-

E-mail

2628879629@qq.com

-

Phone

18066558480

-

Address

Standard Factory Building on Chuangye Avenue, New Industrial Park, High tech Zone, Xi'an City

Product Categories

Xi'an Xiangyuan Technology Co., Ltd

Intelligent magnetostrictive liquid level gauge brand

NegotiableUpdate on 12/19

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Intelligent magnetostrictive level gauge is a high-precision magnetic level gauge sensor used for continuous measurement of liquid level and interface, and providing on-site display and analog signal output. Compared to traditional reed tube sensors, the sensing resolution of magnetostrictive level gauges has increased by more than 10 times.

Product Details

Intelligent magnetostrictive level gauge is a high-precision magnetic level gauge sensor used for continuous measurement of liquid level and interface, and providing on-site display and analog signal output. Compared to traditional reed tube sensors, the sensing resolution of magnetostrictive level gauges has increased by more than 10 times.

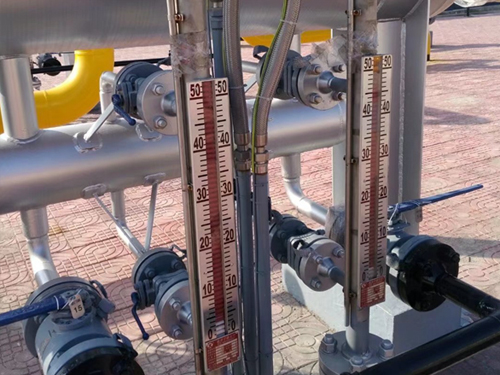

Its basic structure mainly consists of three parts: detection rod, circuit sensing element, and float. During the measurement process, the circuit sensing element generates a current pulse, which is transmitted downwards along the probe rod and generates a circular magnetic field. The float outside the detection rod will move up and down with the change of liquid level, and there is a set of magnetic steel inside the float, so the float itself will also generate a magnetic field. When the electromagnetic field generated by the circuit sensing element meets the magnetic field of the float, a "twisted" pulse is generated. The time difference between this "twisted" pulse and the current pulse can be converted into a pulse signal, which can then be used to calculate the actual position of the float and measure the liquid level.

Intelligent magnetostrictive liquid level gauges have the characteristics of high precision, strong environmental adaptability, and easy installation. Therefore, they are widely used in the industrial measurement and control of liquid levels in various liquid tanks such as petroleum, chemical, industrial processes, biochemistry, medicine, food and beverage, tank area management, and underground inventory of gas stations, as well as in the fields of dam water level, reservoir water level monitoring, and sewage treatment.

1、 Application scenarios

2、 Technical parameters

| Measurement requirements | liquid level | |

| Measure the guide rod | rigidity | flexible |

| Guide rod material | 304SS/316SS | 304SS/Plastic Material |

| Effective measurement range | 0.3-4.0 meters | 2-10 meters |

| Maximum process pressure | 2.5MPa (higher with magnetic flap level gauge) | 0.6MPa |

| Process medium temperature | -30-100 ℃ (up to 300 ℃ when combined with a magnetic flip plate) | -10~80℃ |

| resolution | 5mm or 1mm | |

| power supply | ±24VDC±30% | |

| output | 2-wire 4-20mADC/2-wire 4-20mADC+HART | |

| display | LCD screen display (mm, m, inch, foot,%, ℃ and debugging parameters) | |

| ambient temperature | -25~75 ℃ (including LCD display 0~70 ℃) | |

| ambient humidity | 0~95% | |

| float ball | Φ45,Φ52,Φ75 | |

| fault current | Can be set to 3.8 or 22mA | |

| damping | 1-2 seconds optional | |

| explosion-proof | optional | |

| process connection | Flanges, threads or according to user requirements | |

The design voltage of the liquid level gauge can operate between 12~36VDC. The larger circuit impedance (including power supply resistance) depends on the magnitude of the supply voltage, ranging from 0 to 1200 Ω. The minimum impedance of the HART communication terminal is 250 Ω.

3、 Complete set and installation of liquid level measurement and control system

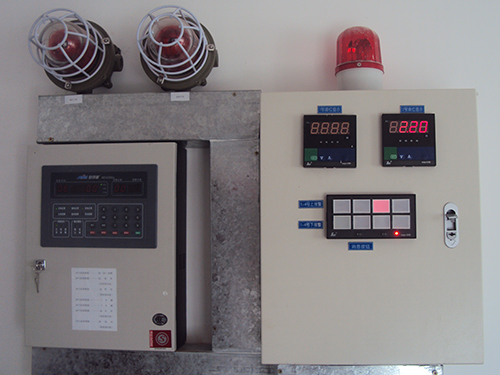

The company provides users with a liquid level control or monitoring system based on the UHFM series magnetostrictive liquid level gauge at their request.

Our company has extensive experience in liquid level measurement display and control systems. We can provide users with small complete sets of remote secondary instrument displays, alarm boxes, interlock pumps, and solenoid valve control boxes, and install and debug them according to requirements.

Similar Product Recommend