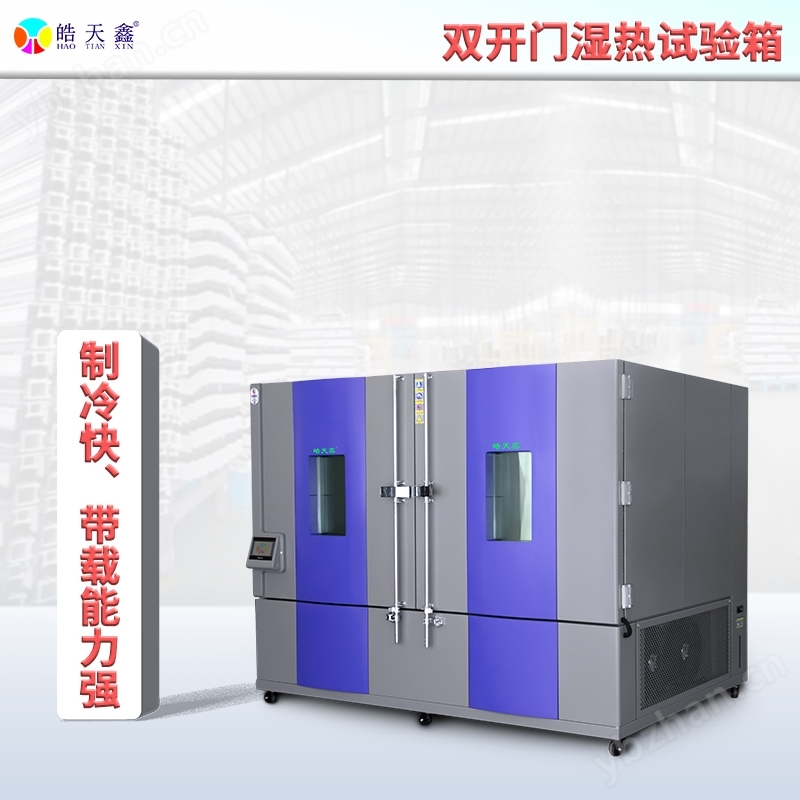

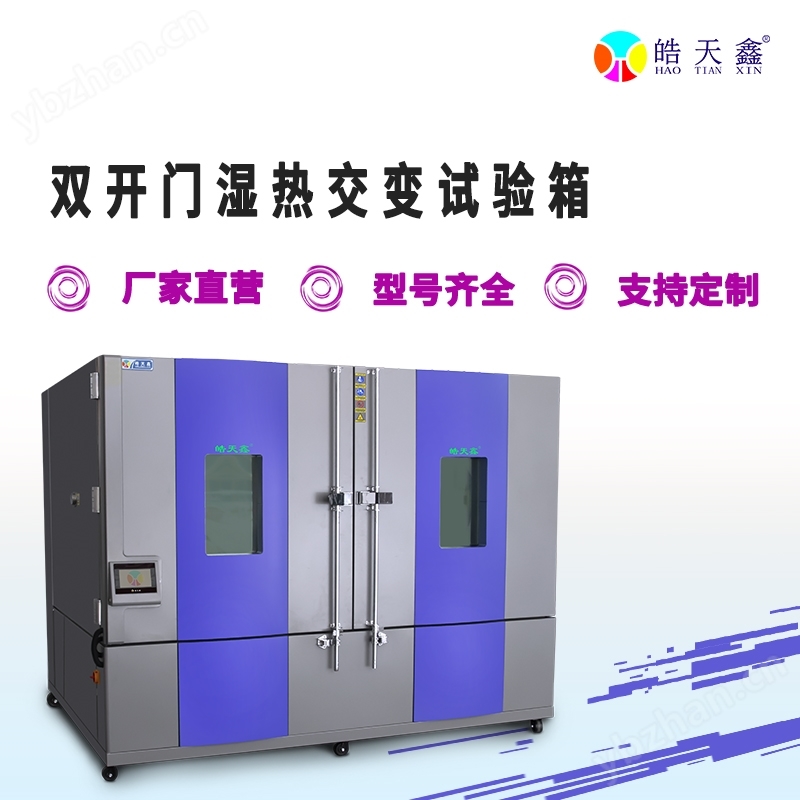

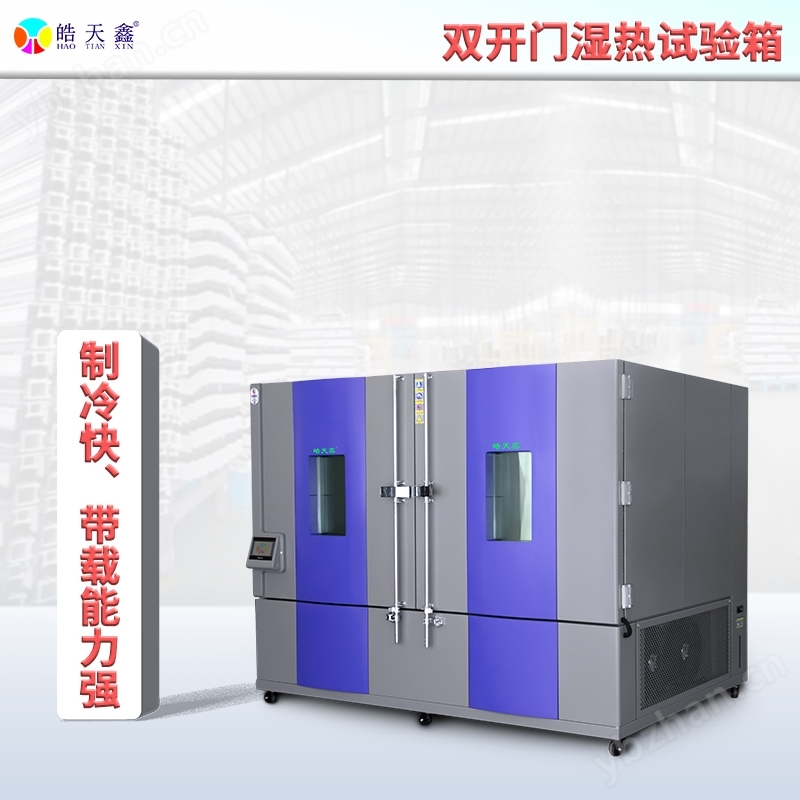

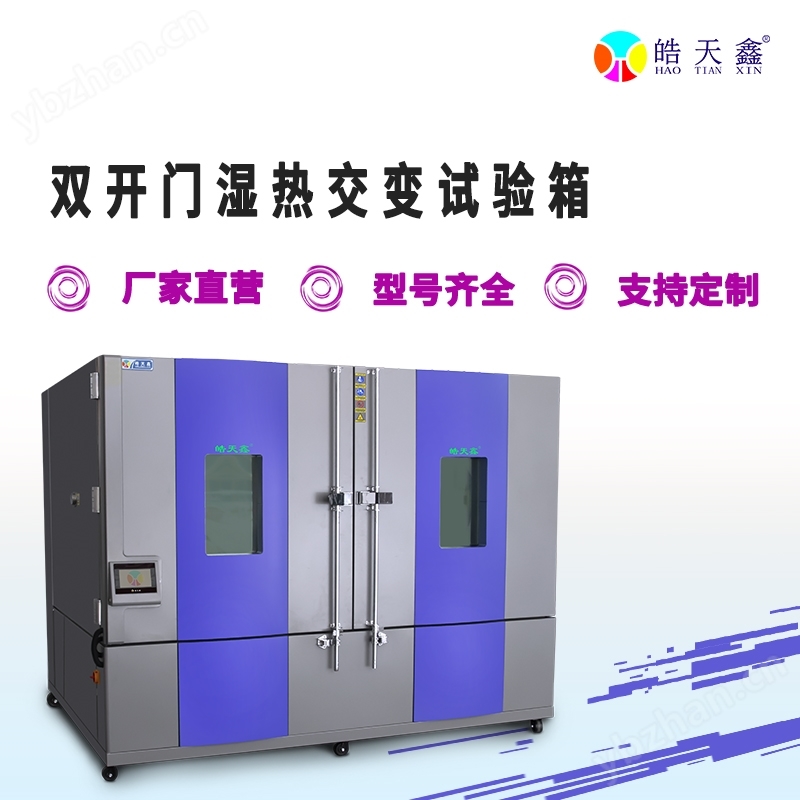

Customized temperature control test box with double doors and vertical height can meet the testing needs of multiple industries such as electronic appliances, automotive parts, plastic hardware, medical equipment, textiles, food, etc., such as high and low temperature reliability testing of electronic components, wet and hot aging testing of automotive parts, and temperature and humidity storage stability testing of food.

