-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

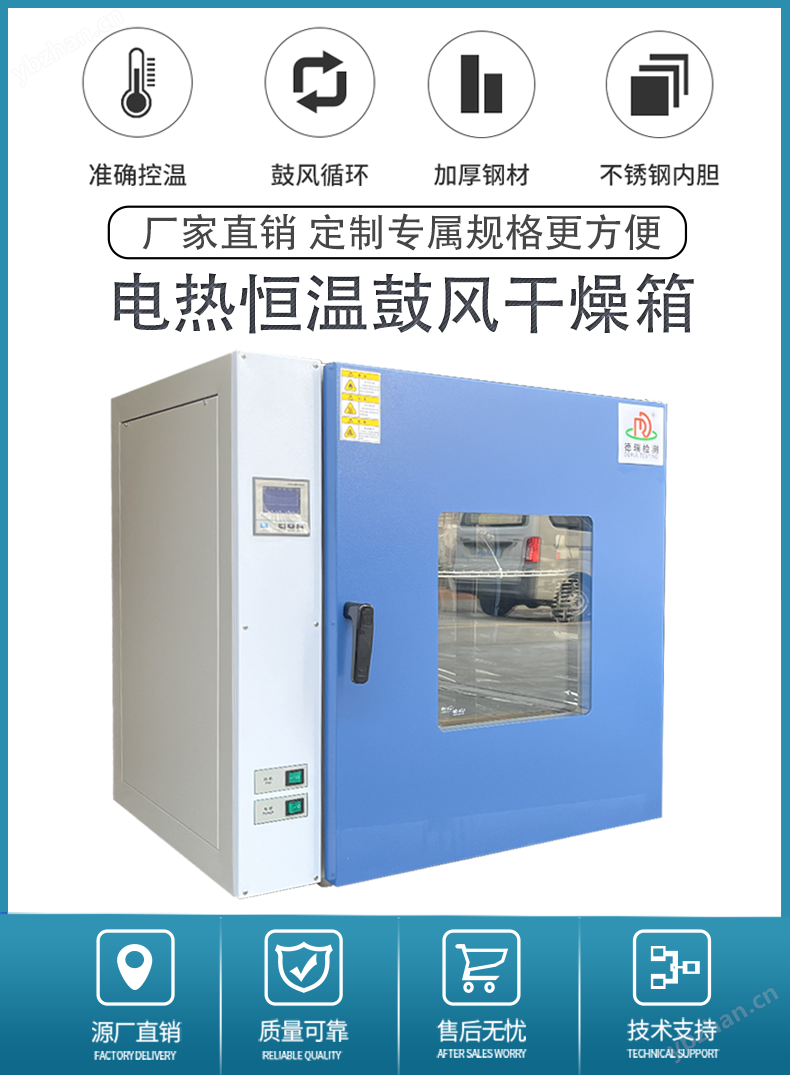

Rapid heating constant temperature electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Efficient drying and precise temperature control of samples are key steps in ensuring experimental results or product quality in laboratory research, industrial production, and material processing.Rapid heating constant temperature electric blast drying ovenAs the core equipment in this field, its design integrates thermodynamic principles and automation control technology to provide users with a stable and efficient heat treatment environment. This article will explore the technical principles, core advantages, and practical application scenarios of such devicespriceValue.

1、 The implementation logic of rapid heating

Problem introductionWhy is the heating rate of traditional drying ovens slower? How to achieve rapid heating through technological improvements?

