-

E-mail

2628879629@qq.com

-

Phone

18066558480

-

Address

Standard Factory Building on Chuangye Avenue, New Industrial Park, High tech Zone, Xi'an City

Product Categories

Xi'an Xiangyuan Technology Co., Ltd

Brand of Xi'an Magnetic Flip Plate Liquid Level Gauge

NegotiableUpdate on 12/20

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The Xi'an magnetic flap level gauge is a level measuring instrument designed based on the principles of magnetic coupling and connector. It consists of a magnetic float, float, and magnetic flip column indicator. When the liquid level changes, the magnetic float moves inside the float, and the color of the magnetic flip column indicator also changes. Usually, white represents no liquid level, red represents liquid level, and the position between white and red is the measured liquid level height.

Product Details

1、 Product Introduction

The Xi'an magnetic flap level gauge is a level measuring instrument designed based on the principles of magnetic coupling and connector. It consists of a magnetic float, float, and magnetic flip column indicator. When the liquid level changes, the magnetic float moves inside the float, and the color of the magnetic flip column indicator also changes. Usually, white represents no liquid level, red represents liquid level, and the position between white and red is the measured liquid level height. The display panel of this liquid level gauge is a flip column, which is easy to observe.

The Xi'an magnetic flap level gauge has multiple advantages, such as precise measurement, intuitive indication, customizable display panel, and easy installation. It is suitable for medium level detection of various equipment such as towers, tanks, tanks, spherical containers, and boilers. In addition, there are various types to choose from according to different working environments and usage needs, such as anti-corrosion type, insulation jacket type, high temperature and high pressure type, top mounted type, etc.

It has been widely used in production and daily life. It is not only suitable for measuring and indicating the liquid level of flammable, explosive, corrosive, high-temperature, toxic and harmful, and turbulent environments, but also for measuring the liquid level of various liquids and gases. It should be noted that when selecting, appropriate materials and models should be chosen based on the properties of the measuring medium and the working environment to ensure the accuracy and reliability of the measurement results.

2、 Application scenarios

3、 Technical parameters

| medium pressure | Stainless steel ≤ 10Mpa, anti-corrosion ≤ 2.5Mpa |

| medium density | ≥0.5g/cm3 |

| medium temperature | -20~400℃ |

| medium viscosity | ≤10-4m2/S |

| measurement accuracy | ±10mm |

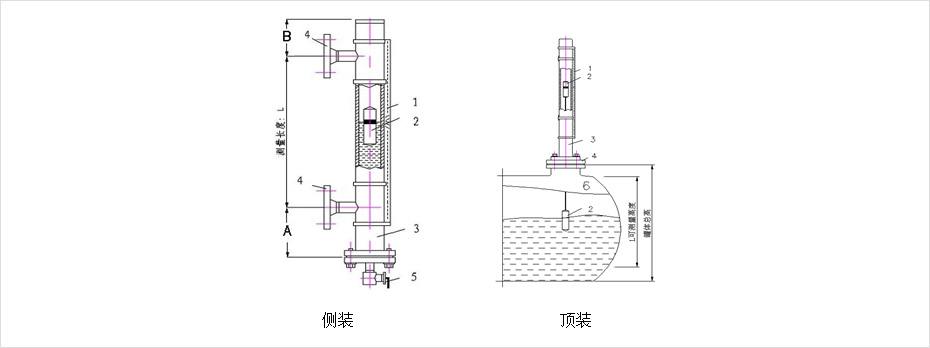

| Installation method | Flanged side mounted type |

| Protection level | IP65 |

| Install flange | According to user requirements |

| Discharge flange | Default is DN25-GB |

| Float specifications | φ 51, φ 57 (wall thickness depends on pressure and temperature) |

| Float material | 304/316L/PP/PVC/PTFE lined |

| functional facilities | Standard type (on-site flipping display) Remote transmission type (on-site flipping display+signal remote transmission) Alarm type (local flip panel display+alarm switch) Remote alarm capability (on-site flipping display+signal remote transmission+alarm) |

4、 Installation method

5、 Accessories

The transmitter is tied to the outside of the main tube of the magnetic flap level gauge with a clamp, so that it is in the same magnetic coupling system as the level gauge. When the magnetic float moves up and down with the liquid level, the dry spring chip group corresponding to the liquid level position is affected and moved by the magnetic field inside the float, and the resistance chain value changes. The changed resistance signal is converted into a 4-20mADC standard signal through a conversion module and transmitted to the secondary instrument PLC、DCS, Thus achieving the purpose of liquid level display, control, regulation, and alarm.

Fixed on the magnetic flip plate measuring cylinder with clamps; The transmitter box can be installed at the top or bottom;

Attention: The transmitter is an electronic precision component and is strongly affected by the environment. The normal operating temperature range is -40~85 ℃. Beyond this range, there may be unclear display or communication interruption.

Similar Product Recommend