-

E-mail

1534513049@qq.com

-

Phone

15566891672

-

Address

No. 38, West Section of Century Road, Pulandian District, Dalian City, Liaoning Province

Dalian Yiste Technology Co., Ltd

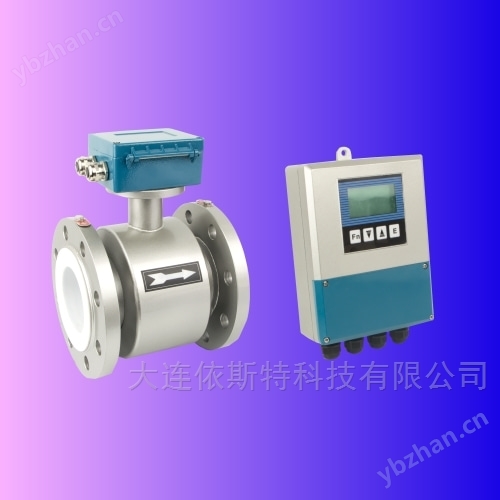

DN300 pipe section electromagnetic flowmeter

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Comprehensive analysis of Dalian Yister YST183F-A50XL equipment

1、 Product Introduction

2、 Advantages and Characteristics

Accurate and stable measurement: Our YST183F-A50XL equipment is not affected by physical properties such as medium viscosity, density, temperature, and pressure, and the measurement accuracy can reach ± 0.5% FS (or ± 0.2% FS in some scenarios), meeting the high-precision measurement needs of large-diameter pipelines.

Easy installation and maintenance: Adopting a pipe section flange connection design, it matches the standard flange of a 300mm nominal diameter pipeline. Installation does not require complex modifications, and daily maintenance only requires regular checks of electrode cleanliness without disassembling the entire machine.

Strong anti-interference ability: Equipped with built-in anti electromagnetic interference circuit and signal filtering technology, it can resist the interference of industrial field frequency converters, motors and other equipment, and can still stably output signals under complex working conditions.

Corrosion resistance and wide adaptability: The sensor material can be selected from corrosion-resistant materials such as stainless steel and Hastelloy, and can adapt to various corrosive media such as sewage, chemical wastewater, acid and alkali solutions.

Low operating costs: No mechanical rotating parts, minimal wear and tear, long lifespan, no need for frequent replacement of vulnerable parts, long-term operation and maintenance costs significantly lower than traditional flow measurement equipment.

3、 Technical parameters

Measurement range: 0.1-10m/s (flow velocity range), corresponding to a nominal diameter of 300mm pipeline flow range of approximately 8.5-848m ³/h (converted based on pipeline cross-sectional area).

Accuracy level: ± 0.5% FS (conventional), ± 0.2% FS (high-precision customized).

Working pressure: PN1.0MPa, PN1.6MPa, PN2.5MPa (optional, suitable for different pipeline pressure levels).

Medium temperature: -20 ℃ -120 ℃ (conventional), -40 ℃ -180 ℃ (customized for high temperature).

Dielectric conductivity: ≥ 5 μ S/cm (required, suitable for the vast majority of industrial and municipal water and wastewater).

Output signal: 4-20mA analog signal, HART protocol, RS485 (Modbus RTU) digital signal (optional).

Power supply: AC220V ± 10% 50/60Hz, or DC24V ± 10%.

Protection level: Sensor IP67, IP68 (optional), converter IP65.

Connection method: flange connection (compliant with GB/T 9119, HG/T 20592 and other standards, suitable for nominal diameter 300mm pipe flanges).

4、 Selection criteria

Confirm the characteristics of the medium: Clearly measure the conductivity (≥ 5 μ S/cm), corrosiveness, solid content, etc. of the medium, and select the sensor electrode and lining material based on this (such as corrosion-resistant lining suitable for chemical wastewater).

Matching operating condition parameters: Based on the actual working pressure and temperature of the pipeline, select the corresponding pressure level and temperature range configuration to avoid operating beyond the range.

