-

E-mail

1832549464@qq.com

-

Phone

18352321309

-

Address

No. 188, Jinhu County Industrial Park, Huai'an City, Jiangsu Province

Jiangsu Jianheng Instrument Co., Ltd

Coal mine level gauge price

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Coal mine level gauge priceThe level gauge for coal mine dust storage tanks adopts the principle of capacitance measurement, which is suitable for continuous measurement of liquid level and solid level of various conductive and non-conductive media in industrial production processes, especially suitable for use in strong acid and alkali and high temperature (200 ℃) media. It is to transmit and receive extremely short microwave pulses with very low energy through an antenna system. Radar waves travel at the speed of light. The running time can be converted into level signals through electronic components. A special time extension method can ensure stable and accurate measurements in a very short period of time.

Even in complex working conditions with false echoes, the XYRD800 series radar level gauge can accurately analyze the echoes of the level using * * new microprocessor technology and debugging software.

applicationCoal mine level gauge price

Chemical plant: detecting the liquid level of chemical raw materials such as polyester, spandex, acid, alkali, etc

Environmental Protection: Detecting Sewage Level

Boiler factory: Detecting the liquid level of the medium inside the pressure vessel

Hydraulic Machinery: Detecting Lubricating Oil Level

Grain department: Detecting the liquid level of edible oil

Oilfield: Detecting the liquid level of finished oil products

Paint Factory: Detecting Paint Level

Powder silo: Material testing for coal powder, cement, plastic pellets, grains, feed, flour, and other storage bins

Features:

1. Compact structure, small size, easy installation and maintenance.

2. Polytetrafluoroethylene probe, resistant to strong corrosive liquids such as acid, alkali, and high temperature.

3. Multiple signal output forms can be used for different system configurations.

4. The measuring part immersed in liquid only has one PTFE flexible wire or PTFE rod probe as a sensor, with high reliability.

The body also integrates temperature and pressure compensation functions, which can measure the standard volume flow rate or standard mass flow rate of fluids.

Fully intelligent and digital circuit design, capable of automatically compensating for measured fluid density or standard condition volume calculation.

The new digital filtering and correction functions make flow measurement more accurate and reliable.

The battery powered type can work continuously for more than two years without the need for an external power source.

New dot matrix Chinese character LCD display, more convenient to use and operate.

technical indicators

Measurement range: 0.2~20 meters

Accuracy: Level 0.5, Level 1.0

● Extreme temperature resistance: -40~250 ° C

● The transmitter is suitable for ambient temperature: -40~60 ° C

Allowable container pressure: -0.1Mpa~32.0MPa

Measurement medium: Non crystalline conductive liquids such as acids, bases, and water with a conductivity of not less than 10-3S/m.

Power supply: DC12~35V (isolated type is DC21~27V)

Output signal: 4~20mA (0~10mA, 0~20mA)

Output protection: 27mA

Range adjustment range and zero shift: ≥ ± 30% FS

The application areas are suitable for liquid level measurement in power, metallurgy, chemical, food, pharmaceutical, sewage treatment, boiler steam drums, etc.

Selection Table

Wiring:

The transmitter is a standard two-wire or three wire instrument, and the power (signal) terminal is located on the wiring side inside the instrument housing. The signal line should use shielded wire or twisted pair wire with two knobs together, and should not be passed through conduit or exposed trunking together with other power lines, nor should it be passed near high-power equipment.

Installation and Debugging:

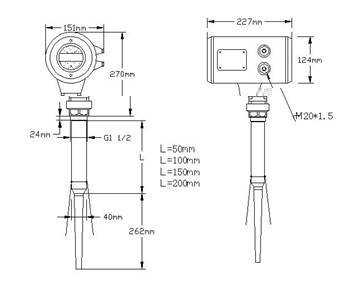

Cable and rod level transmitters have multiple installation and fixing methods to adapt to different on-site situations. When process facilities such as M20 × 1.5 internal threads or flanges cannot be provided on site, there are three installation methods to choose from: wall mounted, horizontal pipe rack mounted, and vertical pipe rack mounted, making it easy for you to install on site.

When measuring media with high fluidity, to prevent the sensor from swinging violently, users can choose a counterweight accessory to stabilize the sensor. When adding a counterweight, be sure to place the counterweight object at the bottom of the container to avoid damaging the sensing wire.

