-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Dongguan electric constant temperature blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Electric constant temperature blast drying oven as a laboratory and industrial production toolcrucialThe core function of the equipment is to achieve uniform drying and constant temperature treatment of materials through electric heating and forced hot air circulation. In Dongguan, a region where manufacturing and scientific research activities are active, such equipment is widely used in multiple fields. This article will explore its working principle, core advantages, and typical application scenarios, and analyze them based on actual needsDongguan electric constant temperature blast drying ovenTechnical value.

1、 Working principle: How to achieve precise temperature control through hot air circulation?

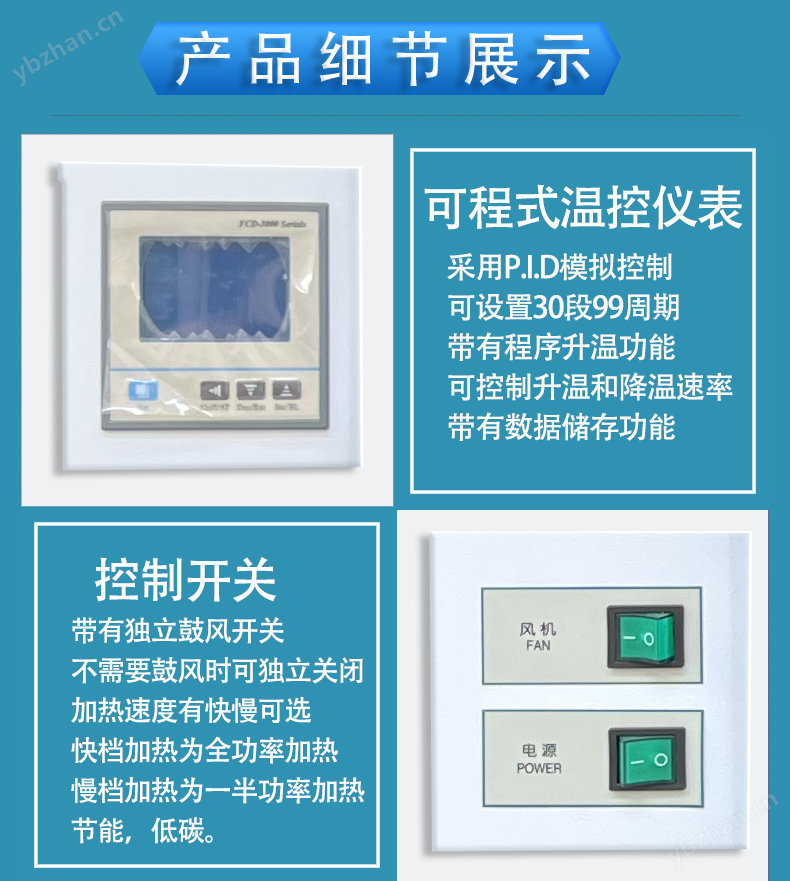

The core of an electric constant temperature blast drying oven lies in the combination of "hot air circulation" and "intelligent temperature control". The operation process is as follows:

Electric heating stageThe built-in electric heating tube heats the air to the set temperature.

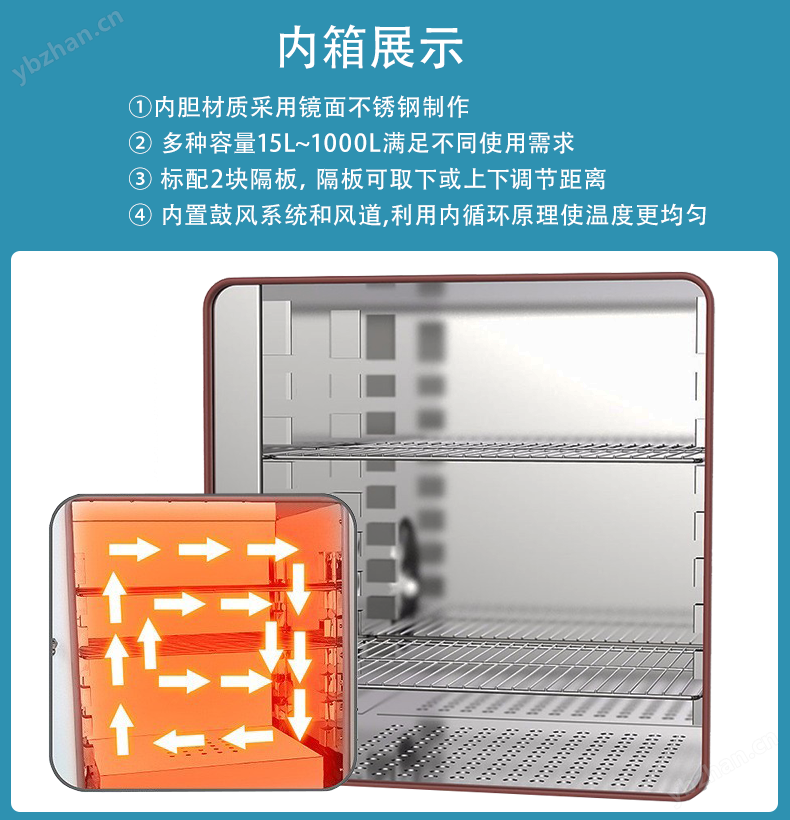

forced convectionThe blower motor drives the fan to evenly blow hot air through the air duct towards the material area, forming a circulating airflow.

temperature feedbackReal time monitoring of the temperature inside the box through sensors, combined with a PID temperature control system to dynamically adjust the heating power, ensuring that the temperature fluctuation range is controlled within ± 0.5 ℃.

questionWhy is hot air circulation more suitable for drying needs than natural convection?

