-

E-mail

1097698793@qq.com

-

Phone

18915180705

-

Address

No. 286 Tongtai Avenue, Jinhu Economic Development Zone, Jiangsu Province

Jiangsu Runyi Instrument Co., Ltd

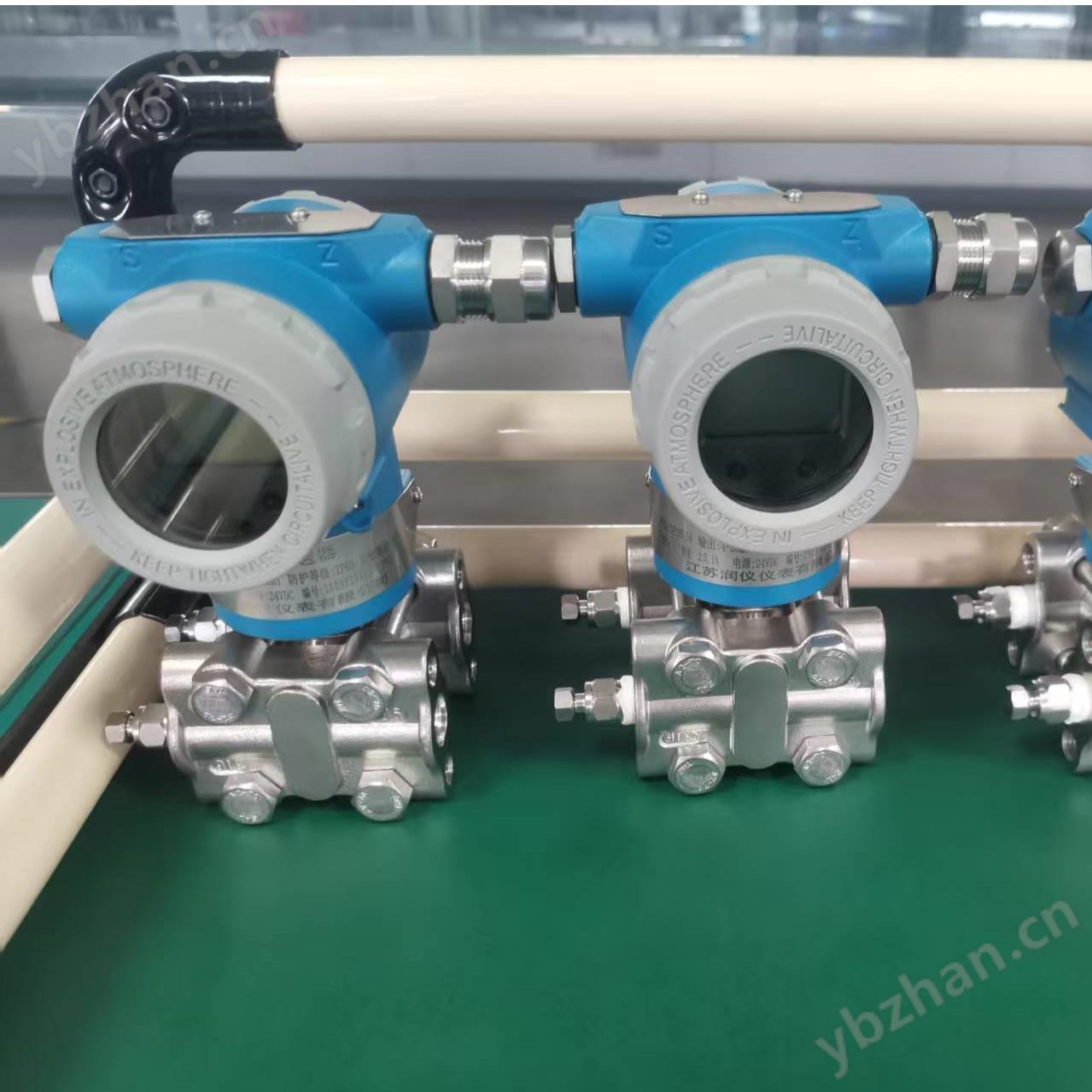

Differential pressure transmitter for measuring flue gas

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Product Name:Differential pressure transmitter for measuring flue gas

Product Model: JSRY-PB/DP3SJ4

Manufacturer:Jiangsu Runyi Instrument Co., Ltd

Product definition:

Differential pressure transmitter for measuring flue gasIt is suitable for measuring the liquid level, density, and pressure of liquids, gases, or vapors, and then converting them into4~20mA DCSignal output. Intelligent and compatibleHARTThe handheld devices communicate with each other to set, monitor, or form an on-site monitoring system with the upper computer. SK1151/3351DPOn site adjustable intelligent differential pressure transmitter is a transmitter product that can be operated without a manual controller and can achieve on-site zero adjustment, configuration, and other operations through button pressing.

