-

E-mail

lixin@yunjingtianhe.com

-

Phone

15666887396

-

Address

Room 206, Building 1, Weifang High tech Zone Optoelectronic Industry Accelerator (Phase I), No. 155 Optical Circuit, Weifang High tech Zone, Shandong Province

Shandong Tianhe Environmental Technology Co., Ltd

Photovoltaic power plant dust detection system

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Photovoltaic power plant dust detection systemIt is an intelligent monitoring device designed specifically for photovoltaic power plants. Through high-precision sensors and advanced measurement technology, it can sense the degree and distribution of dust coverage on the surface of photovoltaic panels in real time, helping operation and maintenance personnel to accurately formulate cleaning plans and improve power generation efficiency and economic benefits. The system measures the dust coverage on the surface of photovoltaic panels in real-time through high-precision sensors, including key parameters such as dust volume, dust particle size distribution, and reflectivity. By utilizing the Blue Light Pollutant Optical Closed Loop Measurement (OMBP) technology, the transmission loss caused by pollutants on glass is continuously monitored, accurately capturing subtle changes in dust coverage. By quantifying the proportion of pollutants (SR), the real-time conversion of dust coverage into intuitive data on power generation loss helps operation and maintenance personnel clearly understand the impact of dust on power generation. When the dust coverage exceeds the preset threshold, the system automatically triggers a warning signal to prompt operation and maintenance personnel to clean and maintain in a timely manner. Supporting remote monitoring function, operation and maintenance personnel can view real-time dust data, SR values, and power generation losses of each monitoring point through computer terminals or mobile apps, without the need for frequent on-site inspections. The intelligent decision support system can automatically analyze the impact of dust accumulation on power generation efficiency, predict the trend of dust accumulation based on meteorological data, and provide scientific decision-making basis for operation and maintenance personnel. Support docking with intelligent cleaning robots to achieve data sharing and linkage control, and improve cleaning efficiency.

1、 Product Overview

The pollutants on the glass of solar modules are one of the main issues that rapidly affect photovoltaic power plants, reducing power generation efficiency and cost-effectiveness. The use of blue light pollution closed loop measurement (OMBP) technology can easily be installed in new or existing photovoltaic arrays and integrated into power plant management systems. The device is installed on the frame of the photovoltaic panel. By continuously measuring the transmission loss caused by pollutants on the glass, the reduction in sunlight reaching the solar module can be calculated.

By measuring the proportion of pollutants (SR), it is converted into real-time loss of power generation. This allows operation and maintenance personnel to know when pollutants reach the critical point and when it is necessary to start the cleaning process. This product does not require maintenance and only needs to be cleaned in the same way when cleaning surrounding components.

Due to the varying pollution rates of large photovoltaic power plants throughout the entire park, the IEC 61724-1 standard requires multi-point measurement. Compared to traditional systems, it has much lower procurement, installation, and maintenance costs, making it more economical, so cleaning can be planned at the time and place needed.

