-

Phone

15972987761

-

Address

Building 6, Optics Valley Headquarters, No. 35 Optics Valley Avenue, Wuhan

Product Categories

Wuhan Dongtai Borui Automation Equipment Co., Ltd

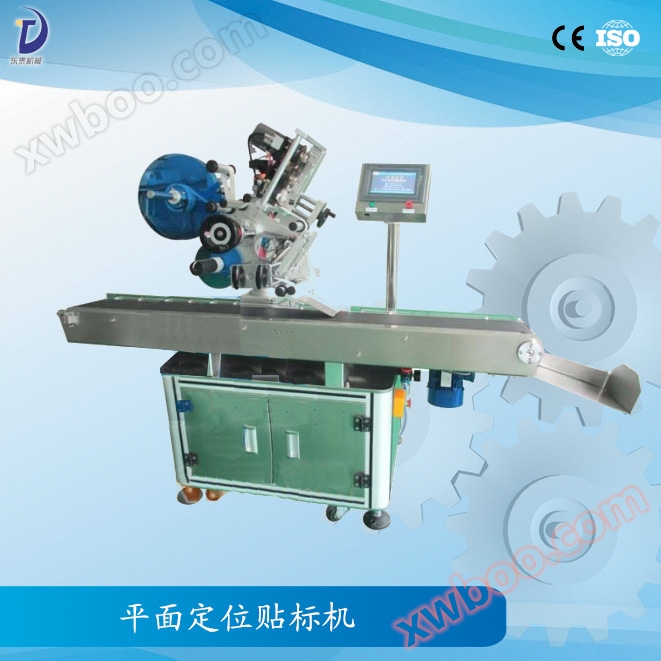

Flat positioning labeling machine

NegotiableUpdate on 12/10

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Product Name: Flat Positioning Labeling Machine Flat Positioning Labeling Machine Introduction: This flat positioning labeling machine is designed by Dongtai Borui Automation to achieve reasonable and beautiful labeling effects

Product Details

Product Name: Flat Positioning Labeling Machine

Introduction to Flat Positioning Labeling Machine:

This flat positioning labeling machine is designed by Dongtai Borui Automation to achieve reasonable and beautiful labeling effects. It gathers many advanced technology, microcomputer automatic control, and friendly interface touch screen. The labeling process is automated, with simple operation, fast production speed, unified labeling position, beautiful and neat appearance. It is mainly suitable for automatic labeling of various sizes of products in industries such as medicine, food, cosmetics, stationery, etc. It can work vertically or be matched with printers or inkjet printers to complete production line operations.Technical parameters:

Labeling speed: 0-25 meters/minute, adjustable freely

Labeling accuracy:+1mm

Applicable paper roll inner diameter: Dia.75mm

Outer diameter of large paper roll: Dia.370mm

Applicable voltage: 110V/220V, 50/60HZ

Standard label height: below 130mm

Large label height: 200mm

Mechanical dimensions: length * width * height 1400 * 700 * 1440mm

Mechanical weight: 65kg

Scope of application:

1. Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc;

2. Applicable products: products that require labels or films to be attached on flat or large curved surfaces;

3. Application industries: widely used in industries such as food, toys, daily chemicals, electronics, pharmaceuticals, hardware, plastics, etc;

4. Application examples: SD card labeling, mobile phone lens film, electronic accessory labeling, plastic box labeling, etc;

Equipment detail diagram:

Product advantages:

1. Micro design of mechanical structure, occupying less space, and convenient for equipment movement and placement in the assembly line;2. Adopting product oriented gap elimination mechanism and label anti deviation mechanism, the labeling positioning accuracy is as high as ± 1mm;

3. Good labeling stability, flat, wrinkle free, and bubble free labeling, which can meet the labeling requirements of most products on flat and large curved surfaces;

4. The clever design of the structured combination and label winding of the mechanical adjustment part makes it easy to fine tune the degree of freedom of the labeling position (which can be fixed after adjustment), making the conversion and label winding between different products simple and time-saving;

5. It has the functions of no labeling for items, automatic calibration and detection for items without labels;

6. The main materials of the equipment are stainless steel and high-grade aluminum alloy, with a sturdy and aesthetically pleasing overall structure;

7. Adopting a standard PLC+touch screen+servo motor+standard sensor electronic control system, with a high safety factor, the human-machine interaction interface is fully annotated in Chinese and has complete fault handling prompt and operation teaching functions; Easy to use and simple to maintain;

8. Complete equipment supporting information (including equipment structure, principle, operation, maintenance, repair, upgrade, etc.), providing sufficient guarantee for the normal operation of the equipment;

9. It has fault alarm function, production counting function, power saving function (when there is no labeling within the set time, the equipment automatically switches to power-saving standby mode), production number setting prompt function, parameter setting protection function (parameter setting is managed by permission);

10. Optional features:

① Hot coding/spray coding function

② Automatic feeding function (considering the product)

③ Automatic material receiving function (considering the product)

④ Add labeling device

⑤ Other functions (customized according to customer requirements)

Equipment front view:

The mechanical structure and functions of each part of the labeling machine are shown in the following diagram:

| Serial Number | Institution Name | Mechanical descriptions |

| 1 | Material sorting organization | Used to separate stacked products into individual pieces |

| 2 | main switch | The main power switch of the entire machine |

| 3 | transport mechanism | Transport the product to the labeling position, label it, and then transport it to the receiving mechanism |

| 4 | Material receiving institution | Undertake the products that have been labeled and transported over |

| 5 | Review institution | Press the label attached to the product tightly |

| 6 | Posting header | The core component of labeling, realizing the labeling function |

| 7 | Touch Screen | Human computer dialogue window for adjusting various parameters |

| 8 | electric box | Labeling machine electrical control center, equipped with various controllers and PLCs |

Partial view:

| Serial Number | Institution Name | Mechanical descriptions |

| 1 | Material tray | Used for packaging and labeling |

| 2 | brake | Used to brake the label, prevent it from loosening, and maintain the tension of the label tape |

| 3 | roller | Bypass the label to ensure its tension |

| 4 | Label compression device | Tighten the label to ensure its tension |

| 5 | Electric eye holder | Install the calibration eye and move the eye forward and backward |

| 6 | traction mechanism | traction mechanism |

| 7 | Peel off label board | Peel off label |

| 8 | Pressure marking mechanism | Used for compressing labels |

| 9 | Material receiving institution | Recycling label backing paper |

| 10 | lateral adjustment | Adjust the left and right positions of the entire sticker head |

| 11 | longitudinal adjustment | Used to lift and lower the sticker head as a whole |

Customer Case:

Similar Product Recommend