-

E-mail

99495079@qq.com

-

Phone

13882197191 或者 18081927191

-

Address

No. 4-14, Building 3, No.1 Yinxing Road, Jinniu District, Chengdu City

Chengdu Litong Technology Co., Ltd

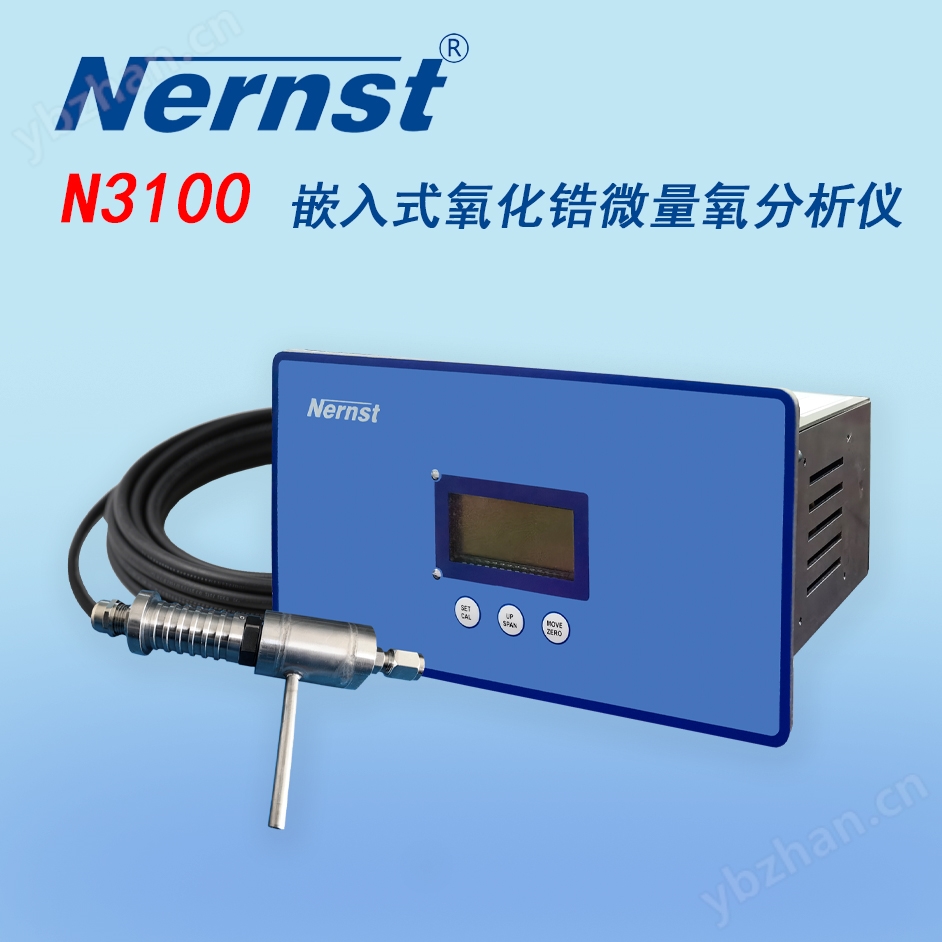

Embedded zirconia trace oxygen analyzer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Nernst N3100Embedded zirconia trace oxygen analyzerProduct Details

Overview

NernstEmbedded zirconia trace oxygen analyzerIt is the 7th generation trace oxygen analyzer designed and manufactured by Nernst. Widely used in vacuum welding furnaces, chip manufacturing in the electronics industry, reflow soldering, glove box oxygen measurement, 3D printing, biopharmaceutical industry, precision parts bright annealing furnaces, high-strength alloy tool coating processing equipment, as well as various process fields that require oxygen control on small equipment. The measured micro oxygen content can reach 10-30% to 100% oxygen content. The analyzer provides real-time data on the O2% (percentage) content of flue gas in the furnace or flue, as well as 12 other useful parameters. Trace oxygen analyzer is also suitable for various other fields that require high-precision measurement of oxygen content.

feature

Direct insertion fast response zirconia sensor

The Nernst zirconia sensor adopts sheet zirconia ceramic welding and fastening composite technology. The sensor has strong thermal shock resistance and generally does not require standard air calibration (can be calibrated with ambient air). The sensor has high oxygen measurement accuracy, fast reaction speed, no signal drift, and strong corrosion resistance during use. The actual response time is less than 100 milliseconds, and the sensor's response time to oxygen is 50 milliseconds.

Accurate sensor temperature control

The temperature of the sensor is crucial for reliable performance and fast response. The sensor comes with a heater component, which is precisely controlled by an analyzer to maintain the sensor at 720 ℃ at all times.

Large oxygen measurement range and high oxygen measurement accuracy

The measured micro oxygen content can reach 10-30% to 100% oxygen content.

maintenance-free

The analyzer does not require any regular maintenance, and the sensor does not need to be calibrated on a regular basis, only as needed.

compact design

The analyzer is very easy to install. Due to its embedded design and small size, it can be installed on the surface of the control panel and integrated into various device components.

output control

The analyzer has a 4-20mA current output and a computer communication interface RS232 or a network communication interface RS485.

display function

The analyzer adopts an easy to read high brightness LED display screen, which can display various functions and parameters, and has strong output and control functions for various parameters.

Oxygen display unit

Percentage content%, PPM mode, Scientific notation X-E% automatic conversion.

Alarm Settings

The analyzer has 3 universal alarm outputs, including 1 high oxygen alarm, 1 low oxygen alarm, and 1 programmable fault alarm.

Automatic or fixed range measurement

The analyzer can be configured to automatically change the measurement range based on the concentration of oxygen during the process.

easy to operate

The analyzer is set up at the factory. Users can directly enter the menu and change configuration parameters through the buttons on the analyzer panel.

Sensor specifications and parameters

Sensor Model |

N301 |

sensor type |

High precision zirconia sensor |

accuracy |

Measurement accuracy ± 0.5 ppm, repeatability accuracy ± 0.2 ppm |

response time |

<100 milliseconds |

heating time |

10 minutes to reach working temperature |

Sensors can withstand pressure |

Positive pressure: 500kpa, negative pressure: 1 Torr |

Sensor connection interface |

M18 × 1.5 thread |

Analyzer specifications and parameters

Analyzer model |

N3100 |

Scope of operation |

0-10ppm,0-100ppm,0-1000ppm,0-10000ppm,0-5%,0-10%,0-100%, 可调 |

display |

60 × 32mm LED LCD display |

power supply |

85V~240V AC 3A |

Temperature and humidity of the installation environment for the analyzer |

-25~50℃,5%~95% RH |

Analog current output |

Linear 4-20mA DC output (maximum load 600 Ω) |

relay output |

Three alarm relays, including high and low oxygen alarms, and fault alarms (programmable) |

通信端口 |

RS232 (optional percentage or PPM), RS485 |

Protection level |

IP65 |

warranty |

12 months from the date of shipment |

weight |

Analyzer 1.2kg/sensor with outer protective tube 170g |