The high and low temperature test chamber can simulate aging tests in a humid and hot environment, which can meet the testing needs of multiple industries such as electronic appliances, automotive parts, plastic hardware, medical devices, textiles, and food, such as high and low temperature reliability testing of electronic components, humid and hot aging testing of automotive parts, and temperature and humidity storage stability testing of food.

Programmable humidity and heat environment simulation aging test in high and low temperature test chamber

Inner box materialSUS # 304 stainless steel plate has good corrosion resistance and high temperature and humidity resistance, which can effectively resist corrosion in temperature and humidity environments without causing pollution to the testing environment.

outer box materialThe outer box mainly serves the functions of protection and insulation. Steel plate baking paint material is commonly used, with a thickness of about 1.0mm. This material not only has a certain strength, but also the baking paint treatment can enhance aesthetics and rust prevention performance.

thermal insulation materialHigh quality insulation materials are the key to maintaining stable temperature and humidity inside the box, and the combination of hard polyurethane foam and glass wool is a common and effective insulation method

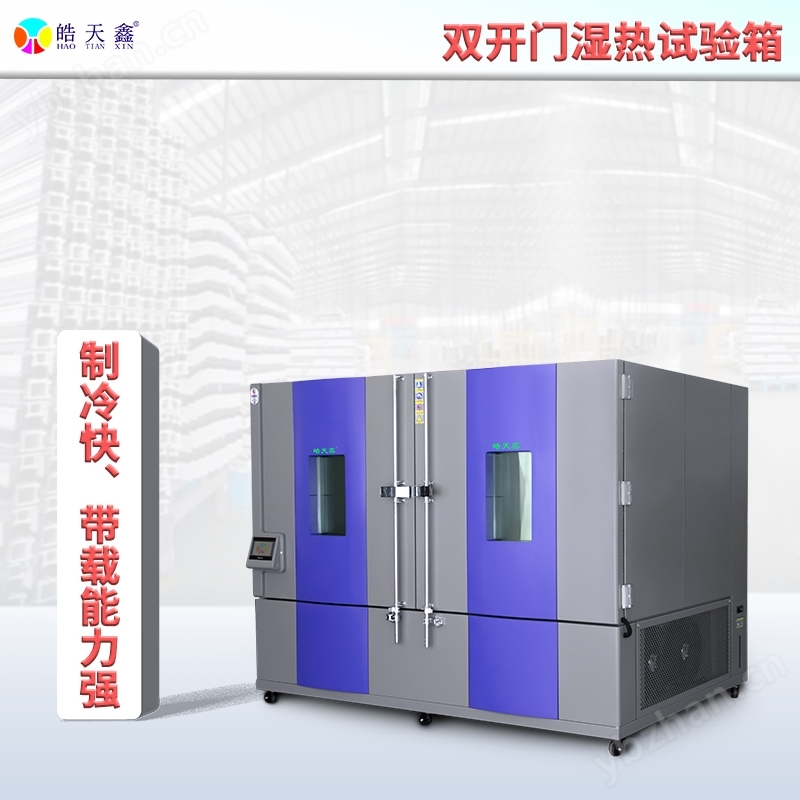

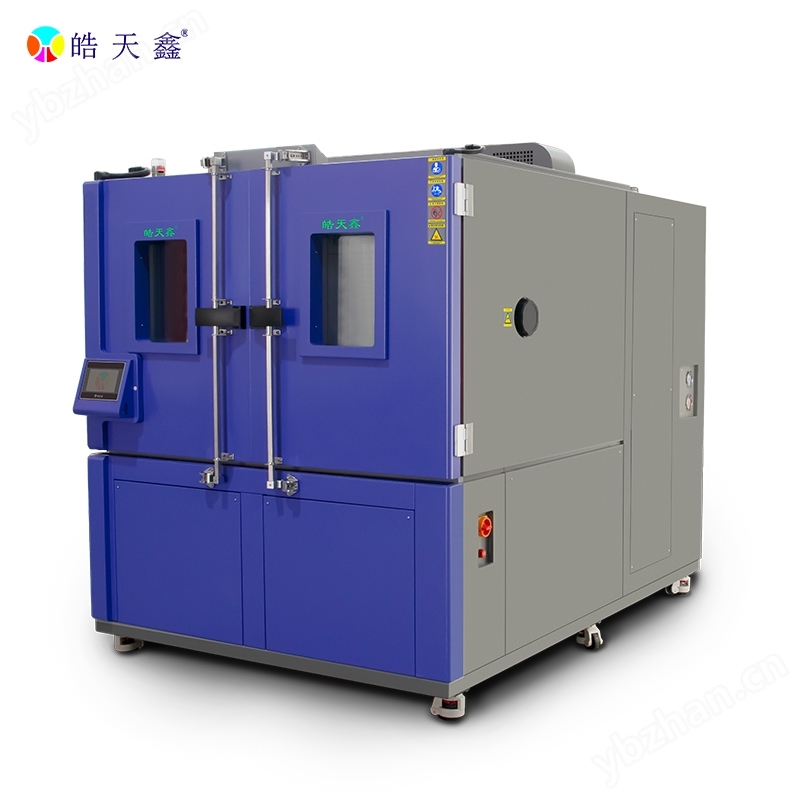

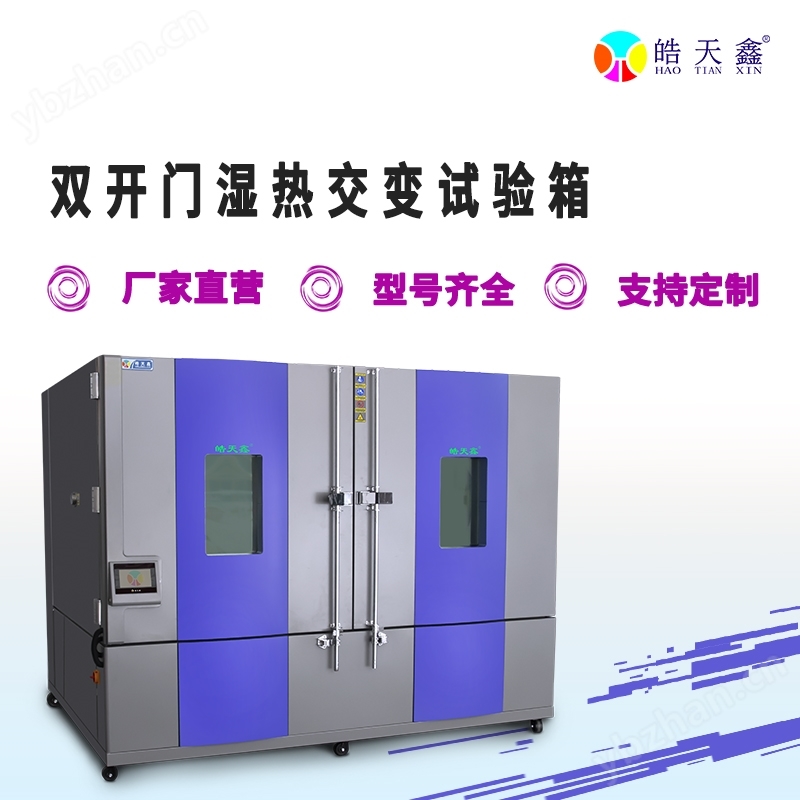

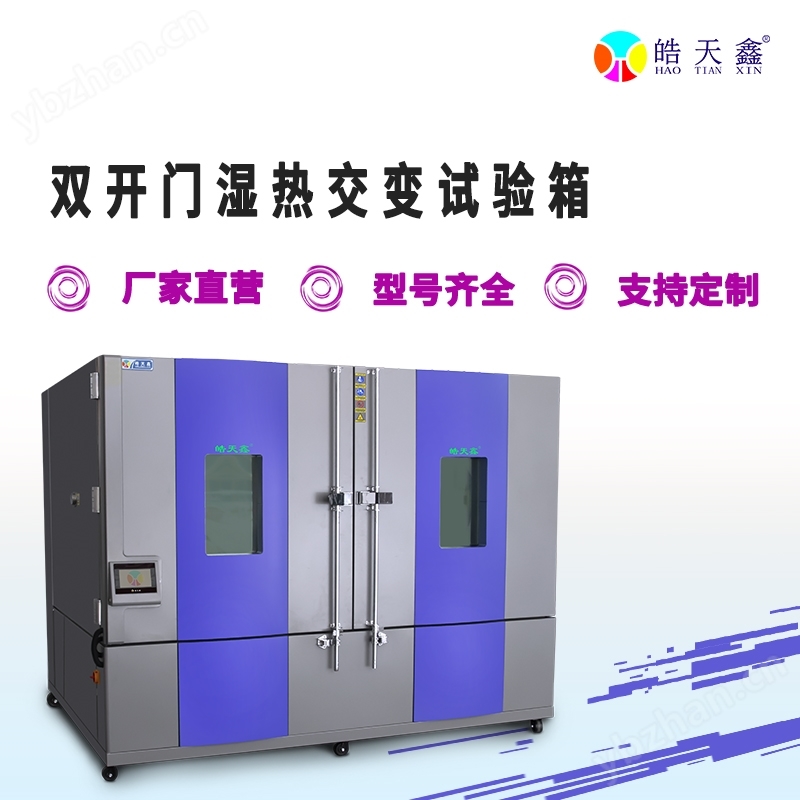

Box door designThe double door design facilitates the retrieval and placement of large-sized samples, and the box door should be equipped with a good sealing strip, such as silicone foam, to ensure effective isolation of the box environment from the outside when closed. At the same time, the embedded non reactive flat handle is easy to operate.

