The TK502/7D series controller adopts a bellows sensor, which can be used for neutral gases such as air, gas, and water vapor, as well as liquid media such as water, refrigerant, and oil. The setting value of the $r $n controller is adjustable. Adjustment range -0.1... 2.5MPa.

Top 500 private enterprises in China, Anhui Province enterprises, Anhui Province optical and cable industry base, Chinese wire and cable enterprises, large and professional temperature instrument production enterprises in China, and suppliers of complete sets of temperature, pressure, liquid level, flow, and material level. :138 5505 8800

|

D502/7DExplosion proof pressure controllerDetailed information: |

|

D502/7D、D502/7DK

pressure controller |

D502/7D

Explosion proof pressure controller |

|

|

|

Process of action of single pole double throw micro switch:

Terminal 1-3

Connect terminals 1-2 when the pressure rises and the switching value is reached

Disconnected when switching values due to increased pressure |

|

Process of action of single pole double throw micro switch:

Terminal 1-3

When the pressure rises and the switching value is reached, it is connected

Terminal 1-2

Disconnected when switching values due to increased pressure |

|

| The controller adopts a corrugated tube sensor, which can be used for neutral gases such as air, gas, and water vapor, as well as liquid media such as water, refrigerant, and oil. The setting value of the controller is adjustable. Adjustment range -0.1... 2.5MPa. |

|

1、 Technical performance is required

|

普通型 |

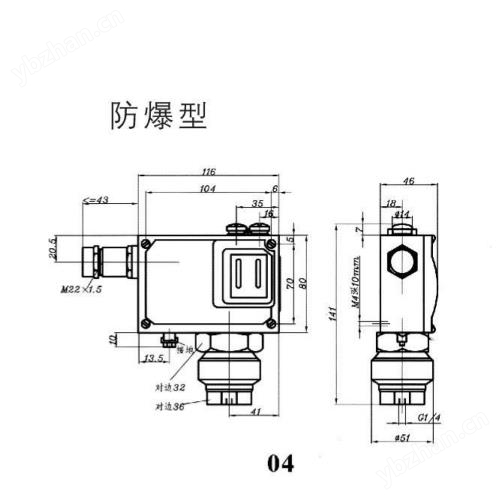

Explosion-proof type |

| Working viscosity |

<1×10-3m2/s |

<1×10-3m2/s |

| switching element |

micro switch |

micro switch |

| Explosion-proof rating |

—— |

ExdeⅡCT5 |

| Shell protection level |

IP65 (compliant with DIN40050, equivalent to IP65 in GB4208) |

IP54 (compliant with DIN40050, equivalent to IP54 in GB4208) |

| ambient temperature |

-5~40℃ |

-5~40℃ |

| medium temperature |

0~120℃ |

0~120℃ |

| Installation location |

|

Pressure interface vertically downward |

| Anti vibration performance |

D502/7D:40m/s2

D502/7DK:20m/s2

|

Max:20m/s2

|

| Repetitive component error |

≤1% |

≤1% |

| Contact capacity |

AC 220V 6A (resistive) |

DC 250V 0.25A (resistive) 60 Wmax

AC 250V 5A (resistive) 1250 VAmax |

|

| 2、 Product Features |

| Can be used for vacuum. |

3、 Specification and model

D502/7D switching difference is not adjustable

| Setting value adjustment range MPa |

Switching difference not greater than |

Maximum allowable pressure*

MPa |

Switching frequency

times |

Pressure sensor material |

Internal thread of interface |

Weight kg |

Outline dimension drawing number |

Order catalog number |

Set value range

lower limit

MPa |

Set value range

upper limit

MPa |

shell |

bellows |

普通型 |

Explosion-proof type |

普通型 |

Explosion-proof type |

-0.1……0

-0.1……0.1

-0.1……0.16

-0.1……0.25

|

0.006

0.007

0.008

0.009

|

0.007

0.008

0.009

0.012 |

1

1

1

1 |

20 |

brass |

stainless steel

00Cr17Ni14M02

(316L) |

G1/4'

G1/4'

G1/4'

G1/4' |

1.0

1.0

1.0

1.0 |

01

01

01

01

|

04

04

04

04

|

0810100

0810200

0810300

0810400 |

0850180

0850280

0850380

0850480 |

0……0.1

0……0.16

0.01……0.25

|

0.007

0.008

0.009 |

0.008

0.009

0.01 |

1

1

1

|

G1/4'

G1/4'

G1/4'

|

1.5

1.5

1.5

1.5

|

01

01

01

01

|

04

04

04

|

0811100

0811200

0811300

|

0851180

0851280

0851380 |

0.02……0.4

0.03……0.6

0.03……1 |

0.03

0.03

0.03 |

0.03

0.035

0.04 |

2

2

2

|

G1/4'

G1/4'

