-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

Coarse Profile Confocal Microscope

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

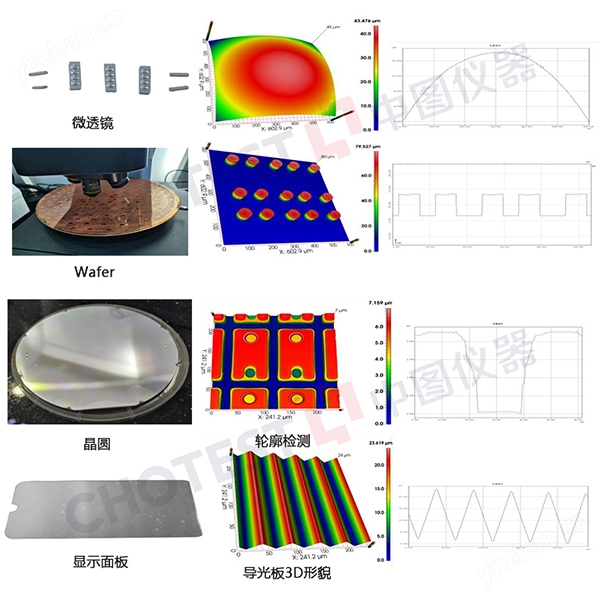

Zhongtu Instrument VT6000Coarse Profile Confocal MicroscopeHaving the characteristic of intuitive measurement, it can effectively improve work efficiency and complete daily tasks more quickly and accurately. Mainly used for micro nano level measurement of various precision devices and material surfaces, empowering efficient control in the ultra precision machining industry, such as semiconductor manufacturing, 3C electronics, aerospace and other ultra precision machining fields.

1、 Industry measurement pain points

Are you facing these challenges:

1. Insufficient precision in microstructure measurement

2. Low efficiency in large-scale detection

3. Complex operation leads to high labor costs

4. The risk of equipment collision affects the service life.

Zhongtu Instrument VT6000Coarse Profile Confocal MicroscopeWith high stability design and breakthroughs in core technology, we aim to address industry pain points and provide accurate, efficient, and safe measurement solutions for B2B customers, becoming the core driving force for quality control and R&D innovation!

2、 Core values

1. Double improvement in accuracy and efficiency: Under the same objective lens, the lateral resolution is higher, the image details are clearer, the intuitive measurement mode+batch analysis function significantly shortens the detection cycle, and reduces time costs.

2. Full scene measurement coverage: from nanometer to micrometer level, whether it is smooth/rough surfaces, low/high reflectivity materials, key parameters such as roughness, flatness, and micro geometric contours can be accurately measured.

3. Dual guarantee of safety and stability: dual collision protection+intelligent energy-saving design of light source, reducing equipment loss, extending service life, and reducing operation and maintenance costs.

4. Compliance: Compliant with multiple industry international standards such as ISO/ASME/EUR/GBT, with over 300 2D/3D parameter measurement capabilities and traceable data.

3、 Core functions

1. 3D+2D Full Dimensional Measurement: Simultaneously achieve micro 3D morphology characterization and 2D plane size (length, angle, radius, etc.) measurement, with one device meeting the needs of multi-dimensional detection.

2. Efficient detection in large areas: The automatic splicing function covers a wide range of measurement scenarios, without the need for manual splitting, avoiding data discontinuity and improving detection integrity.

3. Intelligent data processing: four modules of adjustment, correction, filtering, and extraction+five analysis tools (roughness/geometric contour/structure, etc.), one-stop data processing, supporting custom template batch analysis.

4. Convenient operating experience: Integrated X/Y/Z three-axis joystick, can quickly complete translation and focusing, supports speed adjustment and light source brightness control, even beginners can quickly get started.

5. Security protection upgrade: lens spring structure+pressure sensor, automatic emergency stop after collision; Unmanned time source intelligent extinguishing, balancing equipment protection and energy conservation.

4、 Performance advantages

1. High precision guarantee: Rotary confocal optical system+3D reconstruction algorithm, combined with seismic isolation design, reduces vibration interference, accurate and highly repeatable measurement data, and reduces rework risks.

2. Integrated software platform: Measurement and analysis can be operated on the same interface without the need to switch windows. The scanning process can be visualized and monitored in real-time, and data can be automatically collected to generate charts, improving decision-making efficiency.

3. Flexible adaptation requirements: Supports one click analysis, multi file combination analysis, can save custom templates, adapts to batch sample testing scenarios, and reduces manpower investment.

5、 Applicable industries

1. Core application areas: semiconductor manufacturing and packaging, 3C electronic glass screens and precision accessories, optical processing, micro nano material manufacturing, automotive components, MEMS devices.

2. Expand application scenarios: aerospace component testing, research and development experiments in research institutes, quality control in the ultra precision machining industry, etc.

6、 Take immediate action

The VT6000 confocal microscope empowers enterprises with technological innovation to reduce costs, increase efficiency, and upgrade quality, making it the preferred partner for B2B customers in the field of precision measurement.

Product information will be updated in real-time based on technological iterations, with more customized application solutions, parameter details, and quotations. Please feel free to contact Zhongtu Instrument for consultation at any time, and we will provide you with one-on-one professional services!

If you need to learn more about industry cases or schedule prototype testing, you can directly send a private message or leave a message, and we will connect you with a dedicated consultant as soon as possible~