Traditional drying ovens rely on natural convection to transfer heat, and their thermal efficiency is limited by the air flow velocity and heat transfer path. The constant temperature electric blast drying oven breaks through this limitation through the following design:

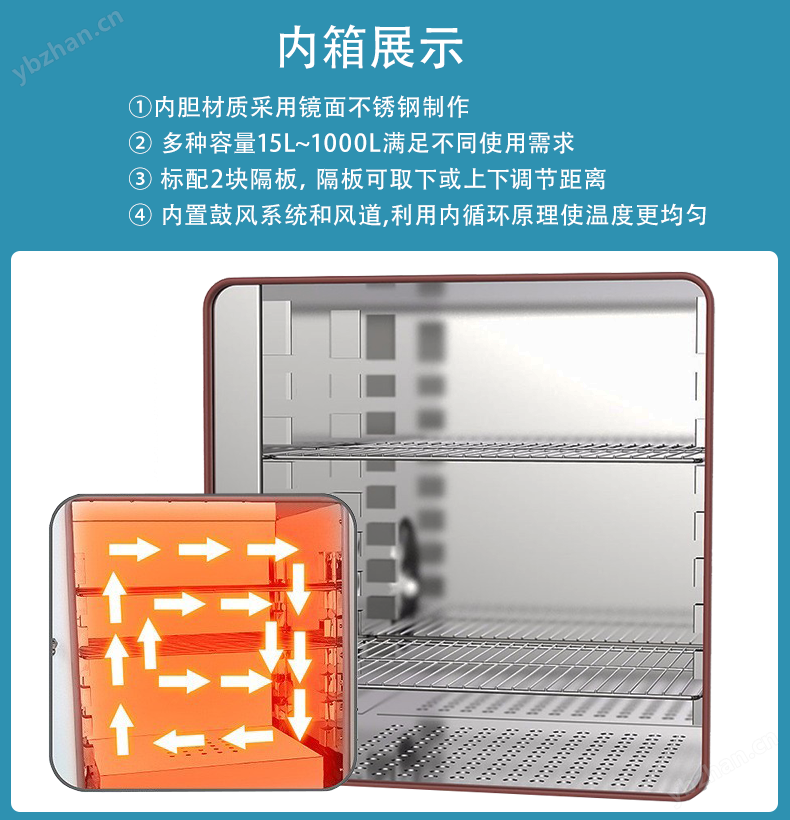

Forced hot air circulation systemBuilt in high-temperature resistant fan and optimized air duct design quickly distribute the heat generated by the heating element to the entire cavity, reducing local temperature gradients.

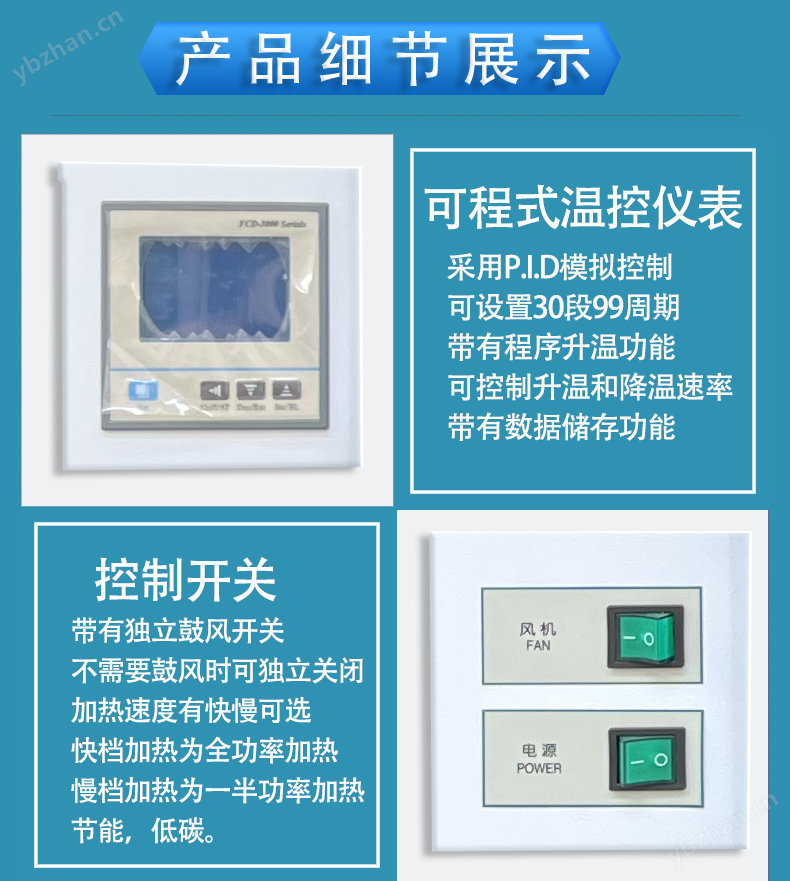

Efficient heating element layoutUsing multi zone distributed electric heating tubes or far-infrared heaters, combined with PID temperature control algorithm, to ensure uniform heat release and rapid response to temperature changes.