Customized temperature control test box, constant temperature and humidity test box, double door vertical type

performance metrics

Uniformity of temperature and humidityWithin ± 2.0 ℃, the humidity uniformity is within ± 3.0% RH to ensure the accuracy and consistency of the test results.

Temperature and humidity fluctuationAt around ± 0.5 ℃, the humidity fluctuation is around ± 2% RH, and a stable temperature and humidity environment is the basis for ensuring the accuracy of the test.

Heating and cooling rateSelect the appropriate heating and cooling rate according to the experimental requirements. Generally, a heating rate of 3 ℃/min and a cooling rate of 1 ℃/min can meet most conventional experimental needs, but special experiments need to be selected according to actual requirements.

Customized temperature control test box, constant temperature and humidity test box, double door vertical type

Box structure and material

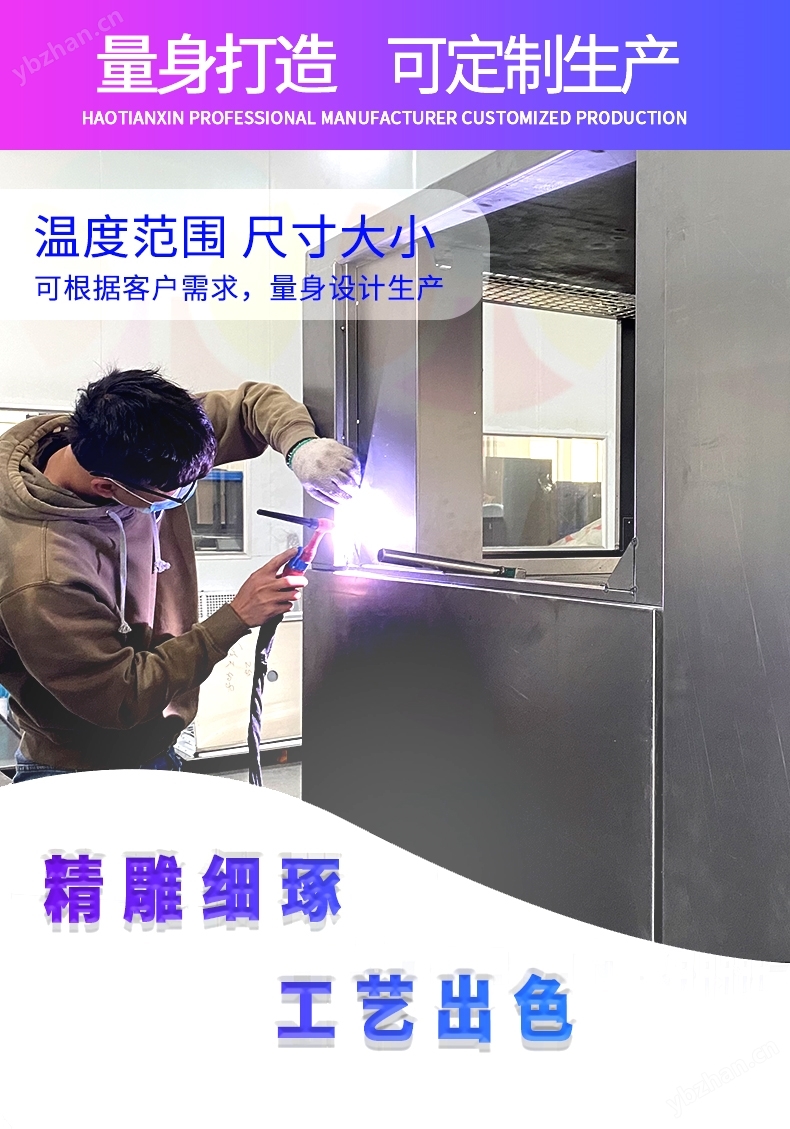

