-

E-mail

xaslck@163.com

-

Phone

18802933690,18829593940

-

Address

Xi'an High tech Zone New Industrial Park

Xi'an Sanlian Measurement and Control Technology Co., Ltd

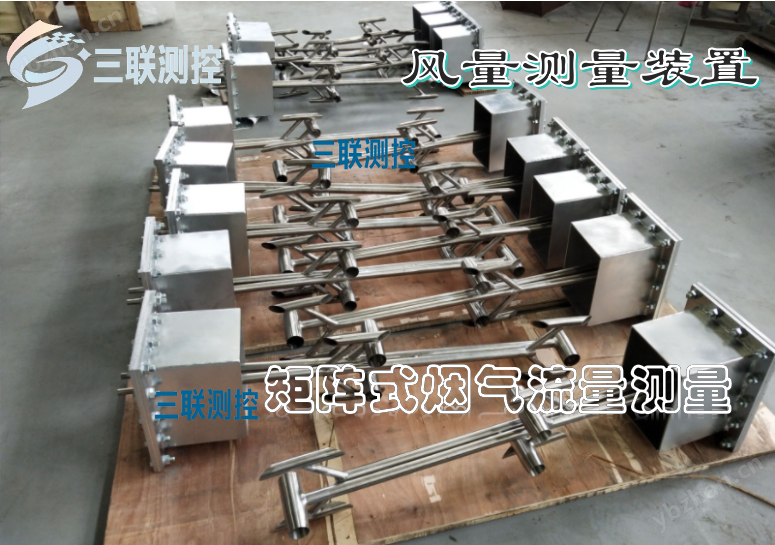

Multi point matrix gas flowmeter

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Introduction to the principle of multi-point anti blocking matrix air volume measurement device

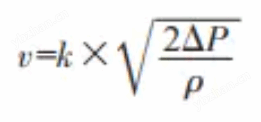

The SLFS series triple measurement and control anti blocking matrix air volume measurement device has a sampling part inserted into the pipeline. When the airflow passes through the sampling device, the sampling tube on the windward side is impacted by the airflow in the pipeline, resulting in a higher pressure inside the sampling tube on the windward side. The sampling on the leeward side comes from the static pressure inside the air duct. The difference between the two sides is called differential pressure, and the magnitude of the differential pressure value is related to the wind speed of the fluid in the air duct. The relationship between flow rate and sampling differential pressure is as follows:

Measurement characteristics:

Strong anti blocking performance

The improved sensor has made great breakthroughs in the pressure measurement point, fully considering the current widespread use status. Single point measurement has become multi-point measurement, and the design of multiple pressure holes, pressure points, and pressure directions has increased the anti blocking performance of the product, achieving no blowing and maintenance.

■ High output differential pressure

In the process of dynamic pressure measurement, when the pressure remains constant, the acceleration suction effect of the throat tube is used to reduce the negative pressure to the minimum limit, greatly improving the differential pressure range. The characteristics are particularly prominent in flow measurement under conditions of large caliber, low static pressure, and low pressure loss.

■ Stable differential pressure signal without pulsation

Through the rectification effect of the contraction section and the pressure ring, the pulsation signal is maximally eliminated.

■ Wide measurement range

Can be used for measuring dry, humid gases, liquids, and vapor media without being limited by dielectric constant. For the measurement of high-density dust substances, only regular use of online blowing devices is required, ensuring flexible application in various working conditions.

Low requirements for straight pipe sections

The multi-point and multi-faceted pressure tapping method effectively balances the uniformity of pressure in the pipeline; The cold simulation experiment shows that satisfactory measurement results have been obtained with a front straight pipe section of 1D and a rear straight pipe section of 0.5D.

Application fields:

Industrial boiler flue gas emission online monitoring system, chemical, metallurgical, food, chemical fiber and other industries, as well as measurement of gas flow in boiler primary and secondary air and large-diameter pipelines.

Evaluation of multi-point anti blocking matrix air flow measurement device after use

(1) Good linearity and repeatability, high measurement accuracy. Plug in installation, optimized installation of triple measurement and control, flange installation is convenient, and the insertion depth runs through the entire air duct.

(2) Multiple uniformly distributed sampling pipelines are used to achieve average pressure measurement across the entire cross-section of the pipeline, improving the accuracy of the measurement.

(3) Due to the rectification effect of the rectifier tube of the device itself and the grid Fabry Perot points, even if the straight pipe section of the air duct is short, accurate measurement can still be achieved. Xi'an Sanlian Measurement and Control has conducted multiple wind tunnel experiments to ensure the reasonable distribution of points.

(4) An iron rod is suspended in both the high and low pressure sampling pipelines of the measuring device. When the air volume changes, the iron rod can be driven to strike the sampling device, effectively reducing the accumulation of dust inside the sampling chamber and further extending the blowing cycle of thermal personnel.

(5) The device has a flow direction correction method, which can be used for measurement in short straight pipe sections and irregular surfaces inside the air duct.

(6) The device itself has wind shear turbulence resistance means, and the signal outlet is equipped with a pressure equalization box, which can make the measurement signal stable and have small fluctuations.

(7) The device has good anti vibration performance, and in response to the objective reality of vibration in the actual operation of the air duct, it can ensure that the actual measurement accuracy on site is not reduced.

(8) The sampling area inside the air duct of this device is very small, so there is almost no resistance to the airflow inside the duct, which has a certain energy-saving effect