-

E-mail

ebauto18@126.com

-

Phone

13361831617

-

Address

No. 1909 Cao'an Road, Jiading District, Shanghai

Shanghai Yibi Automation Instrument Co., Ltd

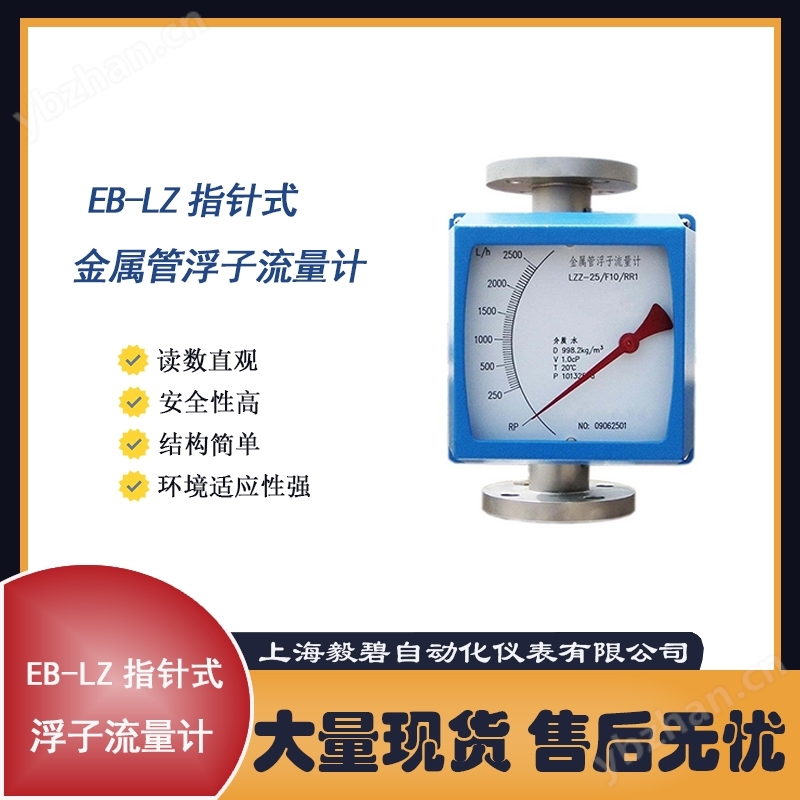

Pointer type metal tube float flowmeter

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

In the field of small and medium-sized flow measurement in industry, pointer type float flowmeter has become a commonly used equipment for monitoring the flow of media such as water, gas, and light oil due to its advantages of simple structure, intuitive reading, and low cost. It is widely used in chemical, environmental protection, food, laboratory and other scenarios. It is designed based on the principle of "float force balance", displaying flow values directly through pointers without the need for complex electronic components. It can meet the basic flow monitoring needs and adapt to working conditions without power supply and small space on site, making up for the cost and installation limitations of intelligent flow meters in simple scenarios.

1、 Core advantage: Adapting to the characteristics of small and medium-sized traffic

Intuitive and easy to read, with low operational thresholdThe display method adopts a combination of mechanical pointers and dials, and the flow value is read in real time by the pointer pointing to the scale, without the need for power on or complex operations. Workers can master it through simple training, especially suitable for on-site inspections, temporary monitoring and other scenarios, avoiding the threshold of learning the operation interface of smart instruments.

Simple structure and controllable costWithout complex electronic components and communication modules, the core components consist only of conical tubes, floats, and pointer mechanisms. The manufacturing cost is much lower than that of intelligent vortex street and turbine flow meters, and the procurement cost is usually only 1/3 to 1/5 of that of intelligent instruments of the same caliber. In addition, there are no additional expenses such as software maintenance and battery replacement in the later stage, making it suitable for scenarios with limited budgets or only requiring basic measurements.

