-

E-mail

sunny@chinayxjx.com

-

Phone

136-6249-5431

-

Address

No. 1315-1318, Building 2, Agile Science and Technology Innovation Center, Beitai Road, Taihe Town, Baiyun District, Guangzhou City

- Stainless steel emulsifier

- Cosmetics emulsifier

- Liquid washing production line

- Lotion emulsifying machine

- Stainless steel heating mixing tank

- Homogenizer emulsifier homogenizer

- aerosol filling machine

- Dispersing emulsifier

- Softened PVC water treatment

- Salad dressing emulsifier

- Stainless steel water treatment with mixed bed

- GZJ-Y fully automatic paste filling machine

- Liquid Filling Machine

- Semi-automatic filling machine

- Small filling machine

- Cream production line

- Softened stainless steel water treatment

Guangzhou Yuxiang Light Industry Machinery Equipment Co., Ltd

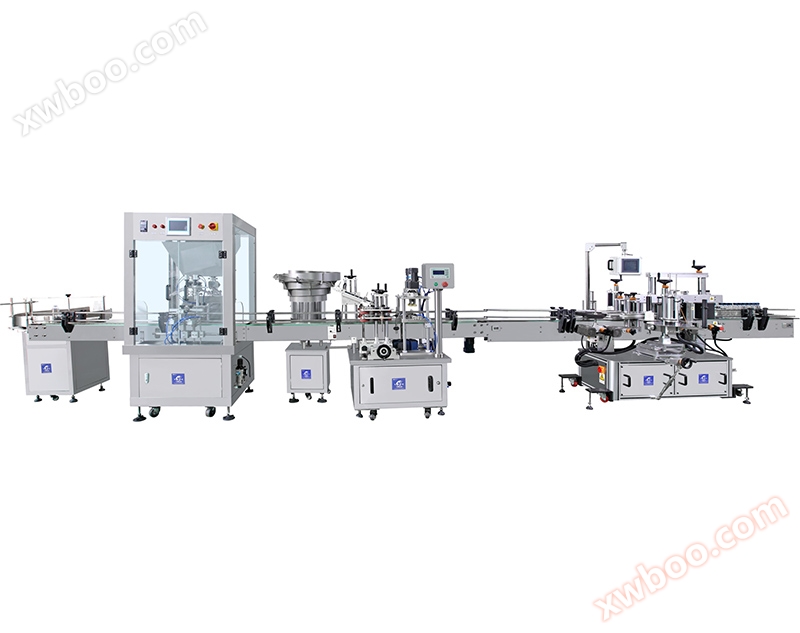

GZJ-Y fully automatic paste filling machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Product Features:

This model is suitable for the cosmetics, beverage, and pharmaceutical industries;

Adopting programmable logic controller (PLC) human-machine interface (HMI) technology and Korean imported photoelectric tracking switch, it can accurately identify the positioning status of filling bottles,

Realize bottle filling, no bottle filling with few bottles, and also have counting function.

The fully automatic filling production line adopts well-known brands of electrical and pneumatic components, with low failure rate, stable and reliable performance, and long service life;

|

Professional design team Professional design team

Yuxiang's professional design team, for youTailored to fit |

|

Efficient service team Efficient service team

Yuxiang's efficient service team,7 * 24 hours24/7 seamless operation |

|

Advanced production equipment Advanced production equipment

Yuxiang's advanced production equipment, excellent factory management, and wealth |

|

Equipment planning and design

According to the customer's production process, factory structure, production capacity, etc., our senior engineers will carry out equipment planning and design

Produce equipment drawings

According to the planning and design, create complete equipment drawings (CAD/3D) and pipeline layouts, which will be confirmed by the purchaser

Verify material and configuration

After placing the order, we will provide detailed production drawings and conduct a record review of the production equipment. During production, we will invite customers to participate in production supervision, verify materials and configurations

Conduct comprehensive acceptance

After production is completed, arrange quality inspection for comprehensive acceptance, and have detailed acceptance data for reference (including image data);

Debugging, installation, and training

After the equipment enters the buyer's factory, we will dispatch professional engineers to conduct on-site debugging, installation, and training

National Consultation Hotline:020-3667-0808

Manager Sun: 136-6249-5431

QQ:2850788655

E-mail: sunny@chinayxjx.com

Address: Agile Science and Technology Innovation Center, Beitai Road, Taihe Town, Baiyun District, Guangzhou City

Building 2, No. 1315-1318