Meet installation requirements: Ensure that the installation location has sufficient straight pipe sections (10 times the diameter of the front pipe and 5 times the diameter of the rear pipe), away from disturbance sources such as valves, elbows, and pump bodies, and reserve maintenance space.

Clear measurement requirements: Select the accuracy level according to the measurement purpose, and determine the output signal type based on the data transmission requirements (such as RS485 digital signal required for smart water systems).

Compatibility of Face Adaptation System: Confirm that the product communication protocol is compatible with the on-site control system (such as PLC, DCS, smart water platform) to ensure seamless data integration.

5、 Application industry

Wastewater treatment plant: Our YST183F-A50XL equipment can be used for flow measurement in key processes such as inlet, outlet, sludge return, and dosing pipelines, providing data support for process control and discharge accounting.

Waterworks: Adapt to processes such as raw water intake, clean water transportation, and pipeline distribution, accurately measure the total amount of water supply, and assist in water volume scheduling and cost accounting.

Water purification plant: used for monitoring the flow rate of filtered water transportation and disinfection processes to ensure stable water treatment processes and meet water supply quality standards.

Municipal water supply network: installed at the nodes of municipal main pipelines and partition pipelines to achieve real-time monitoring of water supply, support pipeline leakage control and water pressure regulation.

Environmental water treatment: suitable for flow measurement in industrial wastewater pretreatment, reclaimed water reuse, sewage upgrading and transformation projects, meeting environmental acceptance and emission reduction accounting requirements.

Thermal heating: Measuring the flow rate of hot water in the heating network to assist in heat distribution and energy consumption statistics at the heating station, and improving heating efficiency.

Hospital wastewater treatment: adapted for flow monitoring of bacterial and disinfectant wastewater in hospitals, taking into account corrosion resistance and accurate measurement, in compliance with environmental standards for medical wastewater treatment.

Chemical wastewater treatment: used for flow measurement of high salt and high corrosion wastewater in chemical enterprises. The sensor material can be selected from acid and alkali resistant materials, suitable for complex wastewater conditions.

River water quality monitoring: Installed at river monitoring sections, diversion channels, and other locations, combined with water quality sensors, to achieve flow water quality linkage monitoring and support water environment governance.

Smart rural water management: adapted to flow monitoring of rural centralized water supply and sewage treatment stations, with equipment supporting remote data transmission to meet the centralized control needs of smart water management platforms.

6、 Technology Trends

Intelligent upgrade: Integrated IoT module, supporting 4G/NB IoT remote communication, realizing real-time uploading of traffic data, remote monitoring, and fault warning, adapting to the needs of smart water management.

High precision development: Optimize sensor structure design and signal processing algorithms to further improve measurement accuracy at low flow rates and meet the needs of refined metrology.

Corrosion resistance and wear-resistant strengthening: Developing new lining and electrode materials to enhance the adaptability of equipment to high solid content and strongly corrosive media, and extending the service life under harsh working conditions.

Low power consumption and self powering: Combining solar energy and battery powered technology, develop a low-power version that is suitable for outdoor scenarios without external power sources (such as river monitoring and remote rural pipeline networks).

Multi parameter integration: Integrating multiple parameter measurement functions such as flow rate, temperature, and pressure to achieve one-stop fluid monitoring, reducing the number of equipment installations and system complexity.

7、 User reviews

Customer of sewage treatment plant: "YST183F-A50XL model from Dalian YisterDN300 pipe section electromagnetic flowmeterAdapting to our factory's inlet pipe network, stable measurement data, smooth integration with online monitoring platform, no need for repeated verification of sewage accounting, and simple maintenance. Cleaning the electrodes every six months is sufficient. ”

Customer of the water supply plant: "It has always been difficult to control the measurement of large-diameter pipelines. After the installation of the YST183F-A50XL equipment from Dalian Yister, the deviation of the total water supply measurement data is small, providing reliable data for pipeline leakage analysis. It has been running for more than a year without any faults. ”

Hospital wastewater treatment customer: "Hospital wastewater contains disinfectants and has a certain degree of corrosiveness. The Dalian Yister YST183F-A50XL corrosion-resistant material version is selected, and the electrode has not had any corrosion problems after two years of use. The flow data is accurate and meets the monitoring requirements of the environmental protection department. ”

