-

E-mail

3585860167@qq.com

-

Phone

18925240236

-

Address

501, Building 6, Longbi Industrial Zone, Longgang District, Shenzhen

Shenzhen Dongri Yingneng Technology Co., Ltd

Description of Smoke Online Monitoring System

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Description of Smoke Online Monitoring System

Composition and Function of Preprocessing System:

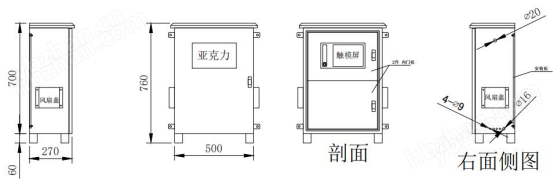

(Configuration dimension diagram)

Description of Smoke Online Monitoring SystemAcceptable pressure, temperature, humidity, flow rate, dust content, and cleanliness to complete its processing function, mainly completing the following tasks:

(1) Sample sampling: Use a vacuum sampling pump or a brushless DC pump to extract the sample gas from the environment such as the flue.

(2) Dust filtration: The tested gas passes through a precision dust filter before entering the sampling pipeline. If it is a high dust environment, an automatic blowback system can be selected.

(3) Cooling treatment: By using sampling probes and sampling pipelines to cool down, gases below 600 ℃ can be processed, and higher temperatures can be customized.

(4) Optional function: Dual stage electronic condensation dehumidification system, which stabilizes the dew point of the gas at 4 ℃ or 5 ℃.

(5) Tar treatment: The sample gas is filtered through a tar filter to remove tar and residual dust.

(6) Gas water separation: After the sample gas is cooled down through the sampling pipeline, free water appears. The gas water separator separates the gas, water, and residual dust, and automatically drains the water.

(7) Secondary filtration: Select according to the humidity level on site and perform secondary water vapor separation.

(8) Heat tracing function: This function is optional, providing heating and insulation to prevent water vapor condensation and partial gas dissolution in water. It also prevents the sampling pipeline from freezing in winter.

(9) Detection and analysis: Real time detection and display of concentration, and transmission of data through signal methods such as 4-20mA/RS485. It can also be wirelessly transmitted through DTU or network to remote servers, environmental protection bureaus, and monitoring stations.

(10) Flow regulation: Control the detection and analysis of gas intake volume.

(11) Gas switching: Switching between the measured gas, standard gas, or air.

(12) Backblowing function: optional, reserved blowback interface. (Backup port)

Outer box size diagram:

Product logistics packaging:

(Weight approximately: 40.28KG)

Collaboration case:

In 2021, the chimney of the * * * * brick factory in Luoyang, Henan Province; Temperature 300 degrees; Excessive dust, equipped with cooling and dust removal, environmental protection bureau detected excessive nitrogen oxides, pre-treatment with reverse blowing, on-site installation diagram.

Customer case of online monitoring and pretreatment system for exhaust gas:

July 2021; Client: Beijing * * * Engineering Co., Ltd; Location: Beijing Science and Technology Innovation Street; According to customer requirements, the on-site networked environmental protection bureau and organic waste gas online monitoring system monitoring software are installed in an external industrial computer to monitor and summarize all gas concentration information and working status information. At the same time, functions such as generating reports, storing data, recording historical data, and networking communication with environmental protection departments are customized according to customer needs.