-

E-mail

guanshikeji@guanshikeji.com

-

Phone

19170336680

-

Address

3-4/F, Building 31, No. 5 Chaoyang 2nd Road, Chaoyang Industrial Park, Xinzhou District, Shangrao City, Jiangxi Province

Jiangxi Guanshi Technology Co., Ltd

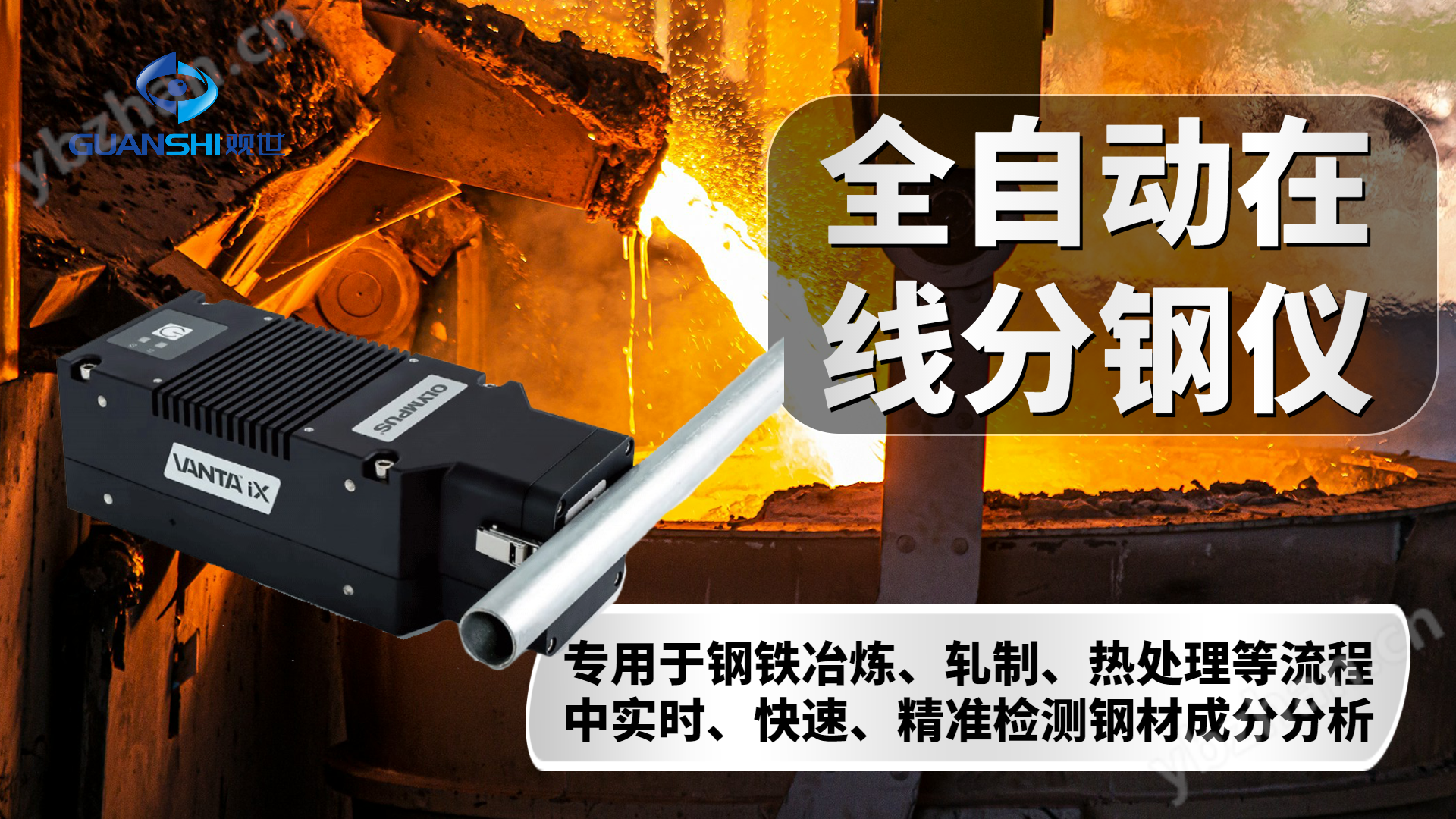

Industrial automation online robot steel analyzer equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Industrial automation online robot steel analyzer equipment

Accurate operation based on X-ray fluorescence analysis technology. The principle is to use different elements to emit specific wavelengths of X-ray fluorescence under X-ray irradiation. Qualitative analysis can be achieved by detecting the wavelength, and quantitative analysis can be completed by detecting the fluorescence value. It can operate continuously 24/7.

Industrial automation online robot steel analyzer equipment

In terms of industry applications, it covers multiple fields. In the field of metal alloy materials, it can quickly sort metals, automatically analyze metal grades, issue mixed material alarms, and analyze coating thickness and load capacity; In the field of ceramic materials, it is capable of conducting composition analysis on ceramics, cement, glass, and clay; In the field of environment, it can analyze the components of soil, sewage, solid waste, etc; In the field of cultural and archaeological research, it is suitable for component analysis of metal objects, clay objects, murals, and gemstones.

Guanshi Industrial Automation Online XRF Steel Divider Robot Steel Divider EquipmentProduct features are significant: online integration in real-time detection on the production line, automated operation without manual intervention, short and efficient detection time, 7X24 uninterrupted work, automatic data upload, accurate results, non-destructive to samples, no need to prepare samples, easy operation, and no need to contact chemical substances, high safety.

Accurate operation based on X-ray fluorescence analysis technology. The principle is to use different elements to emit specific wavelengths of X-ray fluorescence under X-ray irradiation. Qualitative analysis can be achieved by detecting the wavelength, and quantitative analysis can be completed by detecting the fluorescence value. It can operate continuously 24/7. Accurate operation based on X-ray fluorescence analysis technology. The principle is to use different elements to emit specific wavelengths of X-ray fluorescence under X-ray irradiation. Qualitative analysis can be achieved by detecting the wavelength, and quantitative analysis can be completed by detecting the fluorescence value. It can operate continuously 24/7.