-

E-mail

2623729929@qq.com

-

Phone

13871140023

-

Address

Baishazhou Fenghuo Steel Market in Hongshan District, Wuhan City

Wuhan GeTe Electromechanical Equipment Co., Ltd

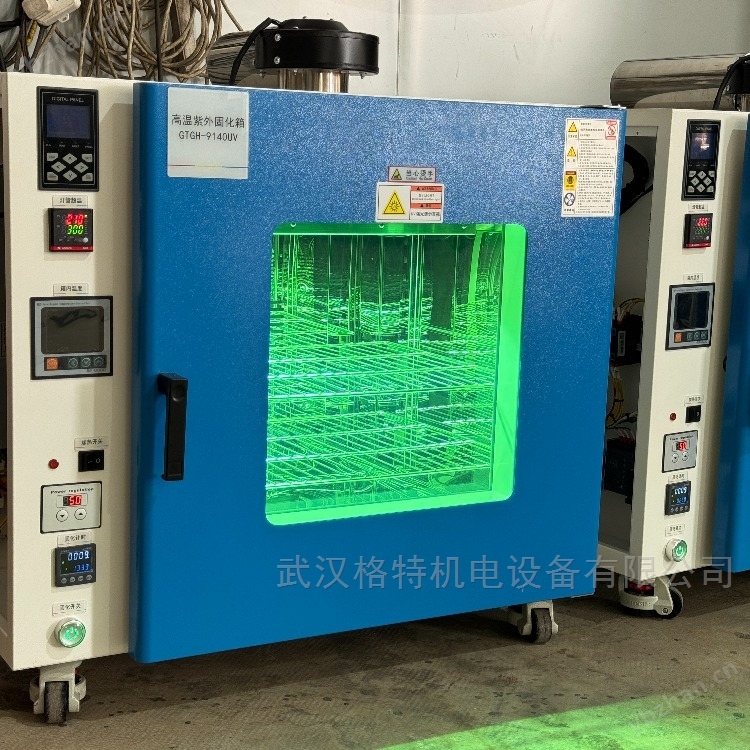

Production of high-temperature UV curing box

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Detailed Introduction to High Temperature UV Curing Box

1. Product Overview

Production of high-temperature UV curing boxIt is a specialized equipment that combines ultraviolet (UV) curing and high-temperature heating technologies, mainly used to accelerate the curing process of photosensitive materials such as coatings, inks, adhesives, etc. By using high-intensity UV light sources and controllable temperature heating systems, the curing efficiency and product quality are significantly improved, and it is widely used in industries such as electronics, printing, coatings, and 3D printing.

2. Core functions and features

Dual solidification mode:

UV curing: Equipped with high-power UV lamps (such as mercury lamps, LED UV lamps), with a wavelength range covering 280-405nm, it can quickly trigger the reaction of luminescent initiators.

High temperature assistance: The heating system (usually adjustable between 50-200 ℃) promotes deep curing and solves the problem of inadequate curing in shaded areas or thick coatings.

Precise temperature control:

PID intelligent temperature control technology controls the temperature difference within ± 2 ℃ to avoid material deformation or uneven curing due to overheating.

Uniform illumination:

Reflective cavity design or multi light source layout to ensure UV irradiation uniformity (can be monitored with a digital radiometer).

Security protection:

The safety design includes anti UV leakage windows, over temperature protection, and automatic power-off, which comply with industrial equipment standards.

Flexible configuration:

Customizable conveyor belt (continuous curing), inert gas environment (anti-oxidation), different UV wavelength modules, etc.

3. Typical application scenarios

Electronics industry: PCB solder mask curing, chip packaging UV glue curing.

Printing and packaging: UV ink and metal coating dry quickly.

Automobile manufacturing: curing of car lamp adhesive, interior coating treatment.

Research field: Curing performance testing of new materials (such as photosensitive resins).

4. Production of high-temperature UV curing boxExample of Technical Parameters

|Project | Parameter Range|

|---------------|--------------------------|

|UV wavelength | 365nm/395nm (optional)|

|Power | 1-5kW (customized according to cavity size)|

|Temperature range | Room temperature -200 ℃ (adjustable)|

|Curing time | 10 seconds -10 minutes (programmable)|

|Chamber size | Customized according to requirements (from small to assembly line)|

5. Selection suggestions

According to material requirements: Select a matching UV wavelength (such as 365nm, which is suitable for most photoinitiators).

Capacity matching: For continuous production, conveyor belt models need to be selected, and desktop models can be used for small batch experiments.

Safety certification: Confirm that the equipment complies with CE, RoHS and other standards, especially for export purposes.

6. Precautions

Avoid prolonged exposure to UV light sources and wear protective goggles during operation.

Regularly clean the reflector and lamp tube to maintain optimal curing effect.

Ensure ventilation during high temperature operation to prevent the accumulation of volatile substances.

If further technical solutions or customized requirements are needed, material samples and process parameters can be provided, and professional personnel can adapt the equipment configuration for you.