Suitable for small and medium traffic, with minimal pressure lossSpecially designed for small and medium flow rates (usually ranging from 0.1 to 100m ³/h), it can accurately measure small flow rates as low as 0.01m ³/h (such as laboratory reagent delivery), and the structure design of the conical tube and float ensures minimal fluid pressure loss (usually ≤ 5kPa), which will not affect the normal operation of low-pressure systems (such as vacuum pipelines and small pump delivery systems).

Strong environmental adaptabilityWithout electronic components, it is not affected by electromagnetic interference or power fluctuations, and can work stably in strong magnetic fields (such as near motors), humid environments (IP65 protection level), and without power (such as outdoor remote sampling points). Some models use corrosion-resistant materials (such as polytetrafluoroethylene and stainless steel), and can also adapt to acid and alkali corrosive media measurement.

2、 Working principle: Measurement logic for force balance of float

Fluid drives the float to riseThe main body of the instrument is a conical tube (mostly made of glass, metal, or plastic) with an inner diameter gradually increasing from bottom to top. A freely movable float (material selected according to the density of the medium, such as metal float for liquid measurement and plastic float for gas measurement) is placed inside the tube. When fluid flows in from the bottom of the conical tube, it exerts an upward thrust on the float, overcoming its own gravity and fluid resistance, and pushing the float upwards.

Float position corresponds to flow rateAs the float rises, the annular flow area between the inner wall of the conical tube and the float gradually increases, the fluid velocity decreases, and the upward thrust on the float decreases accordingly. When the upward thrust reaches equilibrium with the weight of the float and fluid resistance, the float stops moving and stabilizes at a certain position. Due to the fixed correspondence between the annular flow area and the flow rate (the higher the flow rate, the higher the equilibrium position), the height of the float can directly reflect the size of the fluid flow rate.

Pointer mechanism conducts readingsThe float is connected to the pointer mechanism outside the tube through magnetic coupling or mechanical linkage (magnetic coupling is commonly used for glass tubes to avoid fluid leakage; mechanical linkage is commonly used for metal tubes). The up and down movement of the float synchronously drives the pointer to rotate, and the pointer points to the corresponding flow rate value on the dial, achieving intuitive reading of the flow rate. The dial usually indicates the volume flow unit (such as L/h, m ³/h), and some models can also customize special range scales according to user needs.

3、 Structure composition and classification: adapted to different scene requirements

(1) Core structural components

tapered tubeDetermine the range of flow measurement and compatibility with the medium. Glass tubes have good transparency, making it easy to observe the state of the float. They are suitable for clean, non corrosive media such as water and air; Metal pipes (stainless steel, Hastelloy) are pressure resistant and corrosion-resistant, suitable for high pressure (≤ 2.5MPa) and corrosive media (such as acid and alkali solutions); Plastic pipes (polytetrafluoroethylene) are lightweight and cost-effective, suitable for low-pressure, highly corrosive chemical environments.

floatIt needs to match the density of the medium to ensure stable force balance. High density metal floats (such as copper and stainless steel) are commonly used for measuring liquids to avoid excessive lifting of the float by the buoyancy of the liquid; Low density plastic or hollow metal floats (such as aluminum floats) are commonly used for gas measurement to ensure that the gas thrust can push the float up; For measuring corrosive media, a polytetrafluoroethylene float is used.

Pointer and dialThe pointer needs to have clear directionality, and the scale of the dial needs to be accurately calibrated (through real flow calibration before leaving the factory). Some models come with a zero adjustment knob that can correct reading deviations caused by installation tilt (≤ 5 °), ensuring measurement accuracy (conventional accuracy ± 2.5% FS, high-precision models can reach ± 1.5% FS).

(2) Mainstream classification

According to the material of the conical tube:

Glass tube pointer float flowmeter: good transparency, low cost, suitable for atmospheric pressure and clean media (such as laboratory water, compressed air), but low pressure resistance (≤ 0.6MPa), fragile, and need to avoid impact.

