-

E-mail

2880263323@qq.com

-

Phone

18761593852

-

Address

No. 5 ASEAN Road, ASEAN Industrial Park, Nanzha Town, Jiangyin City, Jiangsu Province

Jiangsu Ankerui Electric Appliance Manufacturing Co., Ltd

BAK open AC current transmitter 485 communication for cement plants

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

In the production process of cement plants, a large number of high-power equipment (such as motors, fans, crushers, etc.) continue to operate, and real-time monitoring of current is the key to ensuring equipment safety and stable production. Open current transmitters are widely used in cement plants due to their ability to adapt to complex environments without the need for power-off installation

BAK open AC current transmitter 485 communication for cement plantsIt is used to monitor the core equipment of cement plants, such as rotary kilns, ball mills, grate coolers, etc., which are driven by high-power motors. The operating current directly reflects the equipment load and health status,

The open type AC current transmitter product applies the principle of electromagnetic induction to measure the AC current in the power grid in real time. It adopts constant current and linear compensation technology to isolate and transform it into a standard DC signal output. DC12V or 24V safe voltage can be widely used in the field of industrial automation.

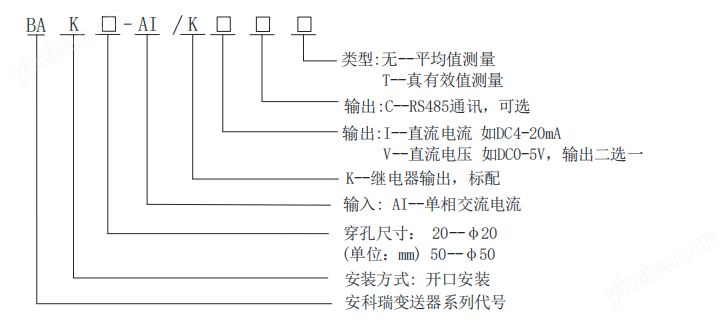

BAK open AC current transmitter 485 communication for cement plantsinterfaceModel Description:

Technical Specifications

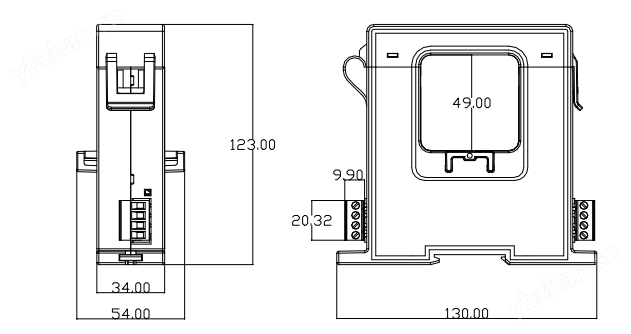

BAK20-AI

BAK50-AI

In the production process of cement plants, transmitters, as an important automated detection equipment, can provide accurate data support for production operations through real-time monitoring and transmission of key parameters such as temperature, pressure, flow rate, level, concentration, etc., bringing significant effects in various aspects:

Real time parameter monitoringThe transmitter can continuously and accurately monitor key parameters such as kiln temperature, preheater pressure, mill inlet and outlet pressure, and material level in the silo in real-time, and transmit the data to the control system (such as DCS system). Operators or automatic control systems can adjust production parameters in a timely manner based on this data, avoiding production instability caused by excessive parameter fluctuations (such as sudden rises and drops in kiln temperature that may cause problems such as ring formation and material blockage)

Reduce manual intervention errorsThe traditional manual inspection method for obtaining parameters has lag and subjectivity, while the automated monitoring of transmitters can eliminate human reading errors, ensure the timeliness and accuracy of parameter feedback, and keep the production process within a controllable range.

Precise control of key parametersIn cement production, parameters such as raw material ratio, clinker calcination temperature, and cement fineness directly affect product quality. For example, by monitoring the concentration of raw material slurry through an online concentration transmitter, the proportion of ingredients can be adjusted in real time to ensure the stability of raw material composition; By using a temperature transmitter to accurately control the calcination temperature inside the kiln, the quality of the clinker can be ensured to meet the standard.

Reduce the risk of quality fluctuationsBased on real-time data from transmitters, the control system can achieve closed-loop regulation (such as automatic adjustment of feeding amount, air volume, etc.), reducing product quality instability caused by parameter fluctuations (such as strength failure, abnormal setting time, etc.), and improving batch product consistency

Early warning of faultsThe transmitter can monitor the operating parameters of the equipment (such as motor bearing temperature, gearbox vibration, pipeline pressure, etc.). When the parameters exceed the normal range, the system will give an alarm in a timely manner (if the motor temperature is too high, it may indicate bearing wear). The operator can stop the machine for maintenance in advance to avoid the expansion of equipment faults (such as motor burnout, pipeline rupture) and reduce the losses caused by sudden shutdown.

Avoid overloading operationFor example, monitoring the inlet and outlet pressure of the mill through a pressure transmitter can determine whether there is a risk of material blockage; The vibration transmitter monitors the vibration amplitude of the crusher, which can avoid equipment overload caused by hard materials. These monitors can protect equipment from abnormal wear and tear, extending its service life.

Ultimately achieving production automation and intelligence

Data Integration and AnalysisThe parameters collected by the transmitter are the basic data for the informatization and intelligence of cement plants, which can be integrated with MES systems (manufacturing execution systems) and ERP systems to achieve centralized management and analysis of production data. By mining historical data, production processes can be optimized (such as adjusting kiln calcination curves), providing data support for decision-making.

Unmanned production supportIn automated production lines, real-time data from transmitters is the "eye" for robots, automatic valves, and other equipment to operate automatically. For example, automatic batching systems use data from flow transmitters to achieve precise feeding, reducing manual operations and providing support for intelligent production modes such as "black light factories".