-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

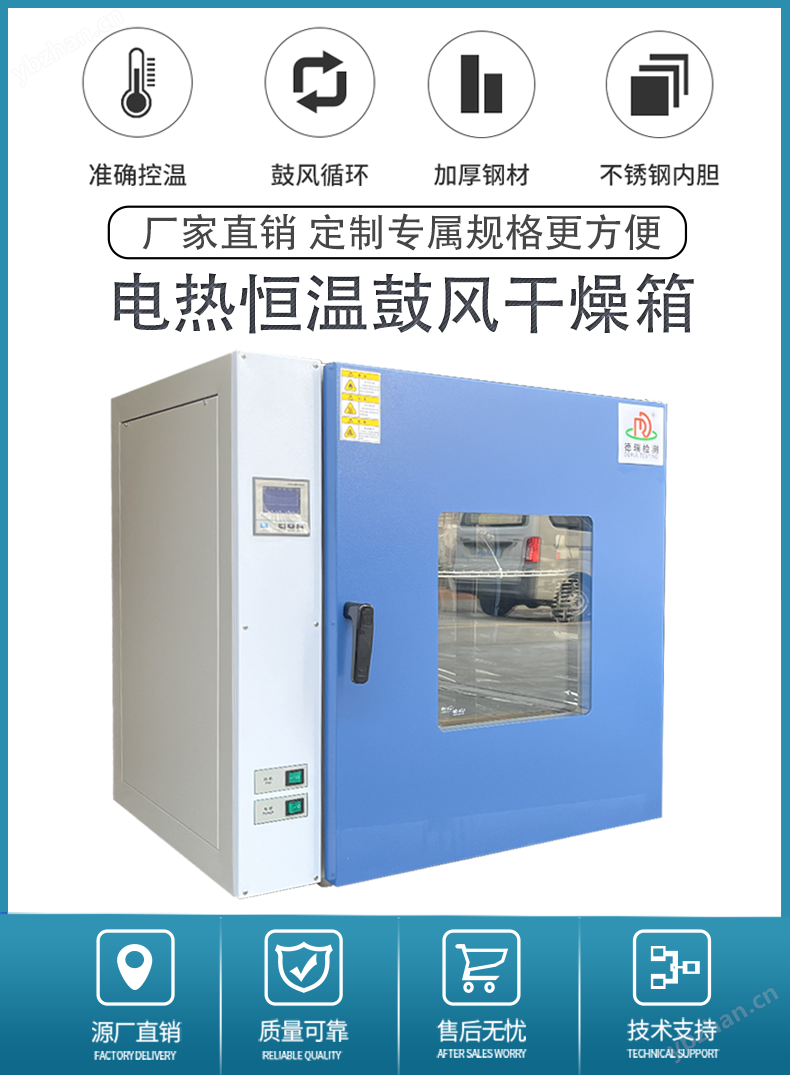

Chemical raw material drying electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

In the chemical production process, the drying treatment of raw materials is a key link that directly affects the quality and efficiency of subsequent processes. As a common drying equipment, electric blast drying oven has become the choice of many chemical enterprises due to its stable performance and wide applicability. This article will discuss the working principle, key technical characteristics, application scenarios, and operational pointsChemical raw material drying electric blast drying ovenIntroduce the system.