Smart Rural Water Customer: "Dalian Yiste's YST183F-A50XL equipment supports remote transmission. We don't have to go to the site to read meters, and we can see the water supply flow of each village on the platform. Malfunctions will also trigger an alarm, greatly reducing maintenance workload and making it very suitable for rural water management. ”

Thermal heating customer: "During the heating season, the hot water flow fluctuates greatly. Dalian Yist's YST183F-A50XL equipment has a fast response speed and can keep up with the flow changes in real time, helping us to accurately allocate heat. The user complaint rate has significantly decreased. ”

8、 Application Cases

Case 1: Flow monitoring project of a municipal sewage treatment plant

Project requirement: The factory processes 100000 tons of sewage per day, with a nominal diameter of 300mm for the inlet pipe network. Accurate measurement of the inlet flow rate is required to provide data for process aeration and dosing control, while also connecting to an environmental protection online monitoring platform.

Application plan: We selected the YST183F-A50XL equipment from Dalian Yister and installed a total of 3 units, which were deployed in the inlet manifold, bioreactor reflux pipe, and outlet manifold respectively. We used corrosion-resistant lining and stainless steel electrodes to adapt to the high solid content and corrosive characteristics of sewage.

Application effect: Measurement accuracy reaches ± 0.5% FS, data is uploaded in real-time to the central control system and environmental protection platform, process control response speed is improved by 30%, pollution accounting data is accurate, and it has passed the acceptance of the environmental protection department.

Case 2: A Smart Rural Water Supply Project

Project requirement: A centralized water supply project covering 5 administrative villages, with a main pipeline of 300mm nominal diameter. The total water supply and branch flow of each village need to be monitored to achieve remote meter reading and leakage warning. Remote sections without external power supply need to be equipped with battery power supply.

Application plan: Install our YST183F-A50XL model and supporting small caliber equipment on the main water supply pipeline and various village branch nodes, using low-power versions, with some nodes powered by solar energy, supporting NB IoT remote communication, and accessing the smart water cloud platform.

Application effect: Real time monitoring and remote control of water supply have been achieved, reducing the leakage rate from 15% to 8%, eliminating the need for manual on-site meter reading, reducing maintenance costs by 60%, and significantly improving the satisfaction of villagers with water use.

Case Three: Wastewater Treatment Project of a Chemical Enterprise

Project requirement: Enterprise chemical wastewater contains acidic and alkaline substances, with strong corrosiveness. The discharge pipe is a nominal diameter 300mm pipeline, and the amount of wastewater needs to be measured and treated to ensure compliance with discharge standards. At the same time, it is suitable for the complex electromagnetic environment in the workshop.

Application plan: Choose our Dalian Yister YST183F-A50XL equipment, equipped with Hastelloy electrodes and PTFE lining, built-in reinforced anti-interference circuit, installed in the outlet pipeline of the wastewater treatment station, and connected to the enterprise's environmental protection control system.

Application effect: It has resisted electromagnetic interference in the workshop, stable measurement data, and meets the standard of corrosion resistance. It has been running for three years without electrode corrosion or signal drift problems, meeting the requirements of environmental protection departments for regular monitoring.

Case 4: Flow Control Project of Heating Network in a Certain City

Project requirement: The main pipeline for urban centralized heating is a 300mm nominal diameter pipe, which needs to monitor the inflow flow of each thermal station to achieve accurate heat distribution and solve the problem of uneven heating. The equipment is required to adapt to the low-temperature environment in winter.

Application plan: Install our Dalian Yister YST183F-A50XL equipment on the inlet manifold of each thermal station, using low-temperature resistant materials, outputting 4-20mA signals to connect with the thermal control system, and providing real-time feedback on flow data.

Application effect: The flow measurement responds quickly, and the heating station can dynamically adjust the heating amount based on the flow data. The temperature uniformity in the heating area is improved, the number of user complaints is reduced by 40%, and the heating energy consumption is reduced by 12%.