-

E-mail

9066726@qq.com

-

Phone

13855058800

-

Address

No. 20 Renhe South Road, Tianchang City, Anhui Province

Product Categories

Anhui Tiankang (Group) Co., Ltd

Platinum thermistors for hydropower stations

NegotiableUpdate on 01/11

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

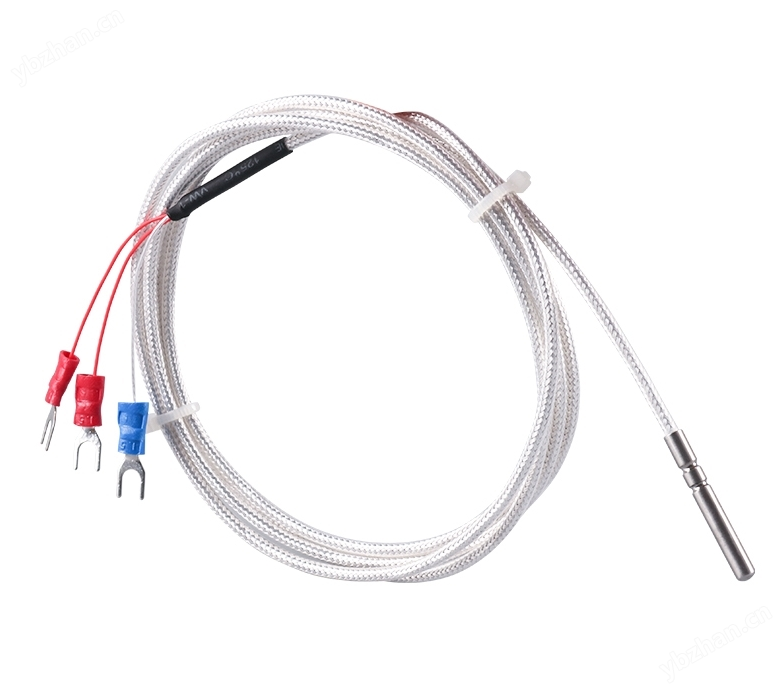

The platinum thermistor of the hydropower station adopts armor wire produced by a specialized German factory. This armor wire is made through a process of high-purity magnesium oxide filling, high-temperature drying, drawing, rolling, and annealing

Product Details

Our company uses the HST thin film technology produced by Heraeus Sensor Technology as the sensor element to ensure the seismic resistance and stability of the product. The Agpd lead and stainless steel protective tube of the platinum thermistor in the hydropower station are hydraulically packaged and protected with 304 corrugated pipe to ensure the durability of the product.

The platinum thermistors used in hydropower stations are made of armor wire produced by specialized German factories. This armor wire is filled with high-purity magnesium oxide, dried at high temperatures, drawn, rolled, and annealed. Its characteristics are long service life, fast response speed, high mechanical strength, and good insulation. Do not use a tail connector structure for temperature measuring resistors used for tile temperature and tile oil temperature.

Platinum thermistors for hydropower stations can be used to measure temperatures within the range of -50 to 450 ℃, and can be directly connected to secondary instruments using copper wires. Due to its excellent electrical output characteristics, it can provide accurate temperature change signals for displays, recorders, regulators, scanners, data loggers, and computers.

Similar Product Recommend