When the on-site environment is harsh, users should use sensor protective covers to protect the sensors from being damaged by foreign objects or affecting the accuracy of measurements.

When using a rod type liquid level transmitter, if it is not a metal container, the transmitter housing needs to be connected to the bottom of the container with a wire, otherwise the measurement will be inaccurate.

If on-site adjustment is required for the product, the following methods can be adopted:

When the liquid level is below *, slowly rotate the "Z" potentiometer with a screwdriver and observe that the reading on the ammeter is close to 4mA.

When the liquid level is above *, slowly rotate the "S" potentiometer with a screwdriver and observe that the reading on the ammeter is close to 20mA.

Repeat this process 2-3 times or more until the zero point and range are accurate at 4mA and 20mA, respectively.

After adjustment, the cover of the transmitter should be tightened.

Technical parameters

Measurement medium: liquid, gas, vapor

Medium viscosity: less than 10cp

Medium temperature: -50 ℃ -+400 ℃

Body material: 1Cr18Ni9Ti (supplied under other material agreements)

Sensor sealing: graphite gasket (special according to requirements)

Environmental temperature: -30 ℃ -+80 ℃ (depending on specific requirements)

Nominal diameter:

Pipeline type: DN15- DN300;

Insertion type: DN200-2000mm

Measurement accuracy:

Liquid: ± 0.5% of measured value (special)

Gas: ± 0.5% of measured value

Range ratio: 10:1

Pressure rating: PN25, PN40 (high pressure can be specially manufactured)

Connection method:

Clamping type DN15-DN300

Flange type DN15-DN300.

Plug in DN200-DN2000

防爆形式:

Explosion proof Ex d Ⅱ BT4-T6

Intrinsically safe Ex ia Ⅱ CT4-T6

Protection level: IP67

Converter housing: die cast aluminum, painted

Supply voltage: 12-36VDC or 3.6V battery

Output signal: two-wire 4-20mA current output

On site display: programmable to display instantaneous flow and cumulative flow

Communication method: RS485 communication

Measurement conditions

Precautions

- The measurement range starts from the point where the beam touches the lower part of the tank, but in special cases, if the tank is concave or conical, measurement cannot be carried out when the level is below this point.

- If the medium has a low dielectric constant and is visible at a low liquid level, it is recommended to set the zero point at a low height of C to ensure measurement accuracy.

- In theory, it is possible to measure the position of the antenna, but considering the effects of corrosion and adhesion, the final value of the measurement range should be at least 100mm away from the antenna.

- For overflow protection, a safe distance can be defined to be added to the blind spot.

- ***The small measurement range is related to the antenna.

- With different concentrations, foam can both absorb microwave and reflect it, but it can be measured under certain conditions.

Actions beyond the measurement range

When the measurement range exceeds, the instrument outputs a current of 22mA.

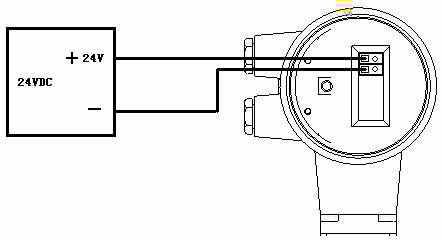

Wiring method

Debugging

XYRD800 can be debugged in three ways:

- By displaying the adjustment module SKPM

- Debugging software SKSOFT

- Using a HART handheld programmer

|

On site Programming Module (XYPM)

|

|

|

|

Debugging through BTSOFT software

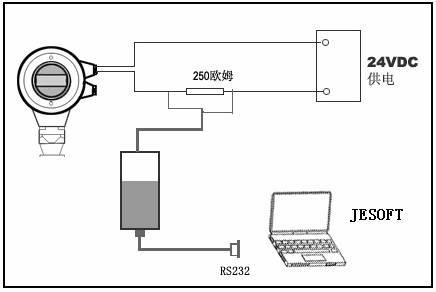

Regardless of the signal output, 4... 20mA/HART, radar sensors can be debugged through software. Using BTSOFT software for instrument debugging requires a CONNECTCAT driver for the instrument.

When debugging software, power up the radar instrument with 24VDC and add a 250 ohm resistor to the front end of the HART adapter. If the instrument is powered by an integrated HART resistor (internal resistance of 250 ohms), there is no need to add an external resistor, and the HART adapter can be connected in parallel with 4... 20mA wires.

XYRD800 series dimensions

Programmer size