-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Electronic component electric heating constant temperature blower drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

In the electronic manufacturing industry, the drying process of materials is a key link to ensure product quality. The electric constant temperature blast drying oven has become an important equipment for electronic component processing, packaging, and testing due to its precise temperature control and efficient thermal cycling capability. This article will analyze and explore the technical principles, core advantages, and typical application scenariosElectronic component electric heating constant temperature blower drying ovenThe actual value in the electronics industry.

1、 Working principle and key technologies

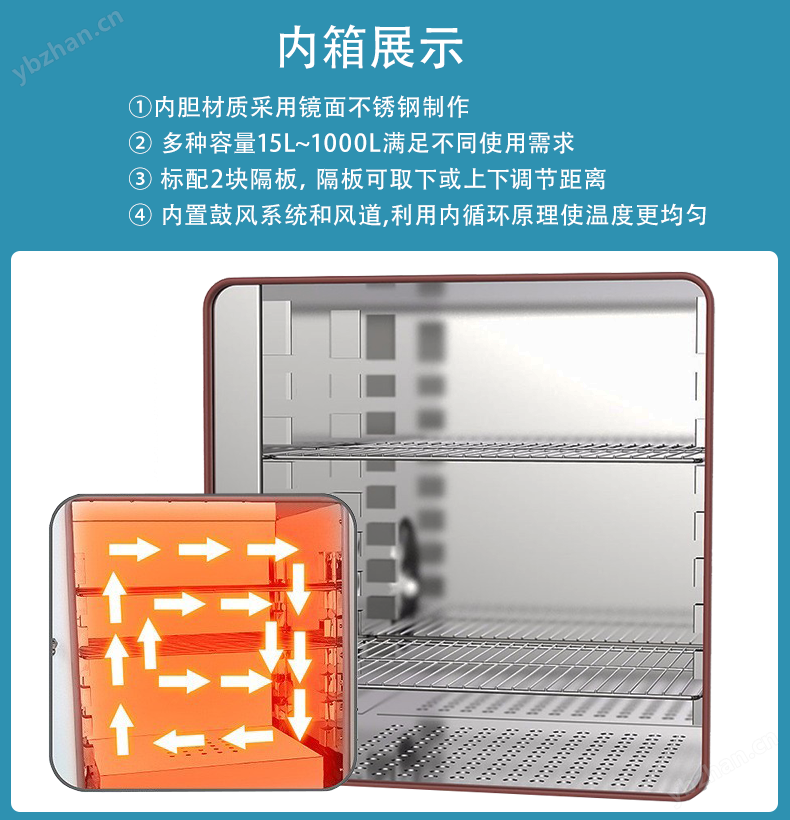

The electric constant temperature blast drying oven generates heat energy through electric heating elements (such as electric heating tubes), combined with a forced air blowing system to form a uniform hot air circulation. Its core lies inStability of temperature control systemandUniformity of hot air distribution.

Technical Key Points Analysis:

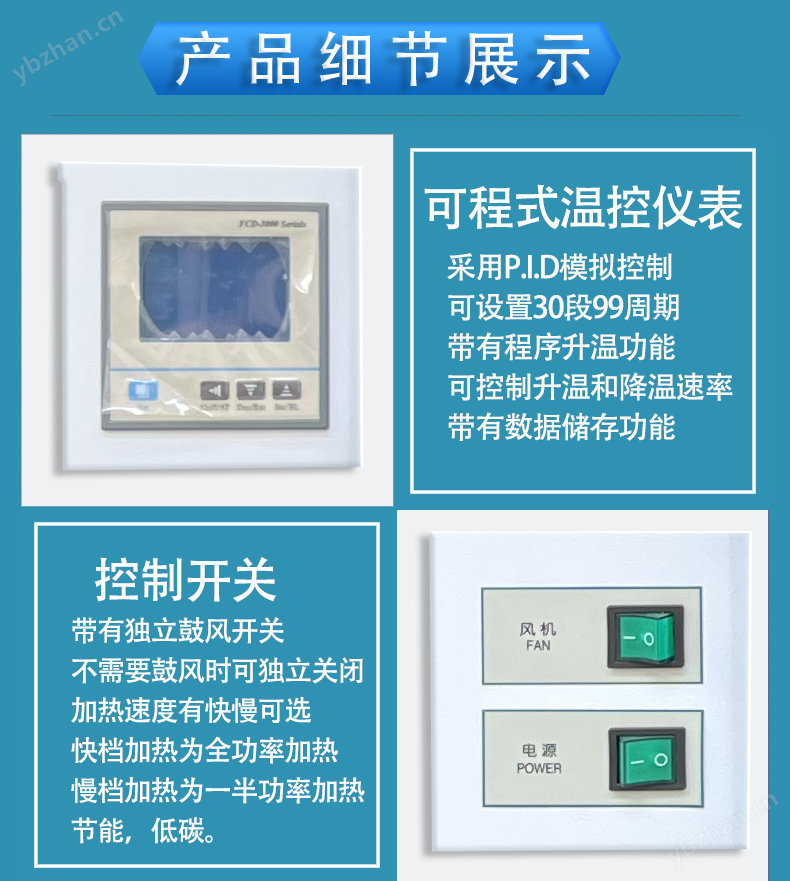

PID temperature control systemDynamically adjust the heating power through the proportional integral derivative algorithm to ensure that the temperature fluctuation range is controlled within ± 0.5 ℃, meeting the drying requirements of precision components.

Hot air circulation designThe top air outlet and bottom return air form a vertical circulating airflow, which is coordinated with the layout of the air duct inside the box to reduce temperature gradients and avoid local overheating.

Security protection mechanismIncluding automatic power-off due to overheating, pressure relief protection, and door lock linkage power-off functions to prevent equipment or sample damage caused by operational errors.

Question and Think:

Why is forced hot air circulation more suitable for drying electronic components than natural convection?

How to balance the drying temperature and material tolerance limit in semiconductor packaging process?

2、 Core advantages and performance characteristics

In response to the high sensitivity of electronic components to environmental conditions, the electric constant temperature blast drying oven exhibits the following advantages:

| feature | Traditional drying method | Electric constant temperature blast drying oven |

|---|---|---|

| temperature uniformity | Dependent on natural convection, prone to temperature differences | Forced circulation ensures temperature consistency inside the box |

| Drying efficiency | Long duration and high energy consumption | Programmable timing to shorten processing cycle |

| safety | Lack of multi-level protection mechanism | Multiple protections such as over temperature alarm and automatic pressure relief |

| adaptability | Fixed process, low flexibility | Support gradient heating and multi-stage program control |

In addition, the equipment adopts a mirror stainless steel inner liner and a rust proof coating shell, which is easy to clean and can resist the erosion of acidic and alkaline gases, suitable for handling materials such as electronic adhesives and solder pastes.

