-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Laboratory sterilization dual-purpose electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1、 Equipment principle and core functions

Laboratory sterilization dual-purpose electric blast drying ovenGenerate thermal energy through electric heating elements and combine it with forced convection systems to achieve uniform temperature distribution. Its sterilization function relies on the destructive effect of high temperature environment on microorganisms, such as killing bacterial spores through dry heat sterilization method above 160 ℃. The core of the device lies inHot air circulation systemandPrecise temperature control technologyEnsure the controllability of sterilization and drying processes.

Problem introduction:

Why do laboratories need equipment with both drying and sterilization functions?

The answer is that in many experimental scenarios, samples or instruments need to be dried to remove moisture, and then sterilized at high temperatures to ensure sterility. For example, residual liquids need to be dried before sterilization of glassware to avoid temperature fluctuations or contamination caused by liquid evaporation at high temperatures.

2、 Key structural design

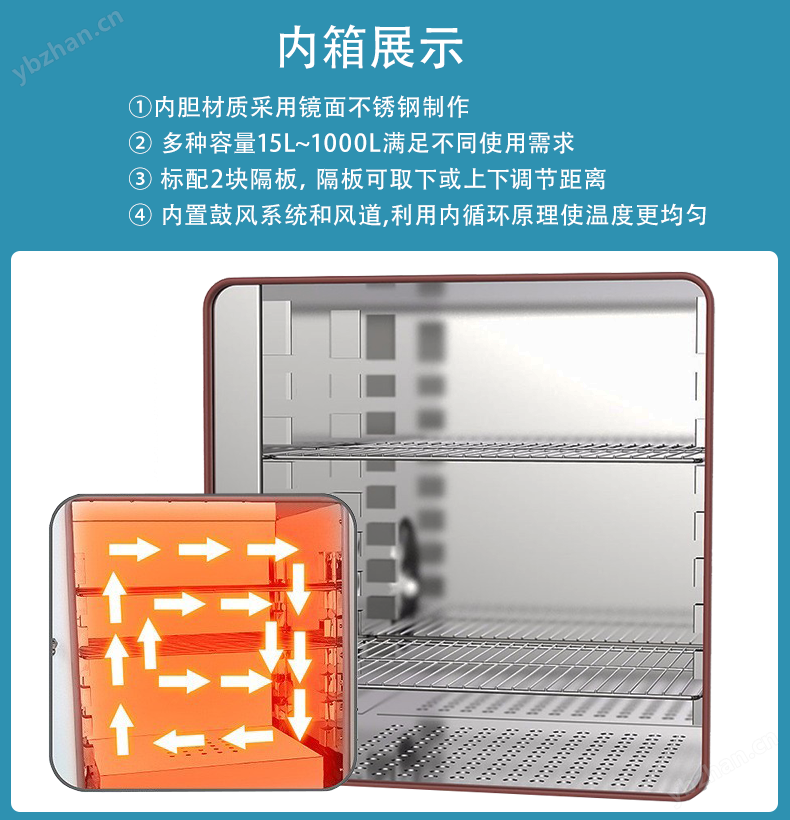

Hot air circulation system

Composed of high-temperature resistant fans and air ducts, the temperature uniformity inside the working room is achieved through horizontal or vertical airflow.

Some models use centrifugal fans to enhance airflow power and avoid excessive local temperature differences.

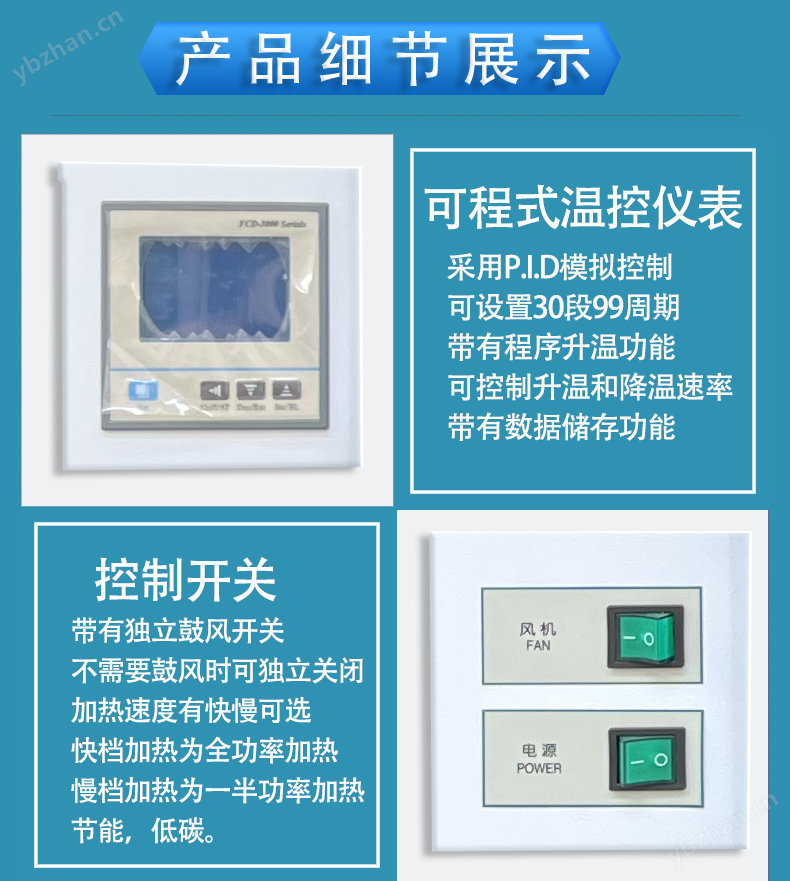

Temperature control and safety protection

The PID intelligent temperature control system can set a target temperature (such as 50-250 ℃) and provide real-time feedback adjustment, with an error range of usually ≤± 1 ℃.

