-

E-mail

info@jscmkj.com.cn

-

Phone

18112375870

-

Address

No. 19 Hefeng Road, Xinwu District, Wuxi City, Jiangsu Province

Jiangsu Chenming Technology Co., Ltd

Measurement inside pipelines using the intelligent dew point probe DMP6 in high-temperature applications

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

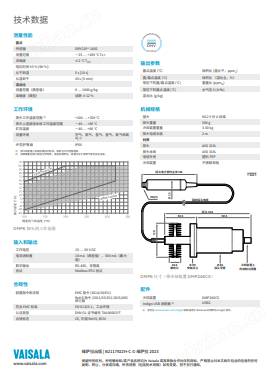

Vaisala DRYCAP ® The intelligent dew point and temperature probe DMP6 is designed for low humidity measurement inside pipelines in industrial drying applications with high temperatures and wide dew point ranges. Using a natural cooling device to achieve high temperature resistance, this device takes away the heat from the probe and lowers the temperature to within the suitable measurement range of the sensor.

DRYCAP®

DMP6 combines stable, accurate, and reliable Vaisala DRYCAP ® Sensors are not affected by particles, condensed water, oil mist, and most chemicals. The heating function of the sensor greatly reduces the accumulated condensation risk on the sensor. If DRYCAP ® The sensor is damp, it can quickly dry and restore a fast response time. In low humidity environments, the sensor will automatically calibrate to ensure accurate measurements.

The intelligent DMP6 belongs to the Indigo series products and is compatible with Indigo500 and Indigo200 transmitters. It can be used together with Vaisala Insight computer software to achieve data visualization, easy probe configuration, and self calibration.

feature

Measure humidity inside the pipeline at temperatures up to+350 ° C (+662 ° F)

The dew point measurement range is -25...+100 ° C (-13...+212 ° F) Td

Dew point measurement accuracy up to ± 2 ° C (± 3.6 ° F)

Sensor clearing provides good chemical resistance

Resistant to condensation, oil stains, dust, and most chemicals

Supports Modbus RTU communication protocol with RS-485, providing diverse and flexible connection methods

Compatible with Indigo series transmitters

Including traceable 3-point calibration certificates

Calibration interval of up to two years, reducing maintenance workload

main advantages

Directly measuring dew point during high-temperature processing

The intelligent DMP6 is designed for measuring dew points in pipelines during high-temperature processing (100... 350 ° C (+662 ° F)). Reliable measurement performance can be achieved at process temperatures between 100 ° C and 350 ° C. The cooling system has no moving parts and does not require additional power or cooling devices, so it will not cause sensor damage due to mechanical cooling failures.

Easy to install, as the probe can be directly placed during the machining process. When measuring inside the pipeline, there is no need for a sampling system or heating of the sampling pipeline.

Vaisala DRYCAP for accurate and reliable measurements ® sensor

Vaisala DRYCAP ® The sensor is stable, accurate, and reliable, unaffected by particles, oil mist, and most chemicals. The heating function of the sensor greatly reduces the accumulated condensation risk on the sensor. If DRYCAP ® The sensor is damp, it can quickly dry and recover. The automatic calibration function ensures accurate and stable measurements.

Chemical removal involves regularly heating sensors to eliminate harmful chemicals. In environments with high concentrations of chemicals and cleaning agents, the chemical removal function helps maintain measurement accuracy during calibration cycles.

Used independently or in conjunction with Indigo transmitters

The intelligent DMP6 belongs to the Vaisala Indigo series products, so it can also be used with the Vaisala Indigo200 transmitter. These transmitters also have other features, such as a display screen that visually displays data, easy access for probe configuration, and more options for automation system connection, power supply voltage, and wiring.

The Modbus RTU communication protocol with built-in RS-485 means that DMP6 can be used as a standalone device or easily integrated into third-party systems.

When using DMP6 independently or in conjunction with Indigo transmitters, it can be connected to the Vaisala Insight computer software for easy on-site calibration, probe configuration, and device analysis.