-

E-mail

wt50120@126.com

-

Phone

13868628633

-

Address

Dongou Industrial Park, Dongou Street, Yongjia County

Zhejiang Yangtze River Pump Industry Co., Ltd

Direct sales ZCQ32-25-115 stainless steel magnetic pump

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

ZCQ magnetic pump; zcqmagnetic drive pump

Product Overview

ZCQ type self-priming magnetic pump (hereinafter referred to as self-priming pump) is a new product that has been developed based on the CQ type magnetic pump according to the requirements of many users, and has been successfully researched and tested by our engineering and technical personnel. Its performance has reached the advanced level of similar products in the 1990s. This pump replaces dynamic seals with static seals, keeping the flow components of the pump in a sealed state, solving the problems of running, emitting, dripping, and leaking that cannot be avoided by other pump mechanical seals. The materials of the pump body and flow components are made of corrosion-resistant stainless steel, steel jade ceramics, PTFE stone and other materials, which not only have the function of CQ type magnetic drive pump, but also integrate self-priming, without the need for bottom valves and drainage water. The self-priming height is 4 meters.

ZCQ typeSelf suction magnetic pumpMain Features

The ZCQ magnetic self-priming pump has a compact structure, beautiful appearance, small volume, low noise, reliable operation, and easy maintenance. It can be widely used in petroleum, chemical, pharmaceutical, electroplating, printing and dyeing, food, scientific research and other units to pump acids, alkalis, oils, rare and valuable liquids, venoms, volatile liquids, as well as supporting circulating water equipment, especially for the pumping of easily leaking, flammable and explosive liquids. Therefore, it has a wide range of uses, and we sincerely recommend this product to users.

ZCQ typeSelf suction magnetic pumpModel significance

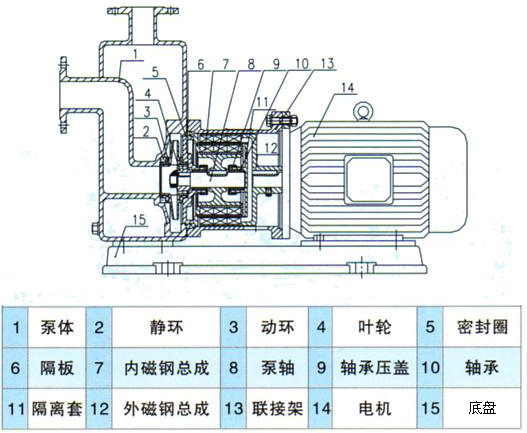

ZCQ typeSelf suction magnetic pumpstructural diagram

ZCQ typeSelf suction magnetic pumpPerformance Parameter Table

| model | Flow rate (m3/h) | Head (m) | Motor power (kw) | Suction distance (m) |