Metal tube pointer type float flowmeter: high pressure resistance (≤ 4.0MPa), corrosion resistance, suitable for high-pressure and corrosive media in industrial sites (such as chemical acid and alkali solutions, oilfield associated gas), but cannot directly observe the float status and needs to be judged by the pointer.

According to installation method:

Vertical installation type: The most common type requires ensuring that the conical tube is vertical (inclination ≤ 5 °) and the fluid flows from bottom to top, suitable for pipeline type fixed measurement (such as workshop process pipelines).

Horizontal installation type: The conical tube is placed horizontally, and the float achieves measurement by balancing the horizontal force. It is suitable for scenarios with limited space and inability to install vertically (such as internal pipelines of equipment), but the measurement accuracy is slightly lower than that of the vertical type.

4、 Key selection points and industry applications

(1) Key points of selection

Media adaptationChoose conical tube and float material based on the type of medium (liquid/gas, corrosive/clean) - choose metal tube+PTFE float for corrosive medium, glass tube+stainless steel float for cleaning liquid, and glass tube+plastic float for gas.

flow rangeChoose an instrument with a full range of 1.2 to 1.5 times the actual maximum flow rate, ensuring that the float operates within the range of 20% to 80% of the dial (to avoid low range accuracy and damage to the float due to exceeding the range). For example, if the actual maximum flow rate is 10m ³/h, a model with a full range of 15m ³/h can be selected.

operating conditions parametersConfirm that the temperature and pressure of the medium do not exceed the rated value of the instrument (glass tubes usually have a temperature resistance of ≤ 120 ℃ and a pressure resistance of ≤ 0.6MPa); Metal pipes with a temperature resistance of ≤ 200 ℃ and a pressure resistance of ≤ 2.5MPa should be selected, and special models for high temperature and high pressure should be chosen if they exceed the range.

Installation requirementsPrioritize vertical installation type to ensure sufficient vertical space at the installation location; When there is no vertical space, choose the horizontal installation type and confirm that the pipe diameter matches the instrument connection method (thread/flange).

(2) Typical Industry Applications

Laboratory SceneGlass tube pointer float flowmeter (range 0.1~10L/h) is used for small flow control of reagents and gases in chemical experiments, such as monitoring the flow rate of carrier gas in chromatography. The intuitive reading is convenient for adjusting experimental parameters.

environmental protection industryMetal tube pointer type float flowmeter (corrosion-resistant material) is used in the chemical dosing system of sewage treatment plants to measure the dosing flow rate of coagulants such as PAC and PAM, ensuring stable chemical concentration and improving sewage treatment efficiency.

food industrySanitary grade stainless steel pointer type float flowmeter is used for raw material transportation in beverage and dairy production, such as flow monitoring of syrup and purified water, to meet food hygiene standards (such as 3A certification) and avoid contamination risks.

chemical industryPTFE material pointer type float flowmeter is used in acid-base solution transportation pipelines to measure the flow rate of hydrochloric acid and sodium hydroxide solutions. It is suitable for strong corrosion conditions and does not require a power supply, making it suitable for outdoor dosing points.

5、 Maintenance points: Ensure long-term stable operation

regular cleaningCheck the conical tube and float every 3-6 months, clean the impurities (such as scale and oil stains) attached to the inner wall, and avoid the float getting stuck and causing inaccurate readings; Glass tubes can be wiped with a soft cloth dipped in alcohol, while metal tubes can be cleaned by disassembling the float.

Installation CheckRegularly check whether the instrument installation is vertical (vertical type), whether the connection part leaks, and adjust and tighten it in a timely manner if tilting or leakage is found to avoid affecting measurement accuracy or causing medium leakage.

Avoid overload and impactIt is strictly prohibited to use beyond the range. When starting the pump valve, it should be slowly opened to avoid fluid impact damaging the float; The glass tube model should avoid collisions and sudden temperature changes (such as alternating cold and hot media) to prevent the glass tube from breaking.