Programmable humidity and heat environment simulation aging test in high and low temperature test chamber

Static environment simulation: capable of maintaining a fixed temperature and humidity value for a long time (such as a high temperature and high humidity environment of 40 ℃ and 85% RH), to assess the aging, corrosion, and performance degradation of samples in a constant environment.

Dynamic cycle testing: Temperature and humidity alternating cycles can be implemented according to preset programs (such as -40 ℃~85 ℃ high and low temperature cycles, 25 ℃/50% RH → 60 ℃/90% RH → 25 ℃/50% RH temperature and humidity cycles), simulating the environmental changes encountered by the sample in actual use and testing its ability to resist environmental changes.

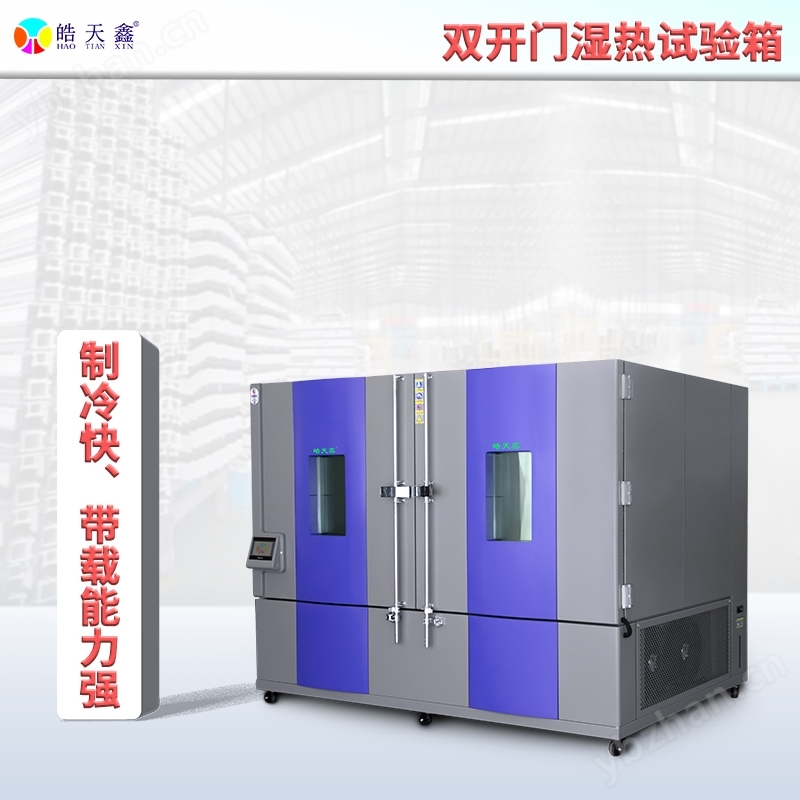

Fast temperature change/wet heat alternation: Some models support fast temperature change (temperature change rate can reach 5 ℃/min~15 ℃/min) and wet heat alternation, meeting the strict testing requirements of the automotive, electronics and other industries for the rapid environmental adaptability of samples.

It should have basic safety functions such as over temperature protection, overload protection, and leakage protection. In addition, water shortage protection, condensate overflow protection, threshold protection, etc. can also be considered to further improve the safety and reliability of the equipment.

Refrigeration and humidification system

refrigeration systemThe compressor is the core of the refrigeration system, with stable performance and high refrigeration efficiency. The fully enclosed design can effectively reduce the risk of refrigerant leakage. The quality of refrigeration components such as expansion valves, evaporators, condensers, etc. also directly affects the refrigeration effect. High quality components should be selected, and environmentally friendly refrigerants should also be used.

Humidification systemSplit type humidification cylinder design is quite common, which ensures uniform humidification and high efficiency. The capacity of the built-in stainless steel water tank is generally around 15L, which can meet the humidification needs for a certain period of time. At the same time, it has an automatic water replenishment device, which can achieve automatic water replenishment and reduce manual intervention.

Core principle: Regular cleaning, inspection of key components, and maintenance of system operation status can not only extend equipment life, but also ensure temperature and humidity control accuracy and testing reliability,

Refrigeration system inspection: Check for leaks in the refrigerant piping (no frost or oil stains on the surface of the piping); Check whether the noise and vibration of the compressor during operation are normal, and whether there is any abnormal heating.

Deep maintenance of humidification/dehumidification system:

Humidifier tank (if replaceable): If the effluent is turbid and heavily scaled, simply replace it with a new humidifier tank.

Dehumidification evaporator: If there is stubborn scale, soak it in a neutral descaling agent for cleaning (avoid using strong acids or alkalis), rinse it clean, and then air dry before installation.

Drainage system dredging: Rinse the drainage pipeline with clean water, and if necessary, use a fine soft pipe to clear the pipeline to avoid blockage and overflow of accumulated water.