-

E-mail

hengleyiqi@163.com

-

Phone

18340091069

-

Address

Jingshi West Road, Shizhong District, Jinan City, Shandong Province

Jinan Hengle Xingke Instrument Co., Ltd

Brake Beam Static Test Device - HLYQ

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Brake Beam Static Test Device - HLYQ

Brake Beam and Brake Shoe Fatigue Testing Machine - HLSYJ

Railway brake beam tension test device -200T

Railway brake beam tension test system

Railway brake beam fatigue tensile machine

Railway brake beam tension test system

Loading device for static load test of brake beam

Railway brake beam tension test system

Fatigue testing system for brake beams and brake shoes

Brake beam static load test device

Brake beam and brake shoe fatigue testing machine

Railway brake beam tension test device -200T

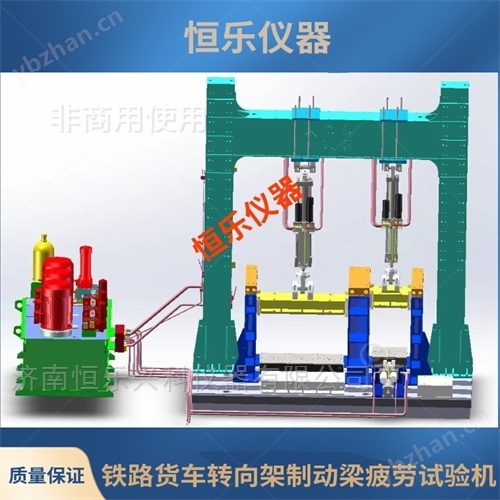

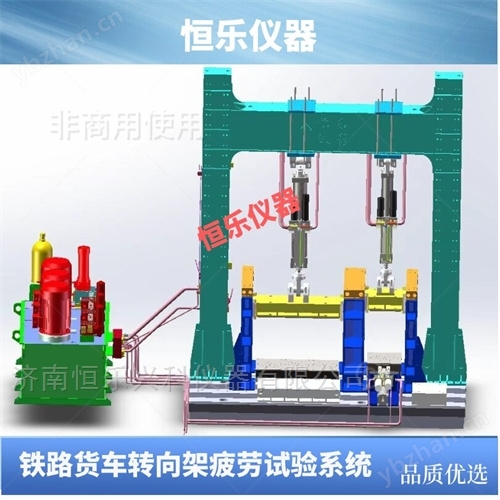

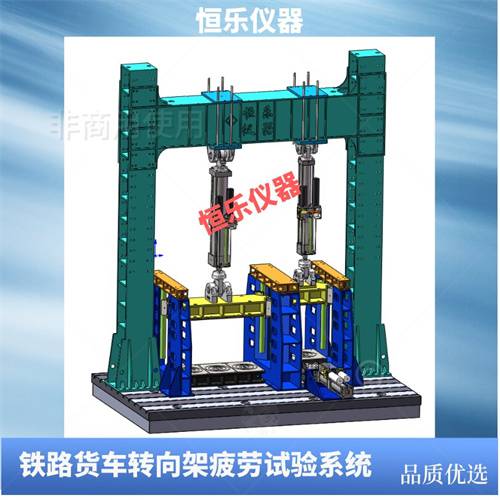

1. Main purpose:Brake Beam Static Test Device - HLYQ,Suitable for tensile testing of various types of brake beams on railway freight cars. It mainly consists of the body, supporting device, hydraulic loading system, sensors, micro control system, printer and other parts. Adopting a micro control operation mode, it can automatically judge the test results and print the tensile test report.

2. Technical parameters

Input power supply: AC380V ± 10% 50Hz three item five wire

Single machine power: 4kW

Cylinder stroke: 100mm

Hydraulic system pressure: 17MPa

Dimensions (length x width x height): 1682 x 460 x 825 (mm)

Pin diameter: 36mm

Test tension: 103.5kN

Test result output method: screen display+printing

3. Technical requirements

(1) The brake beam tension tester shall meet the relevant requirements of the "Maintenance Rules for Railway Freight Car Braking Devices" (Tieyun [2008] No. 15) document. The equipment is installed in the offline area, and the brake beam that needs to undergo tensile testing is automatically dispatched to the offline end through the brake beam maintenance line. The brake beam is automatically loaded and unloaded by the brake beam automatic loading and unloading robot and placed on the turnover box of the waiting repair station. It is transported by AGV stacking forklift to the station where the brake beam tensile tester is located.

(2) After the brake beam is loaded, the brake shoe support blocks at both ends, the center of the oil cylinder, the center of the support column, and the center of the brake beam frame should be on the same plane, and the force transmission should be on the same straight line.

(3) The brake shoe support block rotates slightly on the assembly pin shaft to eliminate force distribution; At the same time, the support block of the brake shoe bracket has an appropriate range of swing and can be adjusted with bolts to ensure that the support block is tightly attached to the brake shoe bracket.

(4) The displacement sensor is installed inside the linear bearing, and the centerline of the installation and commissioning bearing should be parallel to the centerline of the oil cylinder. The sensor slide should move freely vertically without any lateral force.

(5) Controlled by a touch all-in-one machine, the test results are automatically judged and uploaded to the MES system. The test results can be printed.

(6) The equipment should be equipped with a 2-meter fence for safety protection, and physical isolation should be implemented between humans and machines during testing.