| 20-12-110 | 3 | 12 | 0.37 | 4 |

| 25-20-115 | 6.6 | 15 | 1.1 | 4 |

| 32-25-115 | 6.6 | 15 | 1.1 | 4 |

| 32-25-145 | 6.6 | 25 | 1.1 | 4 |

| 40-32-132 | 10.8 | 20 | 2.2 | 4 |

| 40-32-160 | 12 | 32 | 4 | 4 |

| 50-40-145 | 14.4 | 25 | 4 | 4 |

| 50-40-160 | 13.2 | 32 | 4 | 4 |

| 65-50-145 | 16.8 | 25 | 5.5 | 4 |

| 65-50-160 | 27 | 32 | 7.5 | 4 |

| 80-65-160 | 51 | 32 | 15 | 4 |

| 80-50-200 | 51 | 50 | 22 | 4 |

| 80-50-250 | 51 | 80 | 37 | 4 |

| 100-80-160 | 100 | 32 | 22 | 4 |

| 100-65-200 | 100 | 50 | 37 | 4 |

| 100-65-250 | 100 | 80 | 55 | 4 |

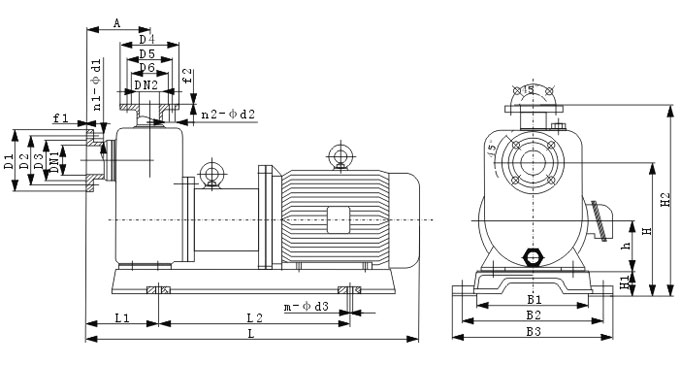

ZCQ typeSelf suction magnetic pumpInstallation dimension drawing

| model | A | B1 | B2 | B3 | h | H | H1 | H2 | L | L1 | L2 | m-φd3 |

| Zcq 25 - 20 - 115 | 132 | 170 | 216 | 240 | 80 | 290 | 70 | 400 | 410 | 150 | 300 | 4-φ11.5 |

| Zcq 32 - 25 - 115 | 132 | 170 | 216 | 240 | 80 | 290 | 70 | 400 | 410 | 150 | 300 | 4-φ11.5 |

| Zcq 32 - 25 - 145 | 132 | 170 | 216 | 240 | 80 | 290 | 70 | 400 | 410 | 150 | 300 | 4-φ11.5 |

| Zcq 40 - 32 - 132 | 140 | 170 | 216 | 240 | 90 | 290 | 70 | 400 | 640 | 175 | 360 | 4-φ11.5 |

| Zcq 40 - 32 - 160 | 145 | 235 | 290 | 330 | 112 | 315 | 80 | 415 | 705 | 175 | 400 | 4-φ13.5 |

| Zcq 50 - 32 - 125 | 145 | 235 | 290 | 330 | 112 | 350 | 80 | 480 | 790 | 180 | 420 | 4-φ13.5 |

| Zcq 50 - 32 - 160 | 150 | 235 | 290 | 330 | 112 | 350 | 80 | 480 | 790 | 180 | 420 | 4-φ13.5 |

| Zcq 50 - 32 - 200 | 150 | 270 | 316 | 350 | 132 | 420 | 82 | 615 | 870 | 210 | 500 | 4-φ13.5 |

| Zcq 65 - 50 - 125 | 180 | 270 | 316 | 350 | 132 | 400 | 82 | 590 | 830 | 210 | 450 | 4-φ13.5 |

| Zcq 65 - 50 - 160 | 180 | 270 | 316 | 350 | 132 | 400 | 82 | 590 | 870 | 210 | 500 | 4-φ13.5 |

| Zcq 65 - 40 - 200 | 180 | 340 | 400 | 440 | 160 | 446 | 96 | 650 | 1040 | 230 | 610 | 4-φ18.5 |

| Zcq 80 - 65 - 125 | 200 | 270 | 316 | 350 | 132 | 446 | 82 | 630 | 960 | 230 | 520 | 4-φ13.5 |

| Zcq 80 - 65 - 160 | 200 | 340 | 400 | 440 | 160 | 446 | 96 | 630 | 1060 | 230 | 610 | 4-φ18.5 |

| Zcq 80 - 50 - 200 | 200 | 340 | 400 | 440 | 180 | 470 | 96 | 680 | 1090 | 230 | 610 | 4-φ18.5 |

| Zcq 80 - 50 - 250 | 200 | 375 | 460 | 510 | 220 | 510 | 100 | 760 | 1250 | 280 | 700 | 4-φ28 |

| Zcq 100 - 80 - 160 | 240 | 340 | 400 | 440 | 180 | 465 | 96 | 650 | 1090 | 250 | 700 | 4-φ24 |

| Zcq 100 - 65 - 200 | 240 | 375 | 460 | 510 | 220 | 510 | 100 | 760 | 1250 | 280 | 700 | 4-φ28 |

| Zcq 100 - 65 - 250 | 240 | 435 | 520 | 570 | 280 | 620 | 120 | 860 | 1410 | 300 | 880 | 4-φ28 |

ZCQ typeSelf suction magnetic pumpperformance curve graph

ZCQ typeSelf suction magnetic pumpDevice Example

Installation and use

1. After opening the box, check the pump nameplate and verify whether the main parameters of the self-priming pump product are consistent with the usage requirements.