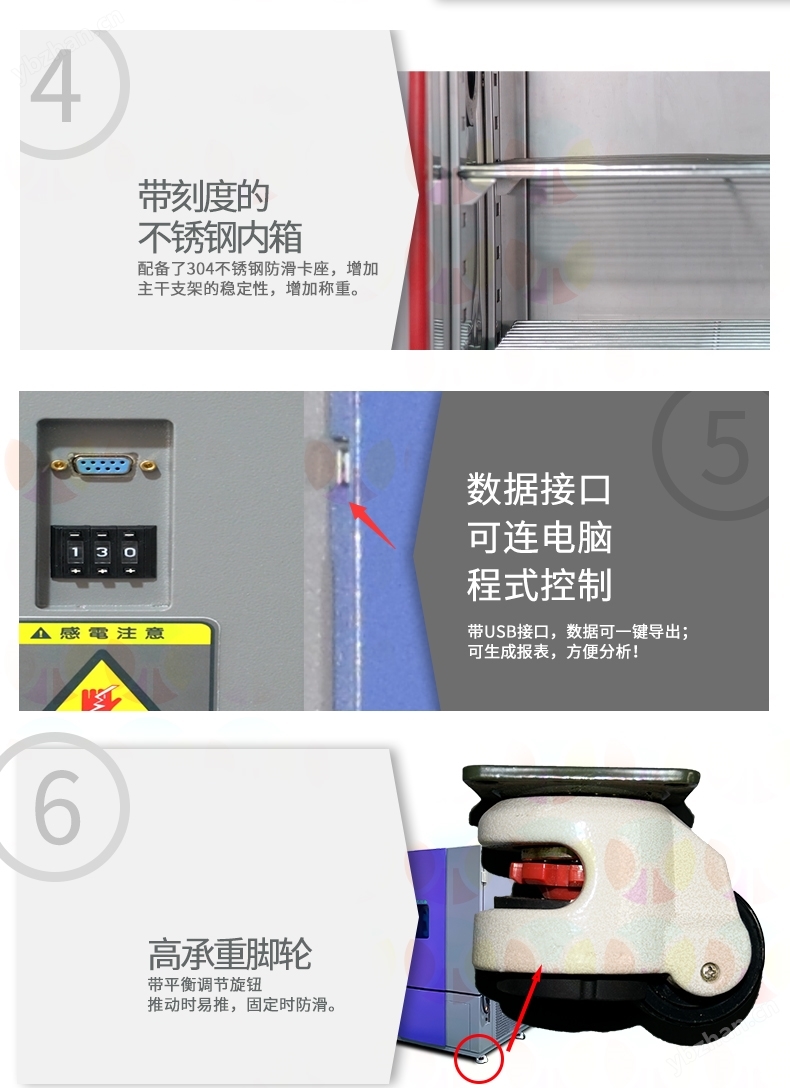

Inner box materialThe commonly used SUS # 304 stainless steel plate has good corrosion resistance and high temperature and humidity resistance, which can effectively resist corrosion in temperature and humidity environments without causing pollution to the testing environment.

outer box materialThe outer box mainly serves the functions of protection and insulation. The steel plate is made of baked paint material, and the thickness of the steel plate is generally around 1.0mm. This material not only has a certain strength, but also the baked paint treatment can enhance the aesthetics and rust prevention performance.

thermal insulation materialHigh quality insulation materials are the key to maintaining stable temperature and humidity inside the box. The combination of hard polyurethane foam and glass wool is a common and effective insulation method, and the thickness of the insulation layer is usually between 80-100mm.