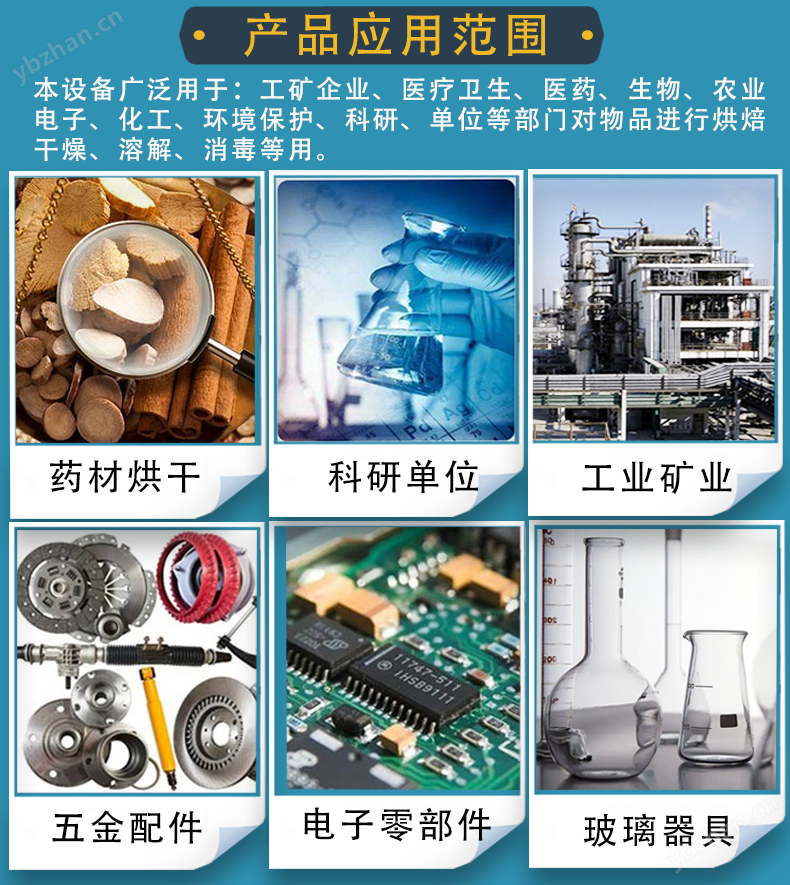

3、 Typical application scenario analysis

The drying requirement of electronic components runs through the entire production process, and the following are practical cases of several key links:

Pre drying and post-processing of circuit boards

problemBefore soldering, the surface moisture of the circuit board needs to be removed, otherwise high-temperature soldering may cause the phenomenon of "board explosion".

SolutionSet a low temperature range of 60-80 ℃ for initial drying, then raise it to 120 ℃ to complete final curing, and optimize process parameters through humidity monitoring throughout the process.

Curing of semiconductor packaging materials

demandEpoxy resin, silicone and other packaging materials need to undergo cross-linking reaction under constant temperature conditions to ensure bonding strength and insulation performance.

Key Operating PointsAdopting a segmented heating program (such as a gradient rise of 30 ℃/h) to avoid material cracking due to sudden heating.

Dehumidification of sensitive components before storage

challengeCeramic capacitors, crystal oscillators, and other components are sensitive to humidity and require strict control of moisture content for long-term storage.

coping strategySet up a low humidity environment (relative humidity<30%) and combine it with vacuum assisted drying technology to shorten the dehumidification time.

Question extension:

How to avoid deformation of the substrate due to high temperature during the drying process of flexible circuits (FPC)?

Do we need to upgrade the cleanliness requirements of the drying oven for nanoscale electronic materials?

4、 Usage precautions and maintenance suggestions

Load uniformitySample placement should avoid areas directly blown by the fan to prevent local overheating or uneven cooling.

periodic calibrationIt is recommended to verify the temperature sensor and temperature control module every quarter to ensure long-term operational accuracy.

Ventilation designIf dealing with volatile solvents, it is necessary to connect an external exhaust pipe and equip it with a filtering device to avoid gas accumulation and potential safety hazards.

5、 Technological adaptability in multiple scenarios

The electric constant temperature blast drying oven is not a "universal device", and its performance needs to be adjusted according to specific needs. For example:

Small batch R&D scenariosDesktop models can be selected to quickly reproduce experimental conditions through program memory function.

Large scale production lineIt is necessary to match vertical high-capacity models and integrate PLC control systems to achieve automated batch processing.

Special material processingFor thermosensitive materials (such as certain polymer films), a low-temperature slow drying strategy should be combined to avoid structural damage.

Case Comparison:

In the LED packaging process, a certain company once caused the fluorescent powder layer to peel off due to high drying temperature. Later, by reducing the heating rate and increasing humidity monitoring, the yield was improved by 12%.

Conclusion

Electronic component electric heating constant temperature blower drying ovenAs the infrastructure of electronic manufacturing, its technological iteration is directly related to product yield and process stability. By deeply understanding its working principle and applicable scenarios, engineers can design drying processes more efficiently, providing reliable guarantees for the production of high-precision electronic components.