-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

Coordinate measurement laser tracker

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Zhongtu Instrument GTSCoordinate measurement laser trackerWith the core advantages of μ m level accuracy and hundred meter level measurement range, we integrate multiple technologies and intelligent solutions to solve measurement pain points such as insufficient measurement accuracy of large-sized workpieces, difficult detection of complex features, low assembly efficiency, and poor adaptation to multiple environments. Provide comprehensive high-precision measurement solutions for scenarios such as ultra large workpieces, industrial mother machines, and large-scale scientific devices.

1、 Product advantages

1. Breaking through measurement limitations: Balancing 15 μ m+6 μ m/m spatial accuracy with a measurement radius of 30-80 meters, easily covering the full dimensional measurement needs of large and ultra large workpieces.

2. Improve production efficiency: The data output speed reaches 1000 points per second, and high-precision scanning can be completed without sticking points, reducing the number of repeated adjustments by more than 30%.

3. Adapting to complex scenarios: IP54 protection level, paired with an integrated weather station, capable of meeting the measurement needs of multiple environments such as workshops and outdoors with ease.

4. Reduce overall costs: GTSCoordinate measurement laser trackerIntegrate the full process functions of measurement, calibration, and analysis, replace multiple traditional instruments, and reduce equipment investment and operational complexity.

2、 Diversified Technologies and Intelligent Solutions

1. Dual degree of freedom series, covering different measurement scenarios

(1) GTS3000 series (three degrees of freedom): Equipped with an optical retroreflector target ball, it accurately measures basic geometric features such as points, lines, surfaces, and curved surfaces in large-scale space.

(2) GTS6000 series (six degrees of freedom): compatible with iProbe/iTracer 6D attitude probe/sensor, easily tackling complex measurement challenges such as internal and hidden features.

2. Intelligent configuration enhances measurement capabilities

(1) EyeScan tracking laser scanning system: Visual dynamic tracking technology enables real-time high-precision scanning of large and medium-sized objects, with simple and efficient operation.

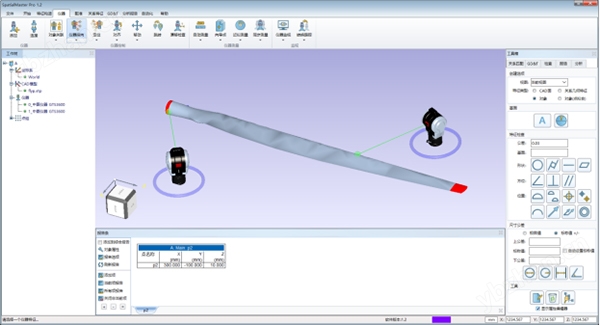

(2) Independently developed core software: SpatialMaster (PTB certified) supports multi instrument collaborative measurement and GD&T evaluation, while RobotMaster suite enables rapid calibration of robots.

3、 Key technical indicators

Note: Product parameters and configurations may be adjusted due to technological upgrades, please refer to actual communication for details.

4、 Application Cases

1. Precision calibration of industrial robots

(1) Customer pain point: The absolute position accuracy of the robot is poor, which cannot meet the requirements of precision stacking and assembly. Traditional calibration lacks data support.

(2) Solution: Paired with the RobotMaster kit, collect data from 50 different points and compare and correct it with the theoretical values of the DH model.

(3) Actual test results: After calibration, the maximum position accuracy of the robot was reduced to 0.5mm, and the pose repeatability was improved to 0.005 °, which meets the requirements of GB/T 12642 standard and high-precision operation.

2. Installation and adjustment of the fan-shaped base of the continuous casting machine

(1) Customer pain points: Traditional hanging wire measurement has low efficiency, data deviation caused by environmental differences before and after adjustment, and high repeat rework rate.

(2) Solution: Laser tracker point acquisition+SMT software modeling+external data compensation to ensure that all sectors are measured and adjusted in the same environment.

(3) Actual test results: The entire process of installation and adjustment takes only one-third of the time of traditional methods, with measurement accuracy of 15 μ m+6 μ m/m, avoiding repeated adjustments caused by data deviation and greatly improving installation and adjustment efficiency.

3. Calibration of large gantry machine tools

(1) Customer pain points: The calibration of machine tool flatness and straightness is complex, requiring multiple devices to cooperate, and the difficulty of horizontal adjustment is high.

(2) Solution: Quickly generate a horizontal plane through gravity alignment function, compare the absolute difference between the work platform and the horizontal plane, and monitor and adjust in real-time.

(3) Actual test effect: Replacing laser interferometers to achieve linear/angular accuracy measurement, adjusting accuracy to micrometer level, ensuring machine tool processing quality, and reducing equipment investment costs.

If you are facing difficulties in precision measurement, please feel free to contact us for exclusive solutions and case details. We will provide you with one-on-one technical consultation and on-site demonstration services.