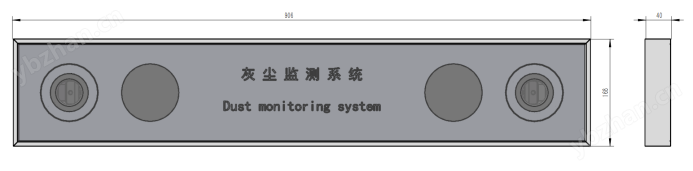

2、 Product appearance dimensions

3、 Main functions and features

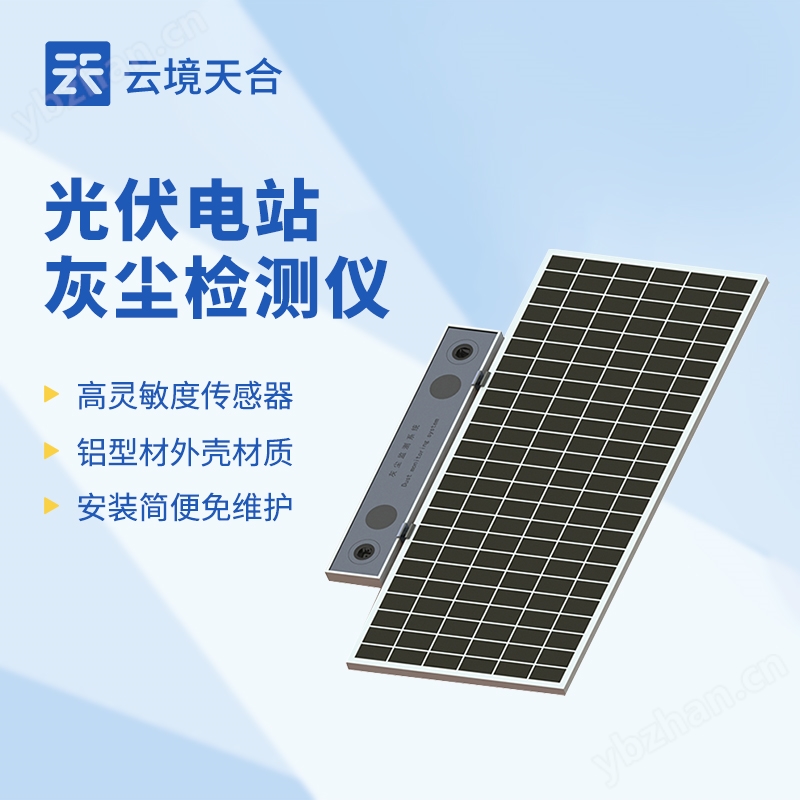

Main function: Dust monitoring system, mainly used for dust monitoring of photovoltaic equipment, helping photovoltaic equipment achieve real-time and remote monitoring of dust. When the cleanliness of the photovoltaic panel surface is insufficient, it prompts users to clean it in a timely manner to reduce energy loss and improve power generation efficiency.

Product features: The photovoltaic dust monitoring system is equipped with high-sensitivity sensors, which can accurately monitor the dust situation on the surface of photovoltaic panels. It has dust-proof design and easy installation without maintenance, and can operate stably in harsh environments.

Equipment description: The photovoltaic dust monitoring system is a device used to monitor the dust coverage on the surface of photovoltaic panels. It is mainly used to improve the efficiency of photovoltaic power generation and maintain the photovoltaic system. Its main functions and product features make it an important auxiliary equipment in the photovoltaic power generation system, helping users clean the photovoltaic panels in a timely manner, improve power generation efficiency, and extend the service life of the photovoltaic system.

4、 Technical parameters

| Product model parameters | HS1 |

| power supply voltage | DC 12V |

| average power | 1W |

| Instantaneous maximum power | 2.5W |

| Range of smoothness measurement | 50%~100% |

| resolution | 0.5% |

| accuracy | 1% |

| Operating Temperature | -50℃~+80℃ |

| Operating Humidity | 30%-70% |

| Storage temperature | -20~65℃ |

| Protection level | IP65 |

| Product weight | 3.65KG |

| Product volume | 906*168*40mm |

| output method | RS485 |

| communication protocol | Modbus |

| Baud rate | Default 9600, adjustable |

| Shell material | aluminum profile |

| power cord length | 20m |

| Communication line length | 20m |

5、 Instructions for use

Connect the device according to the wiring instructions (except for the power input and 485 communication output ports, all other peripheral devices have been connected at the factory). After connecting the 12V power supply, the host or acquisition device can be used for communication.

6、 Equipment installation

Preparation before installation:

Dust monitoring system equipment, dust monitoring solar connector A * 4, dust monitoring solar connector B * 4, screw and nut M8 * 70 kit * 4.

Installation description:

This device needs to be installed in conjunction with the photovoltaic panel. After preparing for installation, the dust monitoring device should be placed parallel to the solar photovoltaic panel, with the glass surface facing the light receiving surface of the solar panel. The dust monitoring solar connector A should be placed in an inverted shape between the solar panel and the dust monitoring system device, and the dust monitoring solar connector B should be placed at the bottom of the device. Use M8 screws and nuts to penetrate and tighten, and repeat the steps to fix the installation at multiple points.