-

E-mail

549001739@qq.com

-

Phone

13301403246

-

Address

Building 4, Jinhu Square, Jinhu Industrial Park, Jinhu County, Jiangsu Province

Jiangsu Jinhu Huasheng Measuring Instrument Co., Ltd

Differential pressure gauge calibrator

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Differential pressure gauge calibrator

A high-precision and multifunctional standard instrument developed for verifying various differential pressure measuring instruments, with differential pressure measurement, current measurement, 24VDC power output, and pressure switch testing functions. It can be combined with a handheld pressure pump to achieve pressure generation and measurement integration, thus realizing on-site calibration of differential pressure gauges, differential pressure (pressure) transmitters, pressure switches, ordinary (precision) pressure gauges and other instruments.

Differential pressure gauge calibrator

I. Overview

1. As a multifunctional instrument, it can measure ± 25mADC current or ± 50VDC voltage while measuring pressure. The pressure switch is tested and the pressure switch value is automatically recorded. It has a 24VD output and can be used as a power supply for 4-20mA two-wire transmitters. It also has the function of recording large and small values.

2. Using a 24 bit high-performance A/D converter combined with a high-performance microprocessor to continuously adjust the various performance and technical indicators of the instrument, ensuring that the instrument can be used over a wide temperature range for a long time without affecting its accuracy.

3. Low power consumption, the battery adopts imported high-energy lithium batteries, with an imported aluminum alloy casing, beautiful appearance, sturdy and durable, and strong anti-interference ability.

4. Intelligent charging, with automatic shutdown and protection functions for battery overcharging and undervoltage. The low-power shutdown protection function protects the instrument from battery energy damage when not in use for a long time, ensuring the longevity of the battery,

5. Ultra high resolution 1:1000000, continuous display without broken codes or text jumping phenomenon.

6. Adopting thin film panels and imported tactile switches, the style is novel and the button life is long.

7. Backlit LCD multi-channel display with low power consumption and long lifespan.

8. The digital calibration of pressure, current, and voltage does not require any hardware adjustment, and can be directly operated on the panel to calibrate zero and full range.

9. Built in six digit high-precision DC digital voltage and current meter.

10. Equipped with RS-232 or RS-485 interfaces, it can communicate with the upper computer, transmit real-time measurement data to the calibration software, record data, automatically generate tables, calculate errors, and store and print calibration data. Can calibrate pressure transmitters, pointer pressure gauges, pressure switches (pressure controllers), etc.

2、 Purpose:

In addition to being used as a high-precision calibration standard (meter), it can also be used as an on-site calibration instrument, widely used in metallurgy, petroleum, chemical, power, natural gas, metrology, and scientific research departments.

3、 Working principle

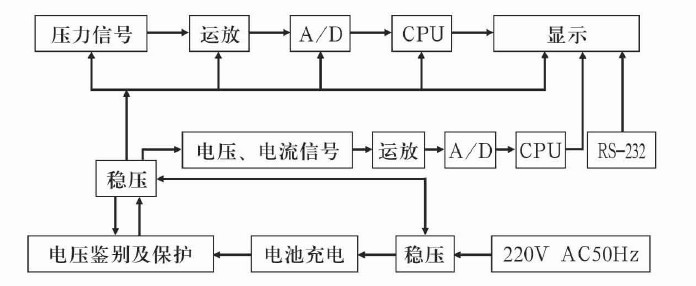

1. Principle diagram

2. Working principle

a、 Pressure: The measured medium is applied to a solid-state (silicon diaphragm) sensor from a pressure tube. When the pressure changes, the resistance of the diffused silicon diaphragm changes under the pressure resistance effect. This change is detected as an electrical signal and converted into a voltage signal proportional to the pressure through a circuit. The signal is converted into a digital signal by a 24 bit analog-to-digital converter, processed by a microprocessor, and displayed on an LCD display as the numerical value of the measured medium pressure.

b、 Current and Voltage: When a random pair of probes are inserted into the corresponding socket on the instrument panel, the instrument can be turned on and switched to the current or voltage mode for measurement. The measured data is collected by a 24 bit A/D converter and sent to a microprocessor for linear, temperature, and full-scale processing. The measured value is then displayed on the LCD screen.

4、 Technical instructions

1. Pressure range: -60~60kPa (see attached table for range selection). Multiple intelligent digital pressure modules can also be selected, with unlimited quantity and range, and easy automatic recognition and use (see attached table for module selection). Optional gauge pressure, absolute pressure, or differential pressure measurement can be used in combination with manual pumps or pressure calibrators to calibrate pressure transmitters, spring tube pressure gauges, pressure switches, etc

2. Resolution: Pressure: Min 0.01Pa (determined by range)

Current: 0.1 μ A Voltage: 0.1mV

3. Current measurement range: ± 25.000mA, voltage measurement range: ± 50.0000V

4. DC power output: 24VDC ± 10%, high load current 50mA

5. Accuracy: Pressure: 0.1% F • S 0.05% F • S 0.02% F • S

Voltage and current: ± (0.01% R.D+0.005% F • S)

6. Temperature compensation range: 0-50 ° C, ensuring instrument accuracy within the range of 0-50 ° C

7. DC working time: ≥ 80 hours, depending on the working conditions

8. Display: LCD backlit LCD screen, pressure and electrical signal buttons can be selected for 5-digit or 6-digit display

9. Overload capacity: 1.2-1.5 times the upper range limit

10. Dimensions: Instrument outer diameter 155mm, thickness 47mm (sensor nozzle outer diameter 58mm, length 68mm)

11. Weight: 1000g, working temperature: 0-50 ° C, relative humidity: ≤ 80% RH

12. Power supply: 3.7V/4000mAh lithium battery, charging voltage 5V, with battery level display function, easy to understand battery usage

13. Pressure medium: The pressure medium can only be non corrosive dry gas

5、 Precautions

1. When the instrument is not in use, the power should be turned off. If it is not in use for a long time, it should be discharged and charged once every three months.

2. The instrument has sufficient overload capacity, but do not overload it severely, otherwise it will cause damage to the instrument sensor and render the instrument unusable.

3. Instrument sensors belong to high-precision products, and the surface of the silicon diaphragm should not collide with solids, otherwise it will damage the sensor.

4. Without professional testing skills and equipment, do not open the chassis for maintenance, and do not adjust internal components or replace materials, otherwise the reliability of the instrument cannot be guaranteed.