Product Technical Parameters:

Target audience: Differential pressure level transmitter for liquids and liquid mixed vapors.

Measurement range: 0-25Pa to 40MPa

Output signal: 4-20mA DC, intelligent type supports Hart protocol communication (special orders can be ordered with four wire 220V AC power supply 0-10mA DC output)

Power supply: Ordinary transmitter 12-45V DC, explosion-proof transmitter 24V DC

Load characteristics: related to the power supply, with load capacity at a certain power supply voltage. The relationship between load impedance RL and power supply voltage Vs is: RL ≤ 50 (Vs-12)

Indicator: An ammeter can be used for on-site output indication, and our company can provide linear indication 0-100% and square root indication 0-100% meter heads; 3 1/2 digit LCD digital display table, with 13mm high output displayed as a percentage.

Explosion proof: Our factory produces two types of explosion-proof transmitters: a. Explosion proof dIIBT4; b、 Intrinsically safe iaIICT6

Range and zero position: externally continuously adjustable, intelligent models require Hart operator/software or in shell adjustment

Positive and negative migration: The maximum positive migration of the differential pressure transmitter is 500%, and the maximum negative migration is 600%;

The range ratio of the intelligent transmitter is 100:1

Working temperature: Electronic components: -29~+93 ℃ (ordinary type transmitter)

-20~+60 ℃ (explosion-proof transmitter)

Measuring components: -40~+104 ℃ (filled with silicone oil)

LCD display: -20 to+70 ℃

Environmental humidity: 0-100% RH.

Storage temperature: -40 to+100 ℃

Overload pressure: not exceeding 1.15 times the maximum static pressure (see selection table for maximum static pressure)

Volume change: < 0.16cm3

Damping time: continuously adjustable within 0.2-1.67 seconds (0.1-16 seconds for intelligent models), slightly longer for micro, low differential pressure, and flange transmitters; Damping time is the step response.

Start time: 2 seconds, no preheating required.

Product selection method:

JSRY-PB/DP |

Differential pressure transmitter |

|||||||

code |

measurement range |

|||||||

3 |

0-0.6~6Kpa |

|||||||

4 |

0-4~40Kpa |

|||||||

5 |

0-40~250Kpa |

|||||||

6 |

0-0.16~1.0Mpa |

|||||||

7 |

0-0.4~2.0Mpa |

|||||||

8 |

0-1.6~10.0Mpa |

|||||||

code |

output |

|||||||

E |

4-20mA |

|||||||

S |

intelligent type |

|||||||

code name |

structural material |

|||||||

Flanges and fittings |

exhaust/drain valve |

Isolation membrane |

Fill with liquid |

|||||

22 |

316 stainless steel |

316 stainless steel |

316 stainless steel |

silicone oil |

||||

23 |

316 stainless steel |

316 stainless steel |

HastelloyC |

|||||

24 |

316 stainless steel |

316 stainless steel |

Monel |

|||||

25 |

316 stainless steel |

316 stainless steel |

Tantalum |

|||||

33 |

HastelloyC |

HastelloyC |

HastelloyC |

|||||

35 |

HastelloyC |

HastelloyC |

Tantalum |

|||||

44 |

Monel |

Monel |

Monel |

|||||

code name |

Maximum work pressureMPa |

|||||||

B- |

4 |

|||||||

C- |

10 |

|||||||

D- |

14 |

|||||||

code |

option |

|||||||

M1 |

0-100% linear indicator table |

|||||||

M2 |

LED display table |

|||||||

M3 |

LCD display table |

|||||||

B1 |

Pipe bending bracket |

|||||||

B2 |

Board mounted bending bracket |

|||||||

B3 |

Pipe mounted flat bracket |

|||||||

D1 |

The side relief valve is located at the upper part of the pressure chamber |

|||||||

D2 |

The side relief valve is located at the lower part of the pressure chamber |

|||||||

No note |

1/2NPT taper pipe threaded joint |

|||||||

C0 |

1/2-14NPT spinal threaded joint |

|||||||

C1 |

?1/2-14NPTWelding pressure pipe at the rear of the pressure jointF14 |

|||||||

C2 |

T-shaped threaded jointM20×1.5, with rear weldingF14Spherical cone connector of pressure pipe |

|||||||

d |

Explosion proof typedIIBT4 |

|||||||

i |

Intrinsic safety typeiaⅡCT6 |

|||||||

J |

Flow Transmitter4-20mAFounder's output |

|||||||

s |

Stainless steel three valve group |

|||||||