-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Food industry electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1、 Working principle and core design of equipment

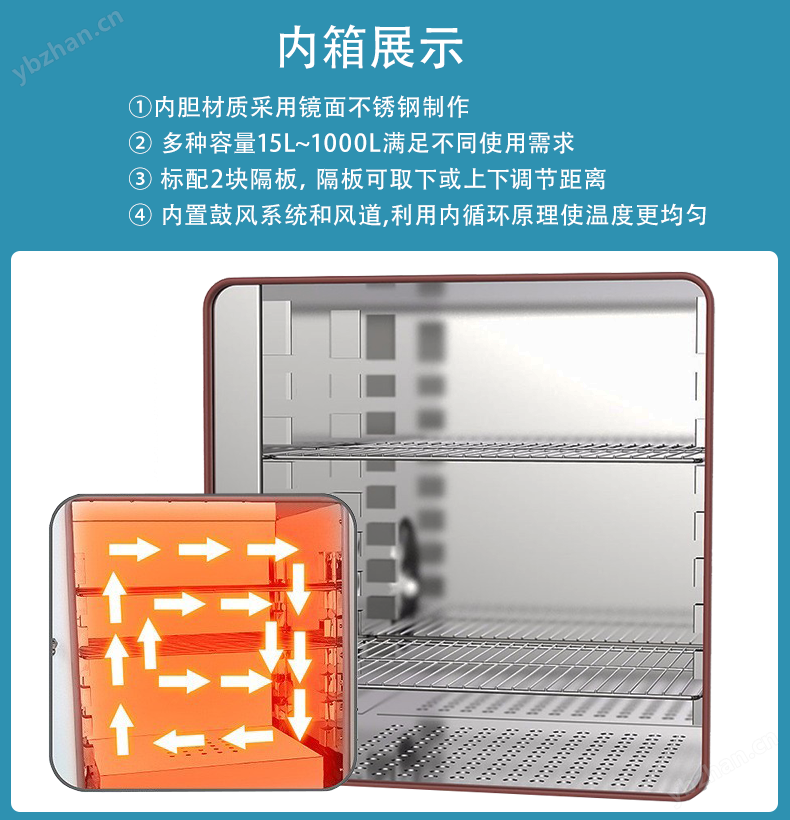

Food industry electric blast drying ovenBy generating heat through electric heating elements and using a blower system to force air circulation, the temperature inside the box is evenly distributed. Its core lies inHot air circulation systemandIntelligent temperature control technologyThe combination.

Hot air circulation systemBy driving the airflow with a fan, the heated air is evenly sent into the working chamber, forming a horizontal or vertical circulation flow. For example, in food drying, this design can accelerate water evaporation and carry away water vapor, avoiding local overheating and material deterioration.

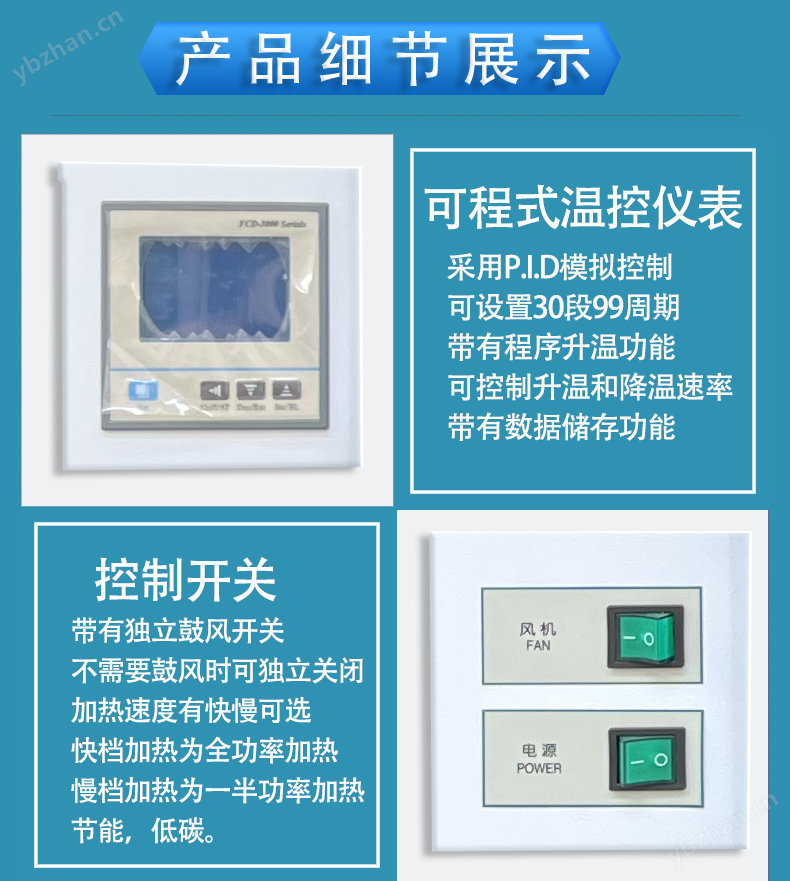

Temperature Control SystemPID (Proportional Integral Derivative) algorithm is used to adjust the heating power, ensuring that the temperature fluctuation range is controlled within ± 1 ℃. For heat sensitive foods such as nuts and dehydrated vegetables, precise temperature control can prevent nutrient loss.

questionWhy is air circulation crucial for the drying effect of food?

answer, solution, explanation, resolutionNatural convection can cause temperature gradients, while forced air blowing can break the static air layer, allowing heat to be evenly transferred to the surface of the material, while accelerating moisture diffusion and shortening the drying cycle.

2、 Key structural design and material selection

The food industry has high requirements for the hygiene and corrosion resistance of equipment, so structural design needs to balance functionality and safety.

| Design elements | Function and Characteristics |

|---|---|

| stainless steel inner pot | 304 stainless steel material is resistant to acid and alkali corrosion, meets food grade hygiene standards, and is easy to clean residues. |

| Double layered glass observation window | Real time monitoring of drying status, reducing temperature fluctuations caused by frequent door opening, suitable for food processing that requires observation of color changes. |

| Independent temperature limiting protection | When the temperature is abnormal, the power will be automatically cut off to prevent food safety risks caused by uncontrolled high temperatures. |

caseDuring the drying process of whey protein powder, the smooth surface of the inner liner can reduce protein adhesion and avoid cross contamination.

3、 Typical application scenario analysis

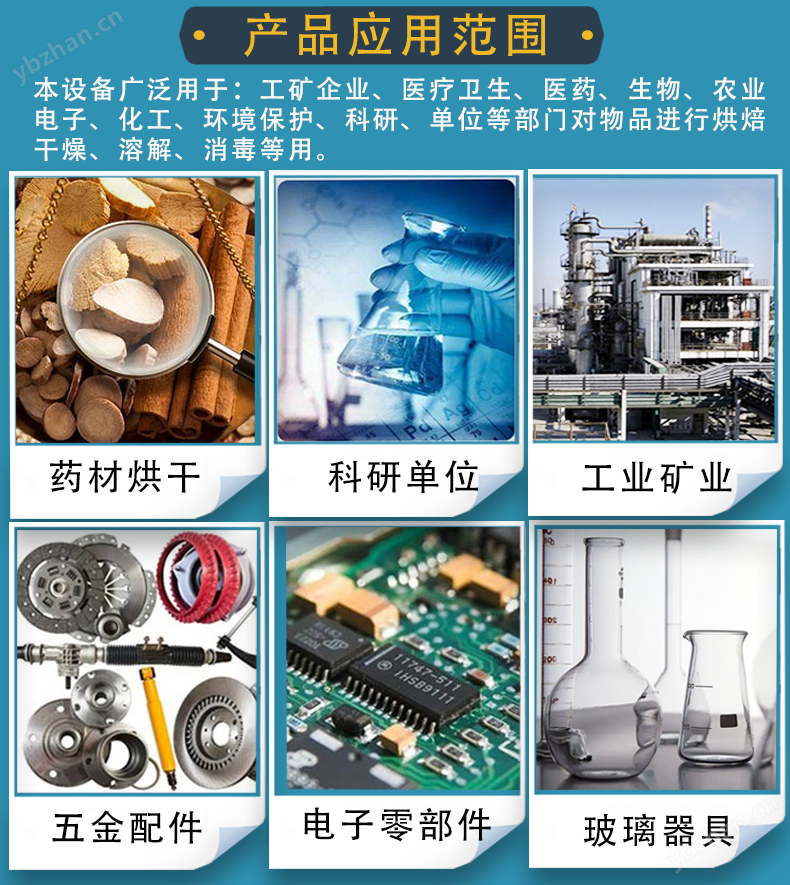

The application of electric blast drying oven in the food industry goes far beyond basic drying, and its versatility is reflected in the following scenarios:

Raw material dehydration treatment

sceneDrying of dried fruits, mushrooms, and seafood.

Technical PointsAdjust the wind speed and temperature according to the characteristics of the material. For example, low-temperature long-term drying (60-80 ℃) is suitable for high sugar dried fruits to prevent coking; High fiber vegetables can be processed using medium temperature and short-term techniques.

Sterilization and Disinfection

sceneSterilization treatment of baking ingredients (such as flour and starch).

Technical PointsThrough high-temperature dry heat sterilization at 120-140 ℃, microorganisms are killed while preserving the flavor of the raw materials. Attention should be paid to avoiding protein denaturation caused by excessive heating.

Baking process optimization

sceneExperimental baking in a small bakery.

Technical PointsSimulate the industrial oven environment using a drying oven, test the dough expansion effect through programmed temperature control (such as segmented heating), and optimize formula parameters.

questionHow to balance drying efficiency and food quality?

suggestionThe optimal temperature time combination should be determined through pre experiments, taking into account the moisture content of the material, thermal conductivity characteristics, and target product requirements. For example, some nuts can achieve ideal brittleness by drying at 90 ℃ for 2 hours, while excessively high temperatures can damage the oil structure.

4、 Operation precautions and maintenance suggestions

Safety Specifications

Dry volatile solvents (such as ethanol) or flammable materials are prohibited, and explosion-proof equipment must be separately installed.

first timeBefore use, check the smoothness of the exhaust port to prevent moisture from accumulating and affecting the drying efficiency.

routine maintenance

Regularly clean the filter screen and air duct to avoid dust accumulation and reduce heat exchange efficiency.

For highly viscous materials such as honey, it is recommended to wipe the inner liner immediately after use to prevent residue carbonization.

troubleshooting

Abnormal temperature fluctuationsIt may be caused by a decrease in fan speed or aging of heating pipes, and the motor and electric heating elements need to be checked.

Slow heating upIt is necessary to confirm whether the environmental ventilation is good and whether the distance between the back of the equipment and the wall meets the requirements (recommended to be ≥ 20cm).

5、 Industry standards and equipment selection considerations

The food industry has strict compliance requirements for drying equipment, and equipment selection should be based on process requirements and industry standards

Health and Safety Certification

The equipment must comply with standards such as "Stainless Steel for Food Contact Materials" (GB 4806.9) to ensure that the materials are non-toxic and harmless.

The European and American markets often require FDA and EHEDG certification, and export equipment needs to plan compliance paths in advance.

Process adaptability

Desktop drying ovens can be used for small-scale experimental scenarios, while production lines need to be matched with industrial grade high-capacity models.

For thermosensitive materials (such as probiotic powder), priority should be given to models with low-temperature and constant temperature functions.

Balancing energy efficiency and cost

The use of efficient electric heating tubes and insulation materials can reduce energy consumption, but it requires a balance between initial investment and long-term operating costs.

Some enterprises further improve energy utilization efficiency through waste heat recovery systems.

Conclusion

Food industry electric blast drying ovenAs a fundamental equipment in food processing, its performance directly affects product quality and production efficiency. By rational design, standardized operation, and continuous optimization, reliable support can be provided for process innovation while ensuring food safety.