Box door designThe double door design facilitates the retrieval and placement of large-sized samples. The box door should be equipped with a good sealing strip, such as silicone foam, to ensure effective isolation between the inside environment and the outside when closed. At the same time, a non reactive flat handle should be embedded

Easy to operate.

control system

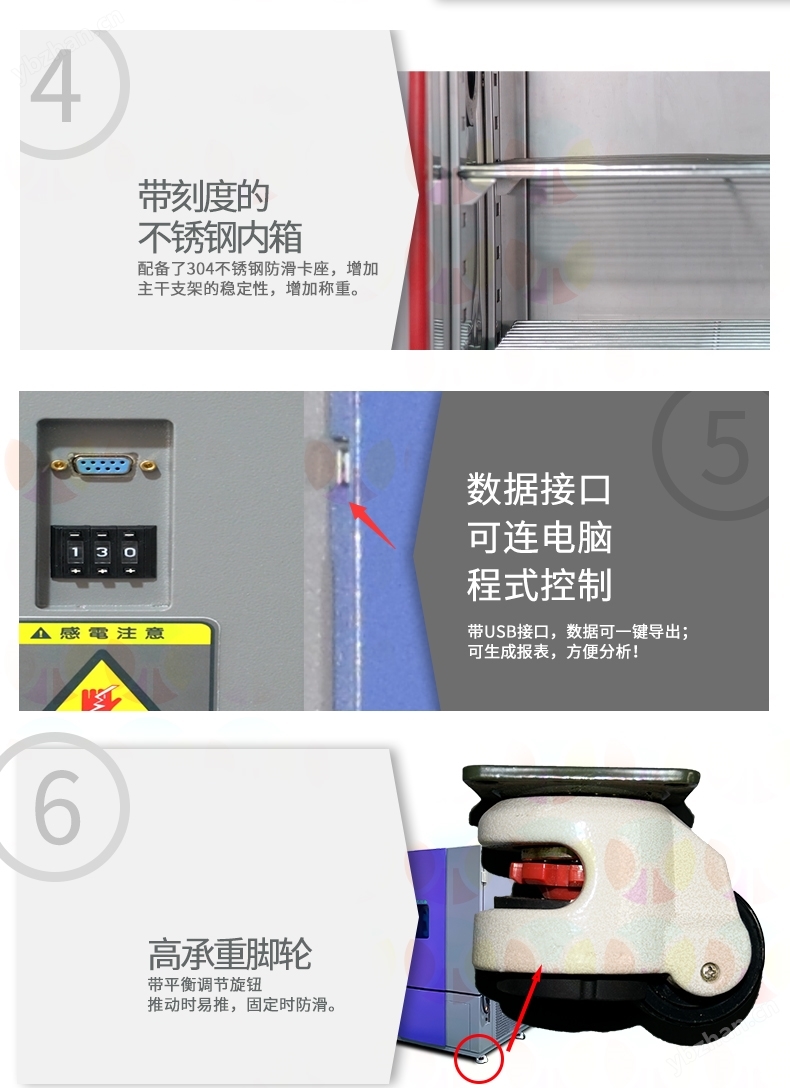

Controller functionThe controller has precise temperature and humidity control capabilities and rich programming functions, which can achieve multi-stage program editing to meet different requirements for temperature and humidity in different experimental stages. At the same time, it has real-time display of temperature and humidity data, fault alarms, and other functions.

sensor accuracyThe accuracy of the temperature sensor should reach ± 0.1 ℃, and the accuracy of the humidity sensor should reach ± 1% RH, so as to timely and accurately feedback the temperature and humidity changes inside the box and provide reliable data support for the controller.

Data recording and communicationThe test chamber should have data storage function, which can store long-term temperature and humidity data. At the same time, it should be equipped with communication interfaces such as RS232 or RS485 to facilitate connection with computers and achieve remote transmission and monitoring of data.

Security protection function

It should have basic safety functions such as over temperature protection, overload protection, and leakage protection. In addition, water shortage protection, condensate overflow protection, threshold protection, etc. can also be considered to further improve the safety and reliability of the equipment.

-

Before all maintenance operations, be sure to cut off power and water, and wait for the equipment to cool down to room temperature before proceeding to avoid electric shock and burns.

Do not use hard brushes or sharp tools during cleaning to avoid scratching the inner liner, fins, and sensors.

Do not spray water directly onto electrical components and motors to prevent short circuit faults.

After maintenance, keep records (time, content, discovered problems, and handling results) for easy traceability of equipment status.