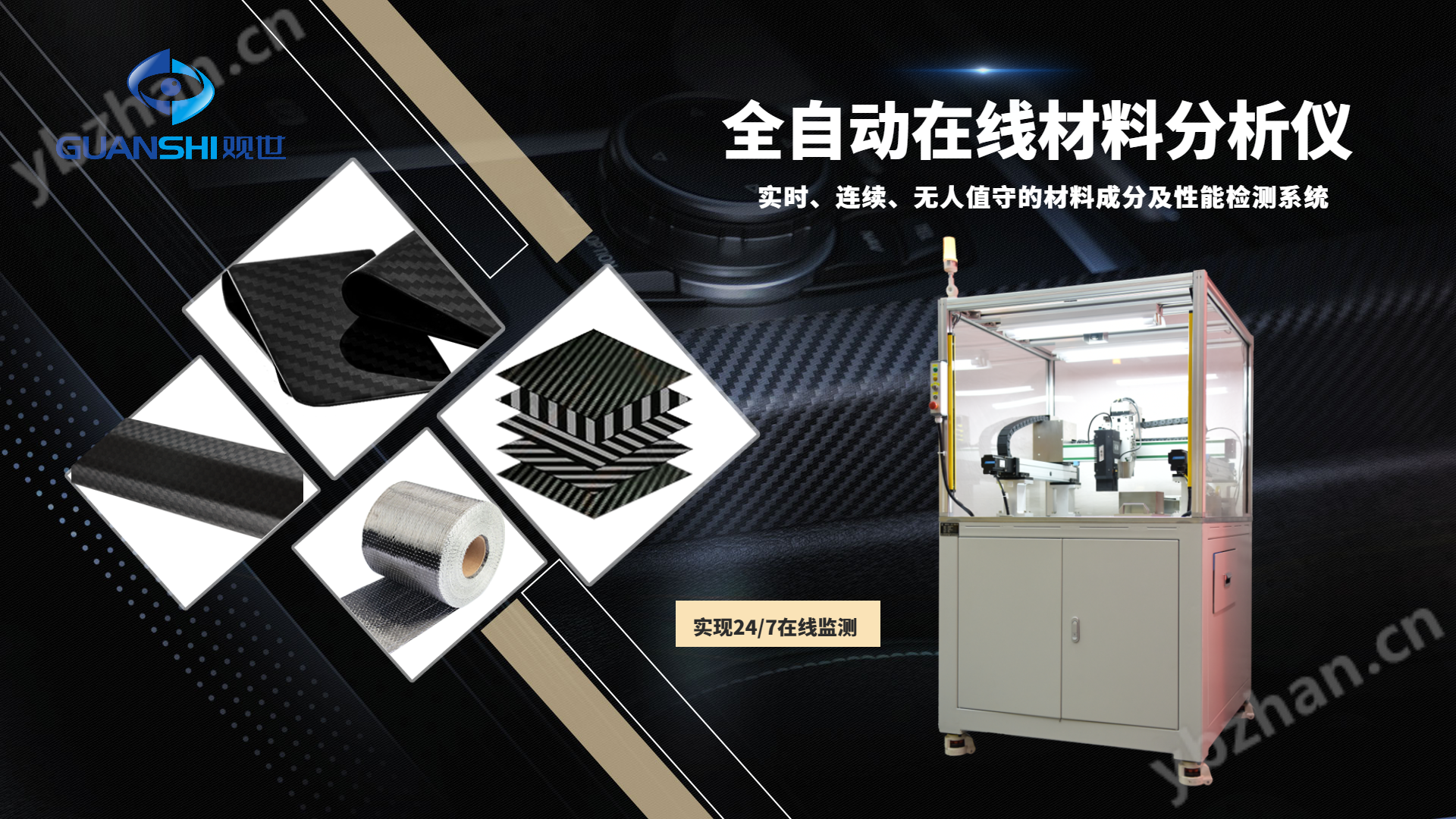

Automated online metal mineral material analyzer, integrating automation technology and X-ray fluorescence spectroscopy technology, relying on mature spectral analysis principles, can quickly and non destructively detect the chemical composition of steel products, metal products, and alloy materials, helping users build an online quality control system for products. It can control quality in real time without interrupting the production process and is widely suitable for testing needs in multiple fields such as manufacturing and geological exploration.

Product Details

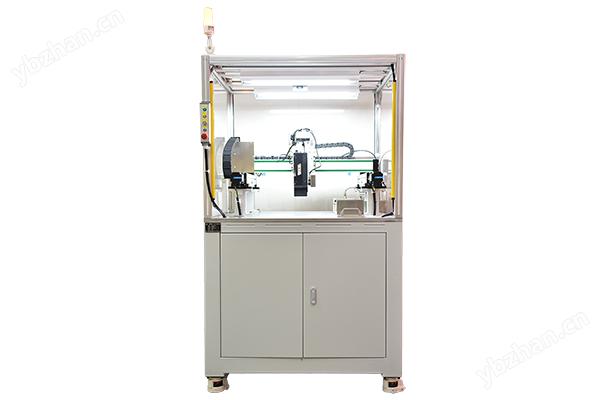

Automated online metal ore material analyzer

By integrating automation technology and X-ray fluorescence spectroscopy technology, relying on mature spectral analysis principles, rapid non-destructive testing of the chemical composition of steel products, metal products, and alloy materials can be carried out, helping users build an online quality control system for products. Quality can be controlled in real time without interrupting the production process, and it is widely applicable to the testing needs of multiple fields such as manufacturing and geological exploration.

Application of Automated Online Metal Ore Material Analyzer in the Industry

metal material

It can cover full element detection of ferrous metals (such as iron, chromium, manganese alloys) and non-ferrous metals (such as copper, aluminum, zinc alloys), suitable for the entire process of metal manufacturing: from component verification when raw materials enter the factory, to avoid unqualified raw materials from being put into production; Sampling inspection of semi-finished products during the production process and timely adjustment of process parameters; From quality control before the finished product leaves the factory, to component identification during the recycling of scrap metals, to ensure the rational utilization of resources.

Geological and Mineral Resources

For geological exploration scenarios, the composition analysis and lithology judgment of ore cores can be completed, which is applicable to both rapid screening in field exploration sites and batch sample testing in laboratories. Exploration personnel do not need to transport samples to the laboratory for a long time, and can obtain data on site, which helps to quickly evaluate the value of mineral points, divide the distribution of mineral layers, and shorten the exploration cycle.

Product Features

The equipment meets the needs of efficient detection with eight advantages: fully automatic design supports fully automatic testing, without the need for complex operations by professional personnel; The intelligent function can automatically identify the height of samples and adapt to samples of different thicknesses and shapes, without the need for manual parameter adjustment; Array based automatic data acquisition reduces data bias in a single detection through multi-channel synchronous operations; Timeliness is reflected in real-time data transmission, which can be integrated with enterprise production management systems or geological databases, facilitating data traceability and aggregation; The high efficiency feature significantly liberates manual labor, replaces the cumbersome process of traditional manual sampling and sample delivery, and greatly improves detection efficiency; Based on standardized calibration algorithms, ensure accurate and reliable data that meets industry testing standards; Non destructive testing does not damage the sample, and after testing, the sample can continue to be used for production or research, avoiding waste; The convenience of not requiring sample preparation, eliminating pre-processing steps such as cutting and grinding, and allowing for testing anytime, anywhere; At the same time, the design does not require contact with chemical substances, avoids the hazards of reagent corrosion and toxic substances, and complies with safety operation regulations.

Similar Product Recommend