2. Self priming pumps should be installed horizontally, and the pump body should not bear the weight of the pipeline.

3. The pump and pipeline should maintain good sealing.

4. Before using the pump, it should be checked that the motor fan blades rotate flexibly, without stopping or abnormal noise, and that all fasteners are firm.

5. Unscrew the water adding bolt above the pump, add less than two-thirds of the pump body volume of the stored liquid, and tighten the bolt.

6. Connect the power supply and try to turn it on. From the motor end, check if the operation matches the pump direction mark *.

7. Before the pump stops working, close the discharge valve first, then turn off the power, and finally close the suction pipe valve.

ZCQ typeSelf suction magnetic pumpPrecautions for use

1. Due to the fact that the cooling and lubrication of magnetic pump bearings rely on the medium being transported, idle running is prohibited, while avoiding spatiotemporal load running caused by restarting after a power outage during operation.

2. If the conveyed medium contains solid particles, a filter screen should be added to the pump inlet; if it contains ferromagnetic particles, a magnetic filter should be added.

3. The ambient temperature of the pump during use should be less than 40 ℃, and the temperature rise of the motor should not exceed 75 ℃.

4. The conveyed medium and its temperature should be within the allowable range of the pump material (see attached table for details) The operating temperature of the metal pump is < 100 ℃, and the specific gravity of the conveyed medium is ≤ 1.3; When the specific gravity of the medium is less than 1.3, it will affect the technical performance.

5. For media that are prone to precipitation and crystallization during transportation, they should be cleaned promptly after use to drain the accumulated liquid in the pump.

6. After 500 hours of operation of the self-priming pump, the wear of the bearings and end face dynamic rings should be inspected. If the gap between the bearings and the shaft sleeve is greater than 0.5-1mm and the impeller moves 0.5-2mm in the axial direction, the bearings and axial dynamic rings should be replaced.

ZCQ typeSelf suction magnetic pumpCause and solution of malfunction

failure mode |

root cause |

exclusion method |

Self suction magnetic pump does not produce water |

a、 Reverse rotation of water pump |

Change the motor wiring |

b、 Air leakage in the inlet pipeline |

Eliminate air leakage |

|

c、 Insufficient water storage in the pump chamber |

Increase storage capacity |

|

d、 The voltage is too high, causing the coupling to slip during startup |

Adjust the positive voltage |

|

e、 The suction distance is too high |

Lower the installation position of sand |

|

f、 The valve is not open |

Correct or modify the valve |

|

Insufficient flow rate of self-priming magnetic pump |

a、 The suction pipe diameter is too small or clogged |

Replace the inlet pipe |

b、 Impeller channel blockage |

Clean the impeller |

|

c、 Head too high |

Turn up the outlet valve |

|

d、 Insufficient rotational speed |

Restore rated speed |

|

The head of the self-priming magnetic pump is too low |

a、 excessive traffic |

Turn down the water outlet valve |

b、 The speed is too low |

Restore rated speed |

|

The self-priming magnetic pump has too much noise |

a、 Severe wear of the shaft |

Replace the pump shaft |

b、 Severe wear of the shaft sleeve |

Replace the shaft sleeve |

|

c、 Drive the magnetic steel cup to contact the isolation sleeve |

Dismantle the pump head and reassemble it |

|

d、 Grinding of sealing ring and impeller |

Replace the thrust ring and sealing ring |

|

Self suction magnetic pump leakage |

O-ring damaged |

Replace the O-ring seal |

|

| |

| CQ explosion-proof stainless steel magnetic pump | |

| |

| CQB Explosion proof Magnetic Pump | Magnetic Chemical Pump | |

| |

| CQ type magnetic drive pump | |

| |

| CQB-F Fluoroplastic Magnetic Pump | Explosion proof Fluoroplastic Alloy Magnetic Pump | |

| |

| CQB-G explosion-proof high-temperature insulation magnetic pump | |

| Related articles |

|