The independent over temperature alarm device automatically shuts off when the temperature is abnormal, preventing sample damage or equipment failure.

Sterilization specific design

Sealing optimization: The box door adopts silicone rubber sealing strips to reduce external air interference.

Material corrosion resistance: The inner liner is made of mirror stainless steel, which is easy to clean and resistant to high temperatures.

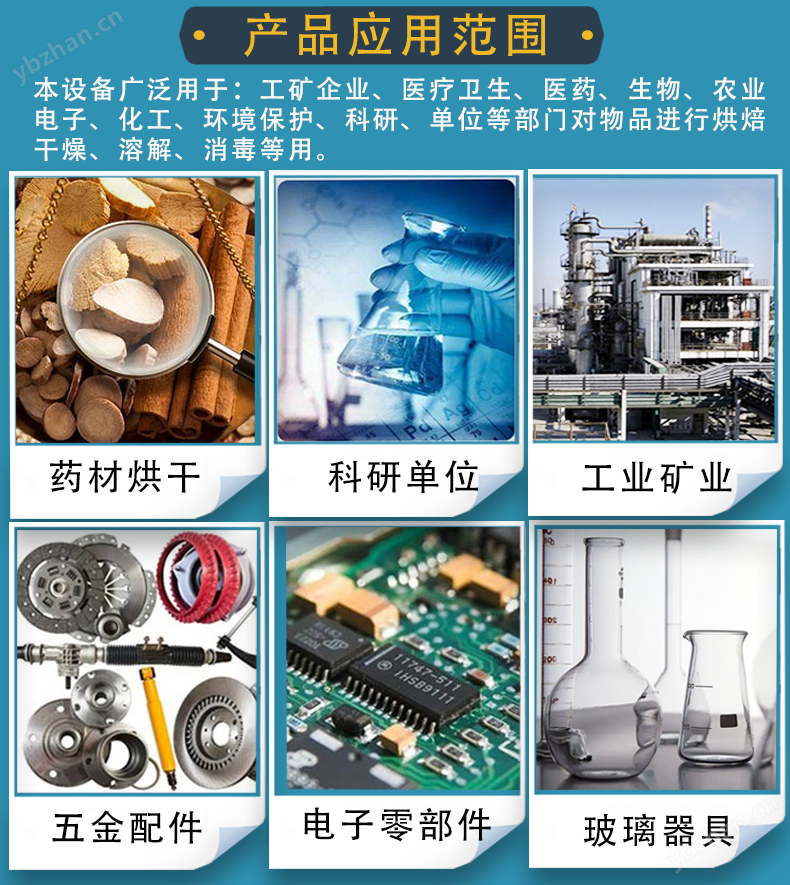

3、 Typical application scenarios

| Industry/Field | specific purpose |

|---|---|

| Biomedicine | Drying of pharmaceutical intermediates and sterilization of sterile equipment (such as culture dishes and pipettes) |

| food testing | Dehydration treatment of food samples and sterilization of packaging materials |

| Materials Science | Thermal stability testing of polymer materials and drying of nanoparticles |

| 高校科研 | Chemical reagent concentration, biological sample pretreatment |

Case Analysis:

In the microbiology laboratory, the culture medium needs to be sterilized at 160 ℃ for 2 hours after packaging. The traditional method requires drying the surface moisture of the culture medium in an oven before transferring it to sterilization equipment. The dual-purpose sterilization drying oven can directly complete the "drying sterilization" integrated process, reducing operational steps and pollution risks.

4、 Operation precautions

Temperature gradient control

During sterilization, it is necessary to gradually increase the temperature (such as from room temperature to the target temperature) to avoid sudden heating that may cause sample explosion or thermal stress damage to equipment components.

Load distribution

Place the samples evenly to ensure smooth airflow and avoid stacking affecting heat transfer efficiency.

Cleaning and maintenance

Regularly clean the fan blades and filter screen to prevent dust accumulation and reduce cycle efficiency.

5、 Selection suggestions and development trends

Problem introduction:

How to choose a suitable sterilization dual-use drying oven based on laboratory needs?

Capacity matchingSmall laboratories can choose desktop models (such as working sizes of 350 × 350 × 350mm), while large production scenarios require vertical high-capacity models.

function extensionSome devices support program temperature control (such as preset temperature rise constant temperature drop curve), which is suitable for complex process requirements.

6、 Conclusion

Laboratory sterilization dual-purpose electric blast drying ovenBy combining thermodynamics with automation control, efficiency can be improved while ensuring experimental accuracy. Its application has expanded from traditional drying to multiple fields such as sterilization and aging testing, becoming a key factor in scientific research and industrial productioncrucialThe tools. Understanding its principles and usage guidelines can help fully unleash the potential of the equipment and ensure experimental safety.