1、 Working principle and structural composition of the equipment

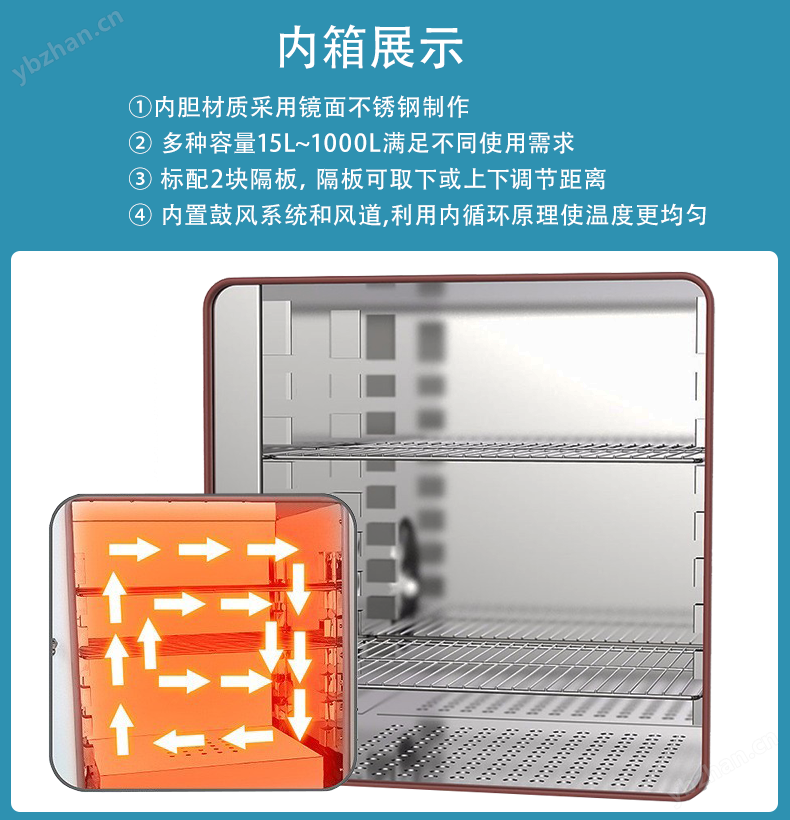

The electric blast drying oven generates heat through an electric heating system, combined with forced convection driven by a fan, to ensure uniform air flow inside the oven, thereby achieving rapid drying of materials. Its core structure includes the following parts:

heating systemUsually, resistance wires or electric heating tubes are used as heat sources, which can provide an adjustable heating range.

fan systemUsing a centrifugal fan to circulate the air inside the box, ensuring even temperature distribution.

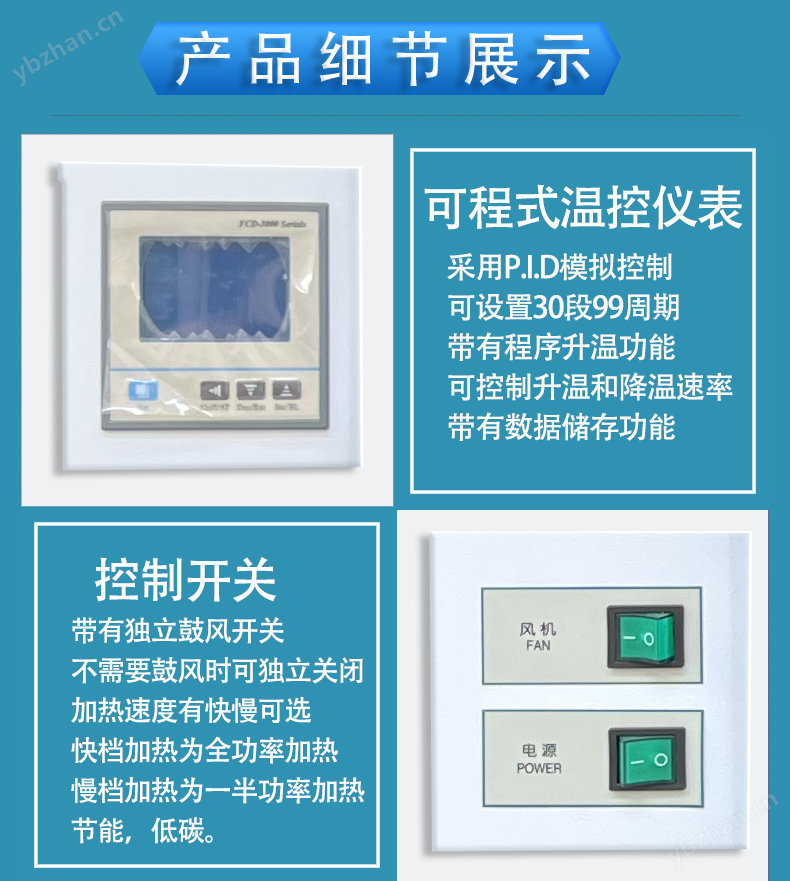

control systemIncluding temperature controller, timer, and safety protection device, used for precise control of the drying process.

Box StructureMostly made of stainless steel material, it has good insulation and corrosion resistance.

2、 Key technical characteristics

The performance of an electric blast drying oven depends on the synergistic effect of multiple technical parameters. The following is a comparison of its main characteristics:

| feature classification | specific description |

|---|---|

| Temperature control accuracy | Adopting PID regulation, the temperature difference inside the box is small |

| Fan type | Low noise centrifugal fans with adjustable airflow are commonly used |

| safety protection | Equipped with functions such as over temperature protection and motor overload protection |

| Material Selection | The inner liner is commonly made of stainless steel, and the outer shell is made of cold-rolled steel plate sprayed with plastic |

In practical use, users may ask:How to determine if a drying oven meets the drying needs of chemical raw materials?The key is to evaluate its temperature uniformity, air volume adjustment range, and material tolerance. For example, some easily oxidizable raw materials need to choose models with inert gas interfaces, while environments with high dust levels require attention to the explosion-proof design of the equipment.