The answer lies in the fact that hot air circulation can accelerate heat transfer, reduce local temperature differences, and is particularly suitable for scenarios that require high uniformity, such as electronic component baking.

2、 Core advantage: Why choose a constant temperature blast drying oven?

temperature uniformity

Through multi-layer air duct design and spiral stirring blades, hot air forms a three-dimensional circulation inside the box, avoiding the common "upper and lower temperature difference" in traditional equipment.

comparative experimentA laboratory test showed that the temperature uniformity of a constant temperature blast drying oven is about 40% higher than that of a natural convection device.

High precision temperature control

Adopting a binocular temperature control system and digital sensors, the temperature resolution can reach 0.1 ℃, meeting the requirements of precision experiments.

Application scenario casesIn the semiconductor packaging process, the curing of adhesives needs to be strictly controlled within ± 1 ℃, and this equipment can stably achieve the goal.

Security protection design

Multiple safety mechanisms such as over temperature alarm, automatic pressure relief, and anti scald protective cover reduce operational risks.

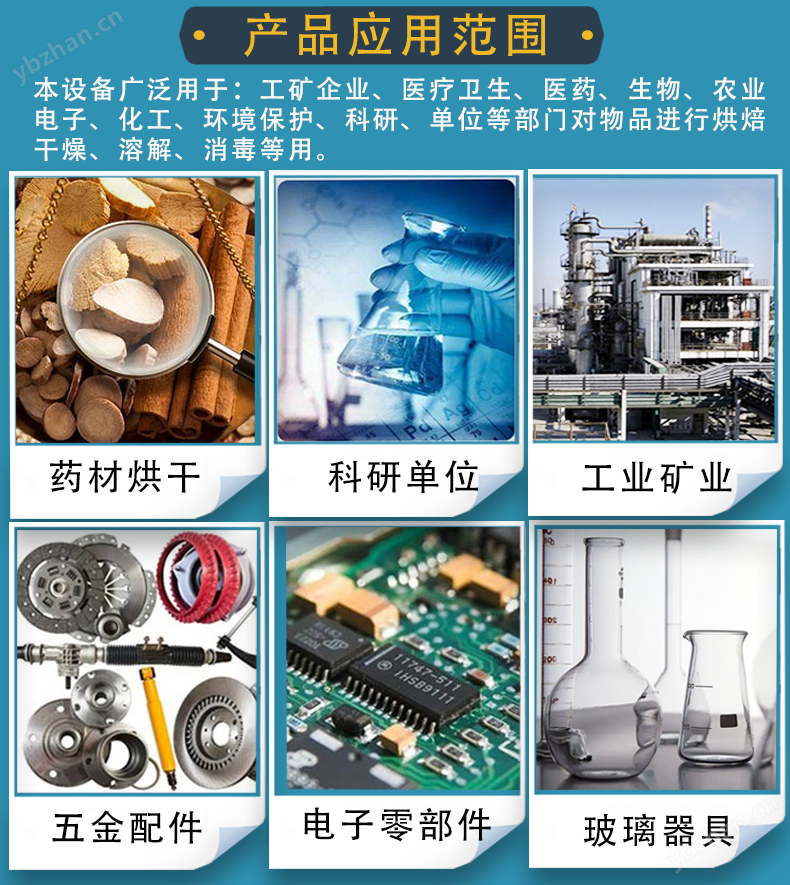

3、 Typical application scenario: Multi functional adaptation from laboratory to factory

| industry | processing object | Equipment advantages |

|---|---|---|

| laboratory | Glassware, experimental samples | Quick drying to avoid cross contamination; Support low-temperature drying (such as wax melting) |

| food industry | Dehydration and moisture detection of fruits and vegetables | Meets the requirements of the national standard drying method, with traceable data |

| electronics manufacturing | Circuit board, semiconductor materials | Prevent oxidation caused by moisture and support program temperature control |

| Agricultural research | Seed moisture control | Simulating natural drying conditions to improve the accuracy of germination rate research |

questionHow does a drying oven ensure the quality of battery cells in the production of new energy batteries?

The answer lies in its high-temperature vacuum assist function, which can quickly remove trace amounts of moisture from the battery cells, avoiding the risk of short circuits caused by moisture in subsequent processes.

4、 Application characteristics of Dongguan region: equipment selection from the perspective of industrial demand

As a manufacturing hub, Dongguan needs to consider both efficiency and cost when selecting equipment

electronics industryTend to choose models that support programmed temperature control to meet the temperature curve requirements of different process stages.

Food testing institutionsPay attention to the clean design of equipment (such as stainless steel liner) and rapid heating ability.

research institutionsPreference for multifunctional models, such as those with observation windows and support for timed operations.

5、 Maintenance and precautions: key to extending equipment lifespan

regular cleaningTo avoid dust accumulation affecting the efficiency of hot air circulation, especially in the areas of air ducts and heating pipes.

Calibration verificationAccording to JJF 1101-2019 standard, regularly calibrate temperature sensors to ensure data reliability.

safe operationIt is strictly prohibited to put flammable and explosive materials, and ensure that the grounding wire is effectively connected.

Conclusion

Dongguan electric constant temperature blast drying ovenWith its precise temperature control, efficient drying, and wide applicability, it has become a fundamental equipment in the industrial and scientific research fields in Dongguan and even across the country. With the iteration of technology, such as the popularization of double-layer insulation structure and intelligent parameter memory function, equipment performance has been further optimized, providing more stable technical support for various industries. In the process of selection and use, it is necessary to combine specific scenario requirements and fully leverage their value.