G1/4'

|

0.85

0.85

0.85

0.85

|

02

02

02 |

05

05

05 |

0811400

0811500

0811600 |

0851480

0851580

0851680 |

0.05……1.6

0.05……2.5 |

0.07

0.07 |

0.08

0.09 |

5

5 |

G1/4'

G1/4'

|

0.9

0.9 |

03

03 |

06

06 |

0811700

0811800 |

0851780

0851880 |

|

D502/7D switching difference adjustable

| Setting value adjustment range MPa |

Switching differential adjustment range |

Maximum allowable pressure*

MPa |

Switching frequency

times |

Pressure sensor material |

Internal thread of interface |

Weight kg |

Outline dimension drawing number |

Order catalog number |

Set value range

lower limit

MPa |

Set value range

upper limit

MPa |

shell |

bellows |

普通型 |

Explosion-proof type |

普通型 |

Explosion-proof type |

-0.1……0

-0.1……0.1

-0.1……0.16

-0.1……0.25

|

0.018…0.08

0.019…0.1

0.02…0.2

0.022…0.25 |

0.019…0.08

0.021…0.1

0.022…0.2

0.024…0.25 |

1

1

1

1 |

20 |

brass |

stainless steel

00Cr17Ni14M02

(316L) |

G1/4'

G1/4'

G1/4'

G1/4' |

1.05

1.05

1.05

1.05 |

01

01

01

01

|

04

04

04

04

|

0800100

0800200

0800300

0800400 |

0840180

0840280

0840380

0840480 |

0……0.1

0……0.16

0.01……0.25

|

0.015…0.08

0.018…0.1

0.02…0.2 |

0.016…0.08

0.02…0.1

0.024…0.2

|

1

1

1

|

G1/4'

G1/4'

G1/4'

|

1.05

1.05

1.05

1.05

|

01

01

01

01

|

04

04

04

|

0801100

0801200

0801300

|

0841180

0841280

0841380

|

0.02……0.4

0.03……0.6

0.03……1 |

0.08…0.25

0.08…0.5

0.09…0.8 |

0.08…0.25

0.09…0.5

0.1…0.8

|

2

2

2

|

G1/4'

G1/4'

G1/4'

|

0.9

0.9

0.9

|

02

02

02 |

05

05

05 |

0801400

0801500

0801600 |

0841480

0841580

0841680 |

0.05……1.6

0.05……2.5 |

0.17…1.2

0.18…2 |

0.19…1.2

0.2…2 |

5

5 |

G1/4'

G1/4'

|

0.95

0.95 |

03

03 |

06

06 |

0801700

0801800 |

0841780

0841880 |

|

D502/7DK switch difference is not adjustable (small switch difference, no explosion-proof type)

| Setting value adjustment range MPa |

Switching difference not greater than |

Maximum allowable pressure * MPa |

Switching frequency

times |

Pressure sensor material |

Internal thread of interface |

Weight kg |

Outline dimension drawing number |

Order catalog number |

Set value range

lower limit

MPa |

Set value range

upper limit

MPa |

shell |

bellows |

-0.1……0

-0.1……0.1

-0.1……0.16

-0.1……0.25

|

0.003

0.003

0.003

0.0045 |

0.0045

0.005

0.0065

0.01 |

1

1

1

1 |

20 |

brass |

stainless steel

00Cr17Ni14M02

(316L) |

G1/4'

G1/4'

G1/4'

G1/4' |

1.0

1.0

1.0

1.0 |

01

01

01

01

|

0810107

0810207

0810307

0810407 |

0……0.1

0……0.16

0.01……0.25

|

0.003

0.003

0.0045 |

0.0045

0.006

0.007

|

1

1

1

|

G1/4'

G1/4'

G1/4'

|

1.0

1.0

1.0

1.0

|

01

01

01

01

|

0811107

0811207

0811307

|

0.02……0.4

0.03……0.6

0.03……1 |

0.012

0.015

0.018

|

0.016

0.02

0.03 |

2

2

2

|

G1/4'

G1/4'

G1/4'

|

0.85

0.85

0.85

|

02

02

02 |

0811407

0811507

0801607 |

0.05……1.6

0.05……2.5 |

0.03

0.03 |

0.05

0.06 |

5

5 |

G1/4'

G1/4'

|

0.9

0.9 |

03

03 |

0811707

0811807 |

|

|

Our company's after-sales service commitment:

If users encounter any problems while using the products provided by our company, they can receive support and assistance. Users can primarily communicate with our company's customer service center. Once a user's request is received, professional engineers from the customer service department will solve or answer the questions raised by the user within the specified time. In addition, our company has 24-hour after-sales service to ensure a response within 24 hours after receiving user notifications. For those that require personnel to handle, the company will dispatch service personnel to the scene within a reasonable time to ensure that the equipment can resume normal operation as soon as possible.

Our company's service tenet:

The company adheres to the principle of "serving customers, being responsible for customers, and satisfying customers", conscientiously implements the requirements of ISO9001 quality system standards, and continuously improves the product and service quality of the enterprise.