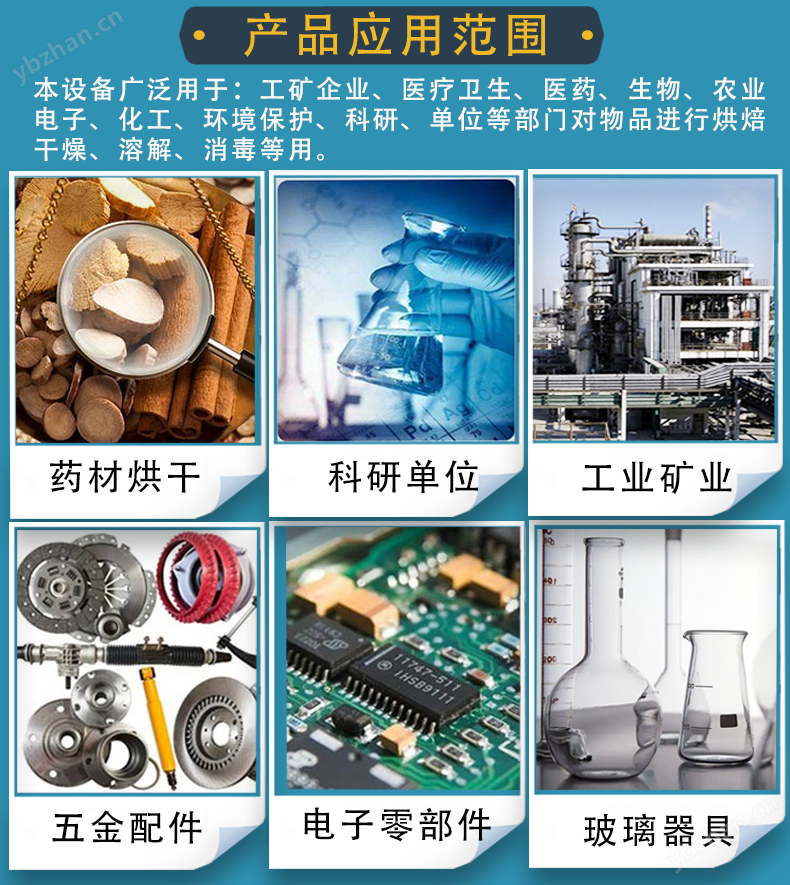

3、 Application scenario analysis

The diversity of chemical raw materials determines that the drying oven needs to adapt to different scenarios:

Drying of powder raw materialsFor materials such as calcium carbonate and silicon dioxide, attention should be paid to matching the thickness of the paving material with the wind speed;

Crystalline material processingDuring the drying process, it is necessary to control the heating rate to avoid damage to the crystal structure;

Intermediate dryingSome intermediate products after synthesis reactions are sensitive to humidity and require rapid removal of surface moisture;

Experiment and Small Batch ProductionDuring the research and development phase, the drying oven can be used for exploring and optimizing process parameters.

It is worth noting that the thermal stability of different materials varies greatly. For example, some organic raw materials may decompose at higher temperatures, so suitable drying conditions need to be determined through experiments.

4、 Operation points and maintenance

A standardized operating procedure is a prerequisite for ensuring the long-term stable operation of equipment:

Loading requirementsThe materials should be evenly spread on the tray to avoid excessive accumulation that may affect the penetration of hot air;

Parameter SettingsSet a step heating program based on material characteristics to avoid sudden temperature changes;

Cleaning and maintenanceRegularly clean the residue inside the box and check if the fan is running normally;

troubleshootingIn case of significant temperature fluctuations, it is important to focus on checking the sensor position and fan direction.

Why is maintenance more important than repair?Regular replacement of sealing strips, cleaning of air ducts, and other simple maintenance can effectively prevent equipment performance degradation and extend its service life.

5、 Frequently Asked Questions and Answers

Q: What is the reason for material clumping after drying?

Answer: It may be due to excessive temperature causing surface melting, or uneven heating of the material during spreading.

Q: How to improve energy efficiency?

Answer: Waste heat recovery design can be adopted, or the most suitable drying time can be selected according to the characteristics of the material.

Conclusion

Chemical raw material drying electric blast drying ovenAs a fundamental equipment in chemical production, its technological development has always revolved around improving accuracy and expanding adaptability. With the emergence of new materials and processes, future equipment may be further optimized in intelligent control, energy-saving design, and other aspects. For users, understanding the principles of the equipment and operating it in a standardized manner is essential to fully leverage its technological advantages and provide reliable support for chemical production.