Low thermal inertia materialThe box is made of lightweight and high thermal conductivity materials (such as special alloys or composite insulation layers) to shorten the thermal response time of the heating system.

For example, in the food industry, a certain model of equipment can raise the chamber temperature from room temperature to 180 ℃ within 30 minutes, significantly better than the 1-hour heating time of traditional equipment.

2、 Technical points of constant temperature control

Problem introductionHow to achieve temperature stability at ± 0.5 ℃ level? What factors may affect temperature control accuracy?

Constant temperature control relies on the synergy of three technologies:

Sensor feedbackHigh precision platinum resistance (PT100) real-time monitoring of chamber temperature, with a sampling frequency of up to once per second.

PID intelligent regulationDynamically adjust heating power through proportional integral derivative algorithm to avoid temperature overshoot or hysteresis.

Air duct optimizationMulti layer baffle design ensures uniform airflow coverage of the sample area, reducing local temperature differences caused by air entrapment.

Key factors affecting temperature control accuracy:

| factor | influence | Solution |

|---|---|---|

| Environmental temperature fluctuations | External temperature changes interfere with system stability | Increase the thickness of the insulation layer of the box body |

| Sample heat capacity difference | High quality samples absorb heat, leading to a decrease in temperature | Reserved dynamic compensation power |

| Blowing system noise | Air flow disturbance causes sensor misreading | Adopting low vibration fan |

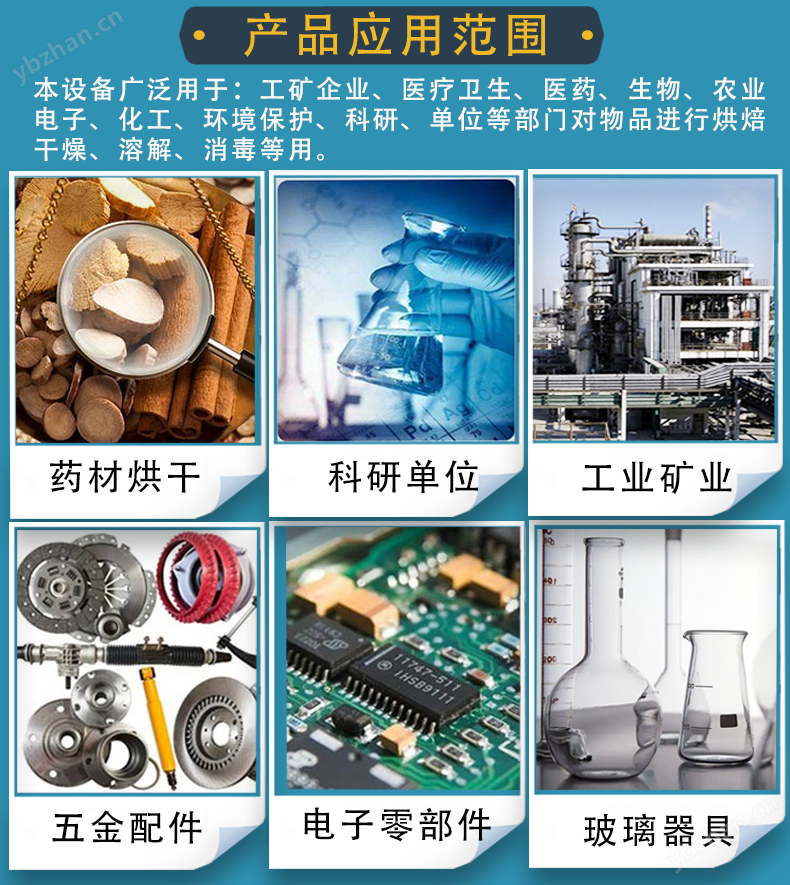

3、 Typical application scenario analysis

Problem introductionIn which industry scenarios is the rapid heating constant temperature drying oven usedcrucial?

laboratory research

Materials ScienceCeramic sintering, polymer curing and other processes require strict control of heating rate and insulation time.

BiochemistryWhen drying the culture medium and removing the sample solvent, a constant temperature environment can prevent the degradation of active ingredients.

environmental monitoringDuring the drying process of soil or sediment, temperature fluctuations may cause changes in particle structure, affecting the detection data.

industrial production

electronics manufacturingCircuit board drying should avoid high temperature overshoot that can cause solder joint failure, while quickly heating up to reduce production cycles.

food processingMeat or fruit and vegetable drying requires precise control of moisture content to prevent nutrient loss.

pharmaceutical industryThe sterilization and drying of drugs must comply with GMP standards, and the constant temperature system ensures batch consistency.

specialized field

cultural relics preservationThe slow drying of unearthed cultural relics should avoid cracking caused by sudden changes in temperature and humidity.

new energyThe drying of lithium battery electrode materials requires strict control of moisture content, which affects battery performance.

Case Comparison:

| scene | Pain points of traditional equipment | Advantages of rapid heating drying oven |

|---|---|---|

| Drying of laboratory glassware | Natural drying takes a long time and is prone to bacterial growth | 80 ℃ constant temperature drying for 1 hour improves sterilization rate |

| Electronic component packaging | Uneven temperature in ordinary ovens leads to poor curing of glue | Forced circulation improves curing uniformity by 30% |

4、 Selection and usage suggestions

Selection of core parameters:

temperature rangeConventional laboratory requirements are mostly room temperature+10 ℃~250 ℃, and high-temperature industrial scenarios need to be extended to above 300 ℃.

temperature control accuracyFor scientific research grade equipment, it is recommended to choose a fluctuation within ± 0.5 ℃, while for industrial grade equipment, ± 1 ℃ is acceptable.

Capacity and energy consumptionSelect the cavity size based on the sample volume to avoid reducing thermal efficiency due to overload.

Key points of daily maintenance:

Regularly clean the dust in the air duct to prevent blockages from affecting airflow distribution.

Check the heating element connectors to avoid power attenuation caused by poor contact.

For corrosive gas environments (such as dry acidic samples), anti-corrosion coating inner liners should be selected.

5、 Technological Deepening: Safety Design and Energy Efficiency Optimization

Problem introductionHow to ensure operational safety and reduce energy consumption during high-temperature operation?

Multiple security protections:

Overtemperature alarm and power-off protectionWhen the temperature exceeds the set threshold, the system automatically cuts off the heating power to prevent damage to the sample or equipment.

Pressure relief mechanismWhen the air pressure inside the box is abnormal, the pressure relief plate will automatically open to avoid accidents caused by pressure accumulation.

Anti scald designThe shell is made of insulation material, and the door seal structure is optimized to reduce the risk of external contact.

Energy efficiency improvement strategy:

heat recoveryBy designing the return air chamber, some of the waste heat is reintroduced into the heating system to reduce overall energy consumption.

Intelligent start stopAutomatically start and stop according to the preset program to reduce unnecessary running time.

Modular structureSupport the replacement of high-efficiency energy-saving components (such as variable frequency motors) to meet different energy efficiency requirements.

Conclusion

Rapid heating constant temperature electric blast drying ovenThrough the deep integration of thermodynamics and automation technology, efficient and accurate heat treatment solutions have been provided for various industries. Whether it is basic scientific research or complex industrial production, its value lies not only in hardware performance, but also in how to meet diverse application scenario requirements through reasonable design.