-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Intelligent PID temperature control electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

The accuracy and stability of temperature control directly affect experimental results or product quality in laboratories, industrial production, and scientific research fields.Intelligent PID temperature control electric blast drying ovenAs a common device, one of its core upgrade directions is to introduceIntelligent PID temperature control systemThis article will focus on this technology, exploring its working principle, application scenarios, and practical value.

1、 How can PID temperature control technology improve the performance of drying ovens?

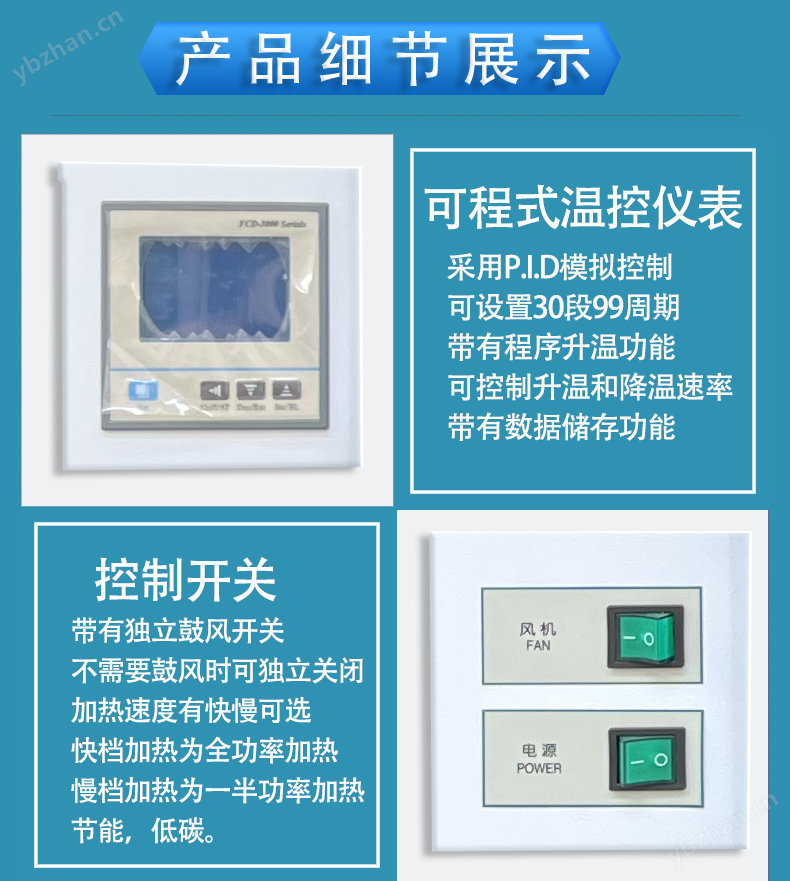

Traditional drying ovens often use simple switch type temperature control (such as relay control), which has problems such as large temperature fluctuations and delayed response. ButPID (Proportional Integral Derivative) Control AlgorithmBy dynamically adjusting the heating power, more precise temperature management can be achieved.

Analysis of PID Control Logic

Proportion (P)Adjust the heating intensity proportionally based on the deviation between the current temperature and the target value.

Integral (I)Eliminate long-term accumulated errors and avoid temperature deviation.

Differential (D)Predict the trend of temperature changes and suppress overshoot or undershoot in advance.

-

Comparison of actual effects

Control method Temperature fluctuation range response speed stability Traditional switch control ±3~5℃ slower average PID control ±0.5~1℃ quick significantly improve

2、 Why choose an intelligent PID temperature controlled drying oven?

Adapt to complex process requirements

In materials science, processes such as polymer curing and ceramic sintering require strict adherence to specific gradients in temperature curves. PID temperature control system supportMulti segment program settings(such as heating rate and constant temperature time) to meet the flexibility requirements of the process.Safety and reliability

Overtemperature protection mechanismWhen the temperature is abnormal, the independent temperature limiting system can automatically cut off the heating power supply to prevent equipment damage or sample failure.

Data recording functionSome models support temperature curve storage for easy traceability of experimental conditions (such as key data in drug stability testing).

energy efficiency optimization

By dynamically adjusting the heating power, energy waste can be reduced. For example, reducing the heating output during the constant temperature stage and maintaining only a small compensation power can maintain temperature stability.

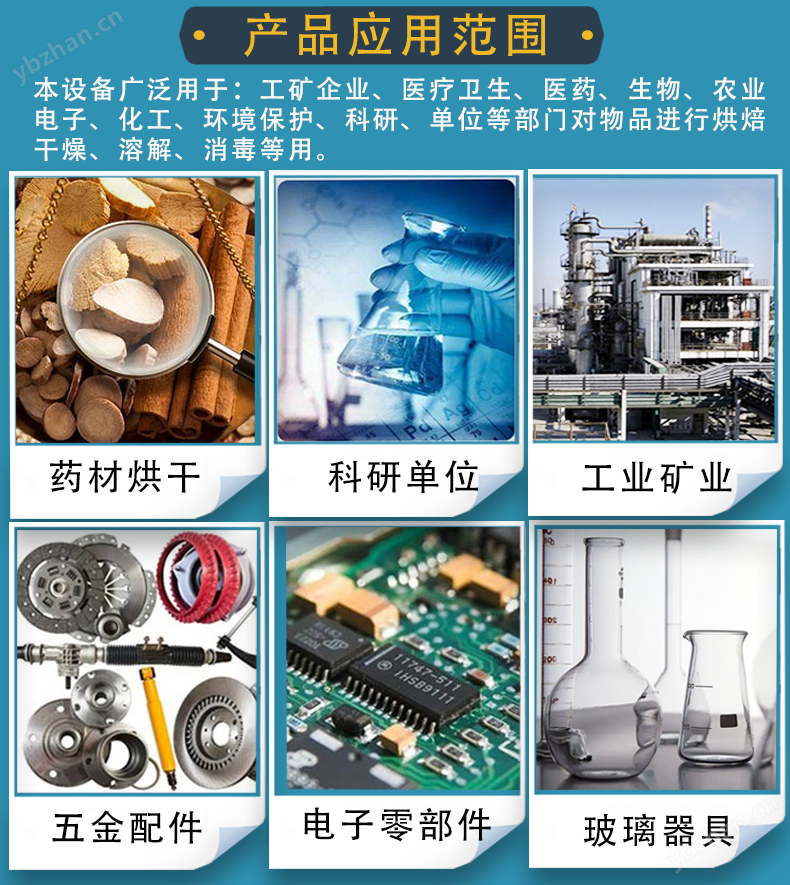

3、 Typical application scenario analysis

Laboratory sample processing

Application scenariosDrying of biological samples, dehydration of chemical reagents, and microbial sterilization.

Technical RequirementsHigh precision temperature control (± 0.5 ℃), low vibration environment, and fast recovery capability.

caseIn a plant specimen drying experiment at a certain university, the moisture content error was controlled within 3% through PID temperature control, which was significantly better than traditional equipment.

Material processing in industrial production

Application scenariosBaking of electronic components, drying of food, and curing of coatings.

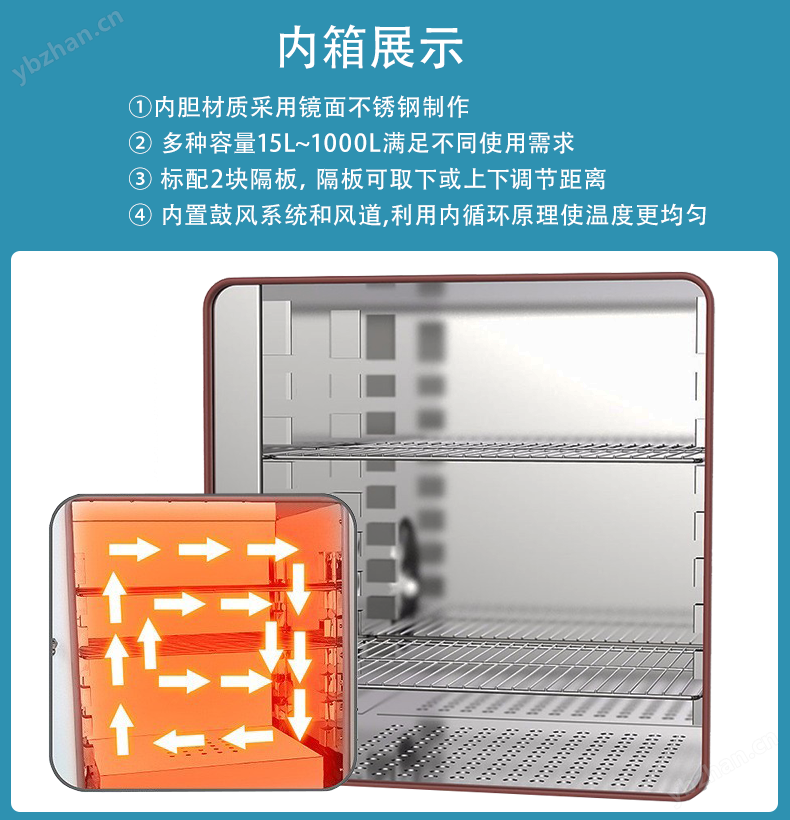

Technical RequirementsLarge capacity design, corrosion-resistant inner liner (such as SUS304 stainless steel), high temperature sealing resistance.

caseA semiconductor company used a PID temperature controlled drying oven for pre drying photoresist, reducing the batch defect rate by 15%.

Agriculture and Food Industry

Application scenariosDrying of grains, drying of medicinal herbs, and dehydration of fruits and vegetables.

Technical RequirementsAnti caking mixing system, anti debris filtration, multi-stage humidity management.

caseA certain traditional Chinese medicine processing factory has improved the retention rate of active ingredients by 8% by optimizing the drying curve.

4、 Key issues and suggestions in use

How to choose the appropriate temperature range?

It needs to be determined based on the characteristics of the material. For example:Low temperature drying(50-120 ℃): Suitable for thermosensitive substances (such as food and biological tissues).

Medium high temperature treatment(150-300 ℃): Used for sintering metal oxides or sterilizing glassware.

Precautions for equipment maintenance

Regularly clean the dust on the fan blades and heating wires to avoid local overheating.

Check the aging condition of the sealing strip to prevent heat leakage and increase in energy consumption.

Warning of operational errors

Frequent opening of doorsIt will cause a sudden drop in temperature and prolong the recovery time. It is recommended to take and store the samples in the later stage of drying.

Overloaded placementSample accumulation affects hot air circulation and may cause local temperature unevenness.

Conclusion

Intelligent PID temperature control electric blast drying ovenBy optimizing algorithms and upgrading hardware, the pain points of traditional devices in terms of accuracy, efficiency, and safety have been solved. Its application has expanded from a single drying function to a core tool for multi domain process control. For users, understanding its technical principles and matching application scenarios reasonably is the key to maximizing device performance.