-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

Domestic three coordinate scanning measuring machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Zhongtu InstrumentDomestic three coordinate scanning measuring machineWith independent research and development of core technologies, full scene adaptation capabilities, and practical application data, whether you need batch testing to improve efficiency or precise measurement of precision parts, Zhongtu Instrument can provide a dual solution of precision standards and cost optimization.

1、 Independent research and development of core technologies

The measurement and control system can choose different configurations according to customer needs.

1. Controller - Alpha Series Controller for Zhongtu Instrument

The Alpha series controller is a three coordinate controller independently developed by Zhongtu Instrument. Its performance characteristics include:

(1) Fully closed-loop DC servo motor drive control technology, with excellent servo following control capability;

(2) Solid state electronic switch design, without high-power relays, with smaller volume and impulse current, higher reliability;

(3) Synchronous PWM control technology and common mode suppression design result in fast loop response, high driving efficiency, and low heat generation;

(4) Microsecond level speed forward-looking trajectory planning algorithm, achieving efficient smooth motion and high spatial motion repeatability;

(5) The controller complies with the I++standard and is compatible with mainstream measurement software on the market.

2. Measuring Seat

(1) ACH100T fully automatic rotating measuring seat

Performance characteristics:

·The measuring seat can achieve motion of A angle 0-105 ° and B angle -180 ° -+180 °;

·The measuring seat adopts precise 6-point positioning to achieve high positioning accuracy of the measuring seat;

·Key components are made of composite materials and high-strength materials;

·The measuring seat ensures safe use through dynamic and static anti-collision design.

(2) ACH100T-5 fully automatic rotating measuring seat

Performance characteristics:

·The measuring seat can achieve motion of A angle 0-115 ° and B angle -180 ° -+180 °;

·The measuring seat adopts precise 6-point positioning to achieve high positioning accuracy of the measuring seat;

·Key components are made of composite materials and high-strength materials;

·The measuring seat ensures safe use through dynamic and static anti-collision design.

3. Measuring head

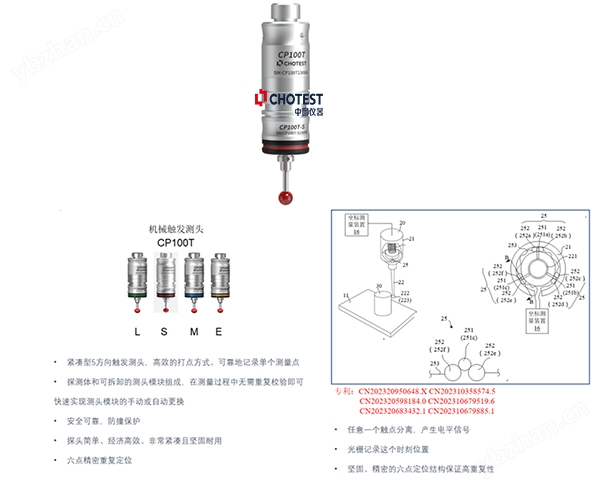

(1) CP100T triggers probe

The CP100T trigger probe is a mechanical trigger probe independently developed by Zhongtu Instrument. It can trigger force in 5 spatial directions with high accuracy and good stability, and its performance is superior to imported probes of the same type.

Components: The measuring head is divided into two parts: the measuring head body and the suction cup, both of which have magnetic suction surfaces. There are four types of suction cups: CP100T-L (low load), CP100T-S (standard load), CP100T-M (medium load), and CP100T-E (high load).

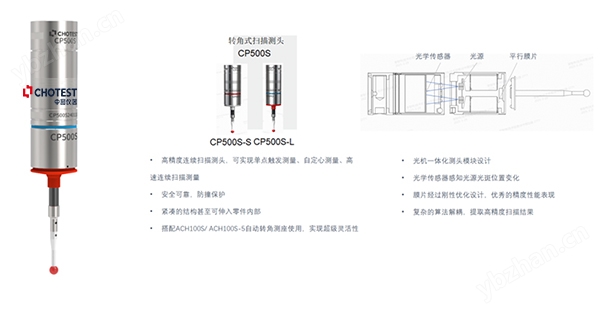

(2) CP500S scanning probe

The CP500S scanning probe adopts a high-resolution grating system with a system resolution of less than 0.1um, which enables the measuring machine to quickly collect a large number of points, ensuring precise positioning and high repeatability of the machine, thus achieving the purpose of detection and digitization. This probe can achieve continuous scanning on the surface of the workpiece, mainly used for the detection of curved and curved parts, with high accuracy and fast speed.

Components: CP500S scanning probe+CP500S-S/L scanning module+probe suction cup. Users can choose any one of the two scanning modules (capable of installing M3 probes with lengths ranging from 20mm to 230mm).

4. Measurement software

Power DMIS is a three coordinate measurement and analysis software independently developed by Zhongtu Instrument, with independently controllable core technology. This software supports DMIS and I++standard protocols, and has passed the German PTB dual certification (least squares method and minimum area method).

Performance characteristics:

·The interface is simple and friendly, with strong interactivity and clear and easy to understand functional modules;

·Strong functionality;

·Compatibility and scalability to meet diverse measurement needs;

·SPC statistical analysis can be performed on measurement data.

2、 Ability to adapt to the entire scene

Flexible configuration, customized according to needs, reducing investment costs.

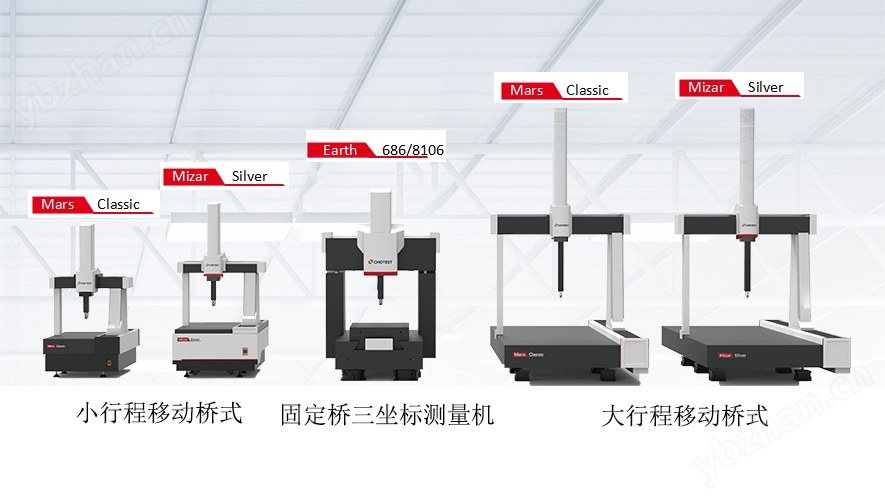

1. Full coverage of multiple models

(1) Small stroke mobile bridge (Mars/Mizar series): Suitable for small and medium-sized parts, with a load-bearing capacity of 600-1200kg and outstanding cost-effectiveness.

(2) Fixed bridge models (Earth series): designed for large precision components, with a load-bearing capacity of up to 500kg and a long-term stability improvement of 30%.

2. Modular selection

(1) The basic configuration meets the requirements of routine testing, and optional accessories such as a refrigerated dryer (extending equipment life by 2 years) and an air flotation turntable (adding polyhedral measurement function) can be provided.

(2) The software supports free upgrades and can be extended with 3D scanning and GD&T advanced analysis functions in the future, without the need for additional device replacement.

3、 Data Empowerment

1. The measurement accuracy is MPEE ≤ (1.5+L/333) μ m (L is the measurement length, unit: mm), the repeatability accuracy is ≤ 0.4 μ m, and even subtle size differences can be accurately captured.

2. Running continuously for 24 hours without drift, with repeatability error controlled within ± 0.35 μ m, helping enterprises reduce quality rework costs by 15% -20%.

3. The scanning probe collects 1000 surface points per second, which increases the efficiency of measuring complex surfaces by 30% compared to traditional equipment and significantly shortens the detection cycle.

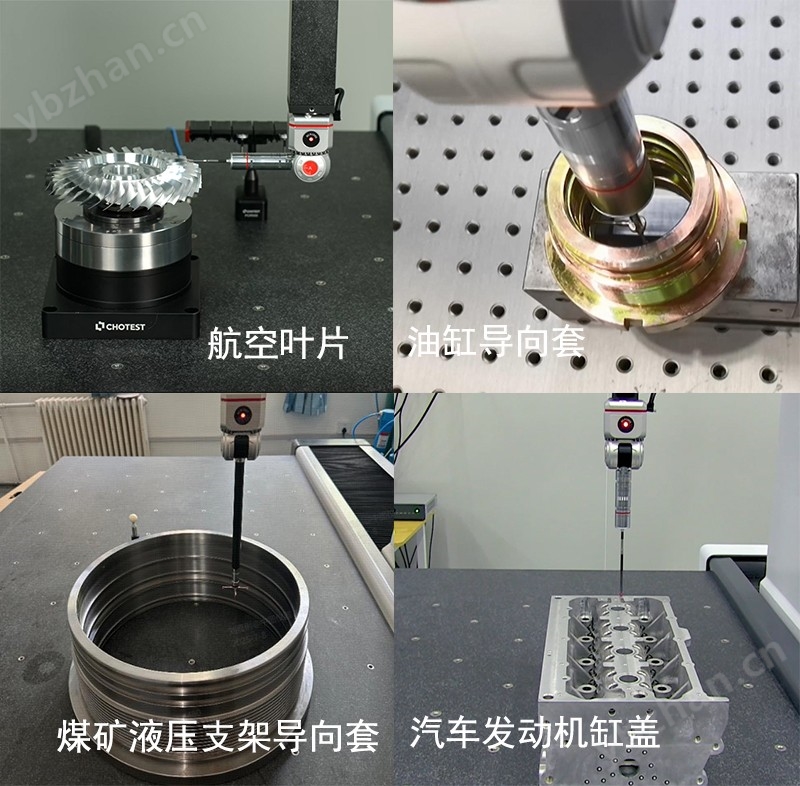

4、 Application Cases

In the fiercely competitive manufacturing industry, micrometer level measurement accuracy, 30% efficiency improvement, and 15% -20% cost savings are the core demands for enterprises to choose testing equipment. Click on 'Consultation' to get it for free! Let data speak for itself, empower production with strength - Zhongtu InstrumentDomestic three coordinate scanning measuring machineHelp you seize the advantage of precision in industry competition!

Note: Product parameters may be updated in real-time based on technological upgrades, and the latest configuration shall prevail. For details, please consult customer service for complete information.