-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Laboratory small desktop electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Drying of samples is a common and critical step in daily laboratory work.Laboratory small desktop electric blast drying ovenAs a basic device, how to achieve efficient and uniform heating process? In which scenarios does it play an irreplaceable role? This article will explore its working principle, structural characteristics, and application fields.

Working principle and heating method

A small desktop electric blast drying oven generates heat through electric heating elements and, in combination with a fan, drives air circulation to evenly distribute the temperature inside the oven. Its core lies in utilizing the principle of convective heating to avoid local overheating or temperature fluctuations. This design can meet the experimental requirements for high temperature stability.

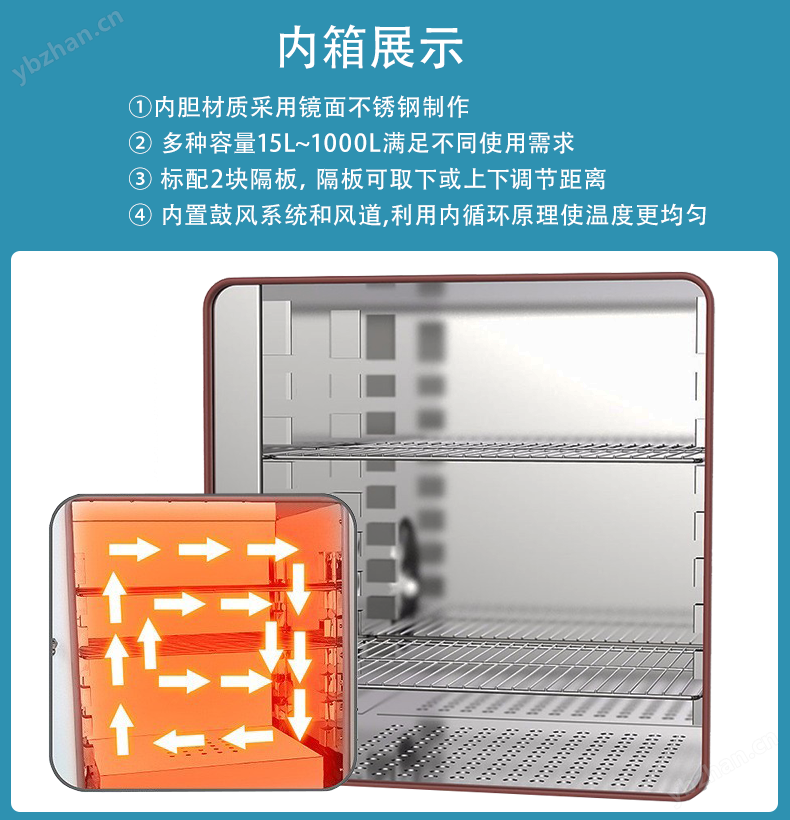

Why is the air circulation system crucial for the drying effect?

During the drying process, stagnant air can easily lead to heat accumulation, while the air circulation system uses forced convection to make the hot air flow evenly, thereby reducing temperature differences. This not only improves drying efficiency, but also ensures consistency in sample processing.

Structural composition and functional characteristics

This type of drying oven usually consists of a box body, heating module, air circulation system, temperature controller, and safety protection device. The following table lists its main components and functions:

| Component Name | Functional Description |

|---|---|

| box | Using insulation materials to reduce heat loss and ensure stable internal temperature. |

| heating module | Provide heat through electric heating wire or tubular heater, supporting adjustable temperature range. |

| Wind circulation system | Using a fan to drive air flow and achieve uniform temperature distribution inside the box. |

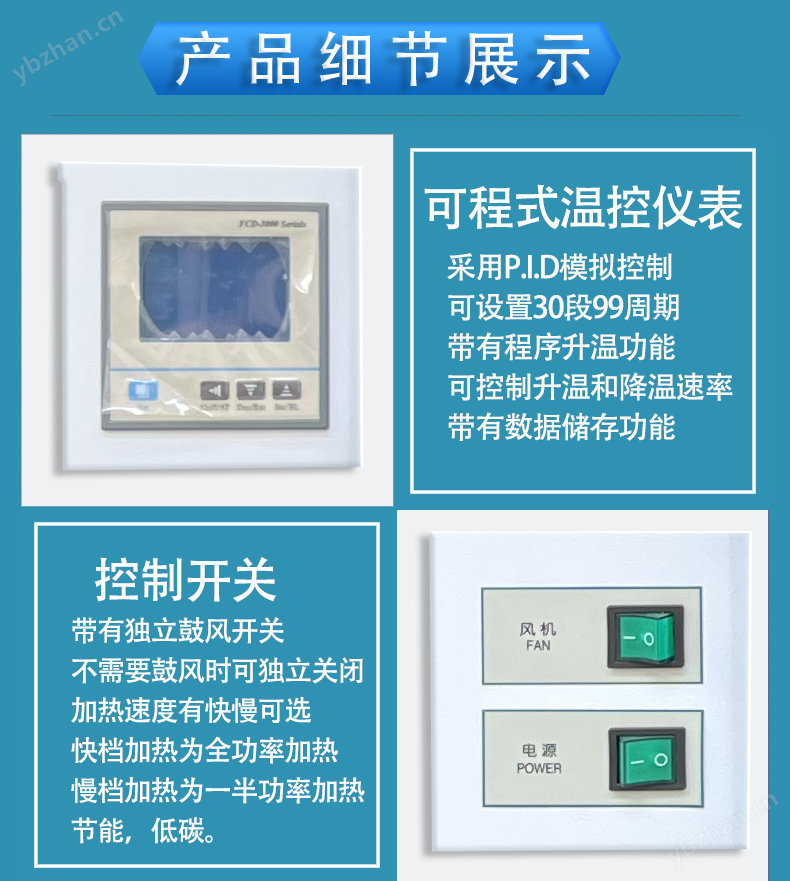

| Temperature Controller | Setting and monitoring temperature through digital or analog means, with high accuracy. |

| Safety protection device | Including over temperature protection, circuit breaker protection, etc., to ensure the safe operation of the equipment. |

The small desktop design takes up less space and is suitable for placement in experimental benches or fume hoods. In addition, the box door is usually equipped with an observation window, which facilitates users to view the sample status in real time without affecting the internal environment.

Application scenarios and practicality

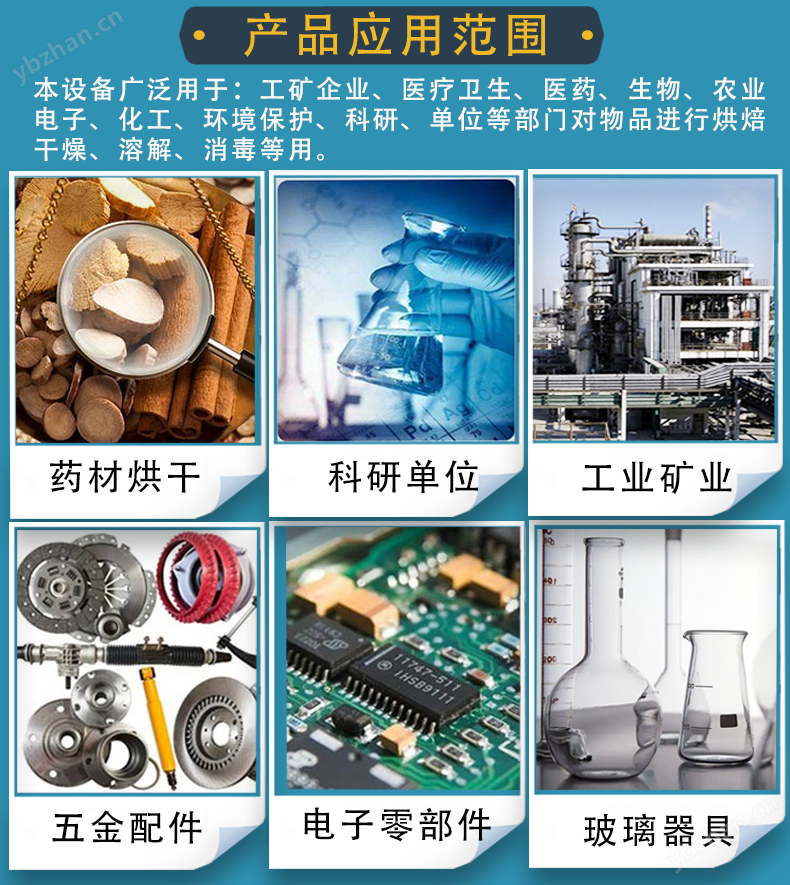

Small desktop electric blast drying ovens are widely used in multiple fields, including chemistry, biology, materials science, and pharmaceutical research and development. Here are several typical application scenarios:

Sample drying and solidification

In chemical experiments, many samples require removal of moisture or solvents at specific temperatures. For example, powder samples need to be weighed before weighingfullyDry to avoid moisture affecting measurement accuracy.Material heat treatment

Some polymer materials or metal samples require heating to change their physical properties, and a drying oven can provide a stable heat treatment environment.Drying of experimental vessels

After cleaning, glassware or experimental tools can be dried at low temperatures to avoid water stains and ensure cleanliness for the next use.Biological experiment pretreatment

Before microbial cultivation or tissue treatment, the culture medium or instruments often need to be dried and disinfected to eliminate potential contamination.

These applications demonstrate the flexibility and practicality of the device. Compared with large industrial drying equipment, small desktop drying ovens pay more attention to the convenience of operation and the controllability of the environment, making them suitable for small batch sample processing.

Precautions for use

To ensure long-term stable operation of the equipment, users need to pay attention to the following points:

Avoid exceeding the rated temperature range to avoid damaging the heating element or affecting the properties of the sample.

Regularly clean the space inside the box to prevent dust accumulation from affecting the efficiency of air circulation.

The placement location should be away from flammable materials and ensure good ventilation.

Conclusion

Laboratory small desktop electric blast drying ovenThrough its compact design, stable performance, and wide range of application scenarios, it has become a laboratory leadercrucialThe tools. Whether used for conventional drying or precision experimental pretreatment, it can provide reliable temperature control and uniform heating effect. In the future, with the advancement of technology, such devices may be further optimized in terms of energy efficiency and intelligence to better meet scientific research needs.