-

E-mail

948029948@qq.com

-

Phone

19302919151

-

Address

Zhongxing Deep Blue Technology Industrial Park, Fengdong New City, Xixian New Area, Xi'an City

Xi'an Nuoke Instrument Co., Ltd

Infrared gas analyzer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

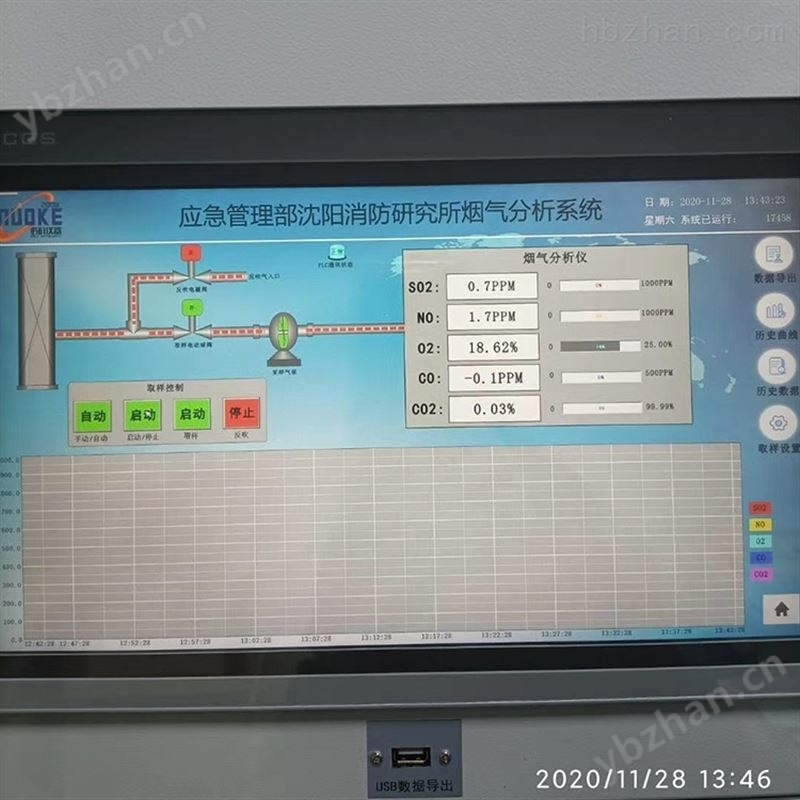

The NK-500 series infrared flue gas analyzer is widely used for measuring harmful gases and oxygen content in flue gas. The electrochemical gas sensor is the core of the flue gas analyzer for detecting gases. Scientific and reasonable use and maintenance can effectively extend the life of the electrochemical sensor.Infrared gas analyzerProper use, maintenance, and calibration are particularly important to ensure the accuracy of the measurement results, in order to guarantee the measurement accuracy of the flue gas analyzer.

The NK-500 series infrared smoke analyzer is an instrument for detecting harmful gases such as sulfur dioxide, nitric oxide, nitrogen dioxide, carbon monoxide emissions, and oxygen content. Used for environmental monitoring of pollution emissions from fuel and gas boilers, flue gas, and near pollution sources. Gas sensors are the core of flue gas analyzers for detecting gases, and commonly used gas sensors are electrochemical gas sensors. Electrochemical gas sensors have stable performance, long lifespan, low power consumption, fast response to gases, and are not affected by humidity. The resolution can generally reach 0.1 μ mol/mol (varying with different sensors).Infrared gas analyzerIts temperature adaptability is also relatively wide (sometimes it can work between -40 ℃ and 50 ℃). However, it is also greatly affected by temperature changes in readings. So many instruments have software and hardware temperature compensation processing. At the same time, electrochemical gas sensors have the advantages of small size, simple operation, easy portability, can be used for on-site monitoring, and low cost. Therefore, electrochemical gas sensors play an important role in various gas detection equipment, including flue gas analyzers.

Execution standard for infrared smoke comprehensive analyzer:

JJG968-2002 Smoke Analyzer

HJ/T397-2007 Technical Specification for Fixed Source Waste Gas Monitoring

HJ629-2011 "Determination of Sulfur Dioxide in Fixed Source Waste Gas by Non Dispersive Infrared Absorption Method"

HJ692-2014 "Determination of Nitrogen Oxides in Fixed Source Waste Gas by Non Dispersive Infrared Absorption Method"

HJ870-2017 "Determination of CO2 in Fixed Source Waste Gas by Non Dispersive Infrared Absorption Method"

HJ/T44-1999 "Determination of Carbon Monoxide in Exhaust from Fixed Pollution Sources - Non dispersive Infrared Absorption Method"

GB/T16157-1996 "Determination of particulate matter and sampling methods for gaseous pollutants in exhaust from stationary sources"

Characteristics of Infrared Smoke Comprehensive Analyzer:

1. Adopting imported long path multi-component infrared detection sensor

2. Innovative anti-interference algorithm, simultaneously measuring various smoke components such as SO2, NOx, CO2, CO, H2S, O2, etc

3. For measurement of high humidity, high dust and other working conditions, a pre-treatment device can be optionally selected

4. Sampling tube is resistant to high temperature, corrosion, adsorption, and lightweight

5. The smoke temperature line, communication line, power line, and gas path connection pipe are all in one, and the gas path connection adopts a quick connector

6. Optional networking module and printer

Main parameters of infrared smoke comprehensive analyzer:

1. Smoke temperature: -50 ℃~500 ℃

2. Smoke sampling flow rate 1.0L/min

3. Smoke concentration:

(a)O2:0~30%

(b)SO2:0~2860mg/m3

(c)NO:0~2000mg/m3

(d)CO2:0~20%

(e)NO2:0~200mg/m3

(f)CO:0~5000mg/m3

(g)H2S:0~300mg/m3

Note: The range can be customized