-

E-mail

wyldar@wyldar.com

-

Phone

13600256492,18819524003

-

Address

Building 4, No. 224 Chang'an Section, Tai'an Road, Chang'an Town, Dongguan

Dongguan Gaotengda Precision Tools Co., Ltd

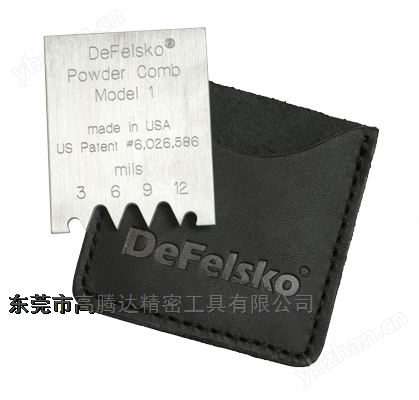

Defelsko dust thickness comb in the United States checks dust thickness before solidification

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

the United StatesDefelskoCheck the dust thickness before the dust thickness comb solidifies

Brand: United StatesDefelsko

Name: Dust Thickness Comb

Purpose: To check the powder thickness before curing to ensure the correct curing film thickness

Before solidification, use a powder comb to check the thickness of the powder to ensure the correct film thickness during the first pass through the production line. Avoid peeling and recoating, as this may lead to adhesion and coating integrity issues.

Suitable for parts of various sizes, shapes, and substrates, such as metal, plastic, wood, glass, etc

When measuring, the supports on both sides of the teeth help to keep the gauge perpendicular to the surface

Precision gauges; The manufacturing tolerance is±5Microns or±0.0002inch

Each instrument is equipped with a protective leather bag

Features:

versatility

Very suitable for quality control

Suitable for parts of various sizes, shapes, and substrates, such as metal, plastic, wood, glass, etc

Easy to carry; Small size, can be placed in a shirt pocket

Can be expressed in micrometers (metric) or (imperial)

quality

When measuring, the supports on both sides of the teeth help to keep the gauge perpendicular to the surface

The sturdy aluminum structure can extend the lifespan of the gauge and control static electricity

Precision gauges; The manufacturing tolerance is±5Microns or±0.0002inch

Each instrument is equipped with a protective leather bag

Easy to operate

1.Insert the powder comb vertically into the dry powder, ensuring that the two supports (end tabs) on both sides of the teeth are firmly pressed against the substrate.

2.Drag the powder comb along the surface of the coated part at least1Centimeters.

3.Remove the powder comb from the surface and inspect the traces left on the powder. The thickness of the powder is between the tooth with the highest number and the next tooth without any markings or powder attachment.

Example75Microns and150Microscopic teeth have lines and powder adheres to them, but225There are no micrometer teeth. The thickness of uncured powder is determined to be150to225Between micrometers. (See above picture)

Note: Most powders solidify to about their dry thickness50%The marks left by the gauge may affect the characteristics of the cured film.

Powder brush model |

height1 |

height2 |

height3 |

height4 |

model1(Microns) |

3 |

6 |

9 |

12 |

model2(Microns) |

10 |

15 |

20 |

25 |

model3(Microns) |

20 |

30 |

40 |

50 |

model4(Microns) |

75 |

150 |

225 |

300 |

model5(Microns) |

250 |

375 |

500 |

625 |

model6(Microns) |

500 |

750 |

1000 |

1250 |