-

E-mail

1170569713@qq.com

-

Phone

13401821290

-

Address

No. 18, East Gong'er Road, Jinhu County Industrial Park, Huai'an City, Jiangsu Province

Huai'an Qingchuan Instrument Co., Ltd

Intelligent Visual Layering Instrument (Liquid Image Layering Instrument)

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1Intelligent Visual Layering Instrument (Liquid Image Layering Instrument)Product Overview

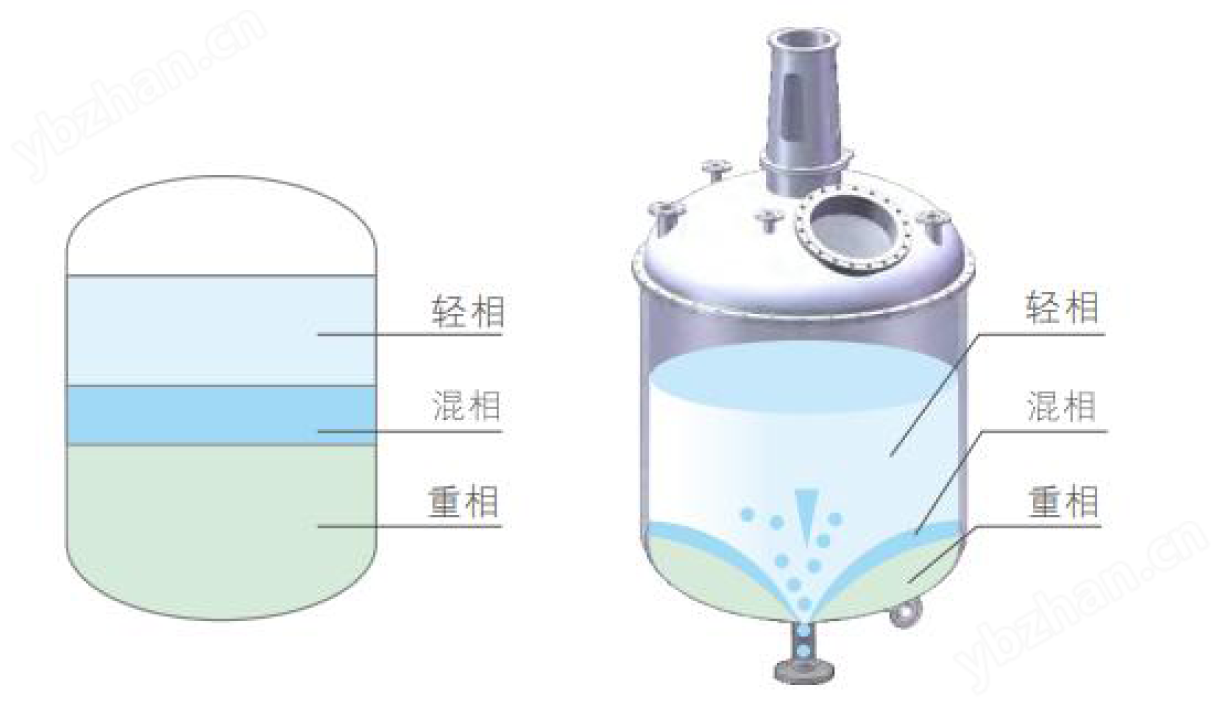

The intelligent visual layering system is a comprehensive system based on visual acquisition, detection, analysis, and control. Widely used in industries such as chemical, pharmaceutical, and food. This system is mainly a software system that utilizes advanced computer vision recognition technology and image processing algorithms to identify and analyze liquids in images or videos. This system can automatically detect and recognize liquids of different colors or depths of field, and extract their relevant feature information, providing accurate visual data processing solutions for industrial automation layering processes.

IIIntelligent Visual Layering Instrument (Liquid Image Layering Instrument)Measurement principle:

The principle of product measurement is mainly based on computer vision technology and image processing algorithms. Firstly, the system captures images or videos of the target liquid through visual acquisition devices. Then, the collected images or videos are preprocessed through detection modules, such as noise removal, establishment of multidimensional models, etc., for subsequent image analysis and processing. The system will utilize advanced computer vision recognition technology to identify liquids in preprocessed images or videos. This process is carried out to accurately identify the boundaries and material properties of the liquid. The system will analyze the identified liquid, including color analysis, depth of field analysis, etc. This step mainly uses image processing algorithms such as color histograms, gray level co-occurrence matrices, etc. to extract characteristic information such as color and depth of liquids. The system will integrate and process the extracted liquid characteristic information, and output the final measurement results.

3、 Product Features

Adopting optical detection, millisecond response, non-contact with materials, safe and reliable, suitable for layered process detection.

Clear layering of two-phase or multi-phase interfaces allows for easy operation without the need for on-site debugging.

It can effectively detect colorless and transparent liquid phases, multi-layer liquid phases, suspended solids, and mixed liquid phases.

The system comes with upper computer software and supports remote debugging. When multiple consecutive layers are required, the process flow (including feeding, etc.) can be configured by oneself to achieve full process automation.

By using proprietary PID algorithm, the vortex problem is effectively solved, greatly reducing process time and improving layering efficiency.

Equipped with self diagnosis and alarm functions, it can quickly determine instrument faults.

Equipped with insulation function, effectively avoiding problems such as material crystallization, precipitation, and solidification.

Equipped with a built-in cleaning system to ensure that the detection surface is not adhered, keeping the equipment in the best detection state at all times.

Explosion proof ExdbIICT6 Gb design provides effective protection for safety production.

4、 Product parameters

Product Dimension Drawing

5、 Product Selection Table

6、 Product Installation Diagram

7、 Product application areas

Extraction processes such as effective ingredient extraction, antibiotic extraction, and protein purification in the fields of pharmaceuticals and biotechnology.

Layering and control of fine chemical pickling process.

The chemical and petroleum industries purify finished products through layered processes such as metal extraction, oil refining, and organic synthesis.

Visual inspection and control of the interior of process pipelines.

8、 Advantages over peers

1. The layered feeding process will form a certain degree of vortex at the lower end of the reaction kettle. When the materials have some mixed phases, suspended solids, slight emulsification, bubbles or impurities may form due to similar densities. If the interference algorithm is not processed well enough, problems such as program confusion and erroneous layering may occur; Our product, through hardware and PID algorithm, shortens the process time and avoids the problem of ineffective layering caused by vortex mixing.

2. When encountering materials with darker colors, other mirrors may encounter interface recognition issues due to product structure reasons. Our product can effectively solve such problems through clever design and AI algorithms.

3. Currently, most mirror quotations do not include software, upper computer, and acquisition module. Our quotation includes the entire system.

9、 Comparison Table of Advantages and